Solvent resistant polyamide nanofiltration membranes

a technology of nanofiltration membrane and solvent resistance, which is applied in the direction of membranes, filtration separation, separation processes, etc., can solve the problems that the thin film composite membranes of the prior art fabricated with such supports cannot be effectively utilized for all organic solvent nanofiltration applications, and the solute separation of organic solvents is not widely applied. , to achieve the effect of high flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0096]In the following example, membranes of the present invention are formed through interfacial polymerisation to form a polyamide on a crosslinked polyimide support membrane, as follows:

[0097]Formation of Crosslinked Polyimide Support Membrane

[0098]A polymer dope solution was prepared by dissolving 24% (w / w) polyimide (P84 from Evonik AG) in DMSO and stiffing overnight until complete dissolution. A viscous solution was formed, and allowed to stand for 10 hours to remove air bubbles. The dope solution was then cast on a polyester or polypropylene (Viledon, Germany) non-woven backing material taped to a glass plate using a casting knife (Elcometer 3700) set at a thickness of 250 Immediately after casting, the membrane was immersed in a water bath where phase inversion occurred. After 15 minutes, it was changed to a new water bath and left for an hour. The wet membrane was then immersed in a solvent exchange bath (isopropanol) to remove any residual water and preparation solvents.

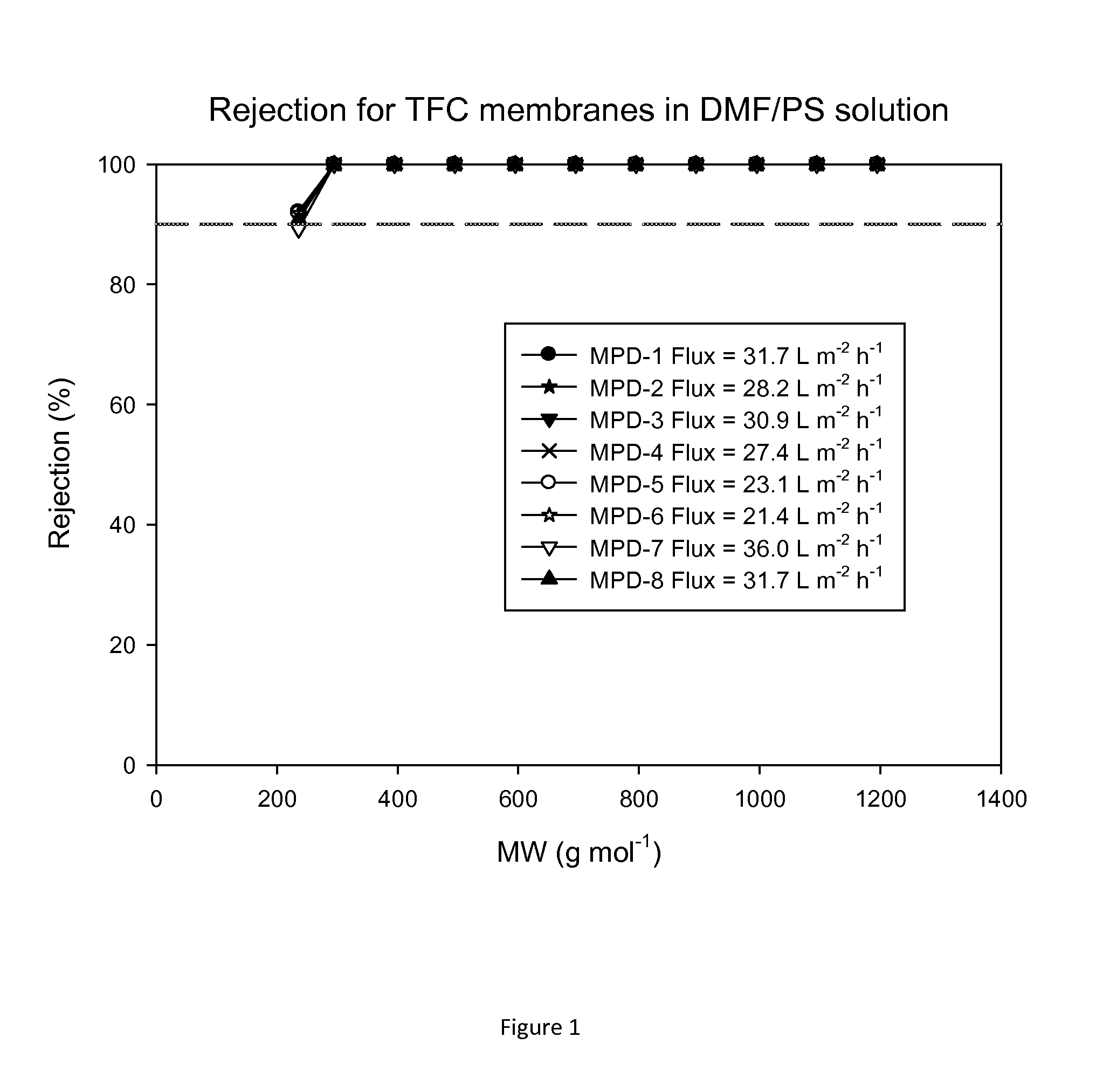

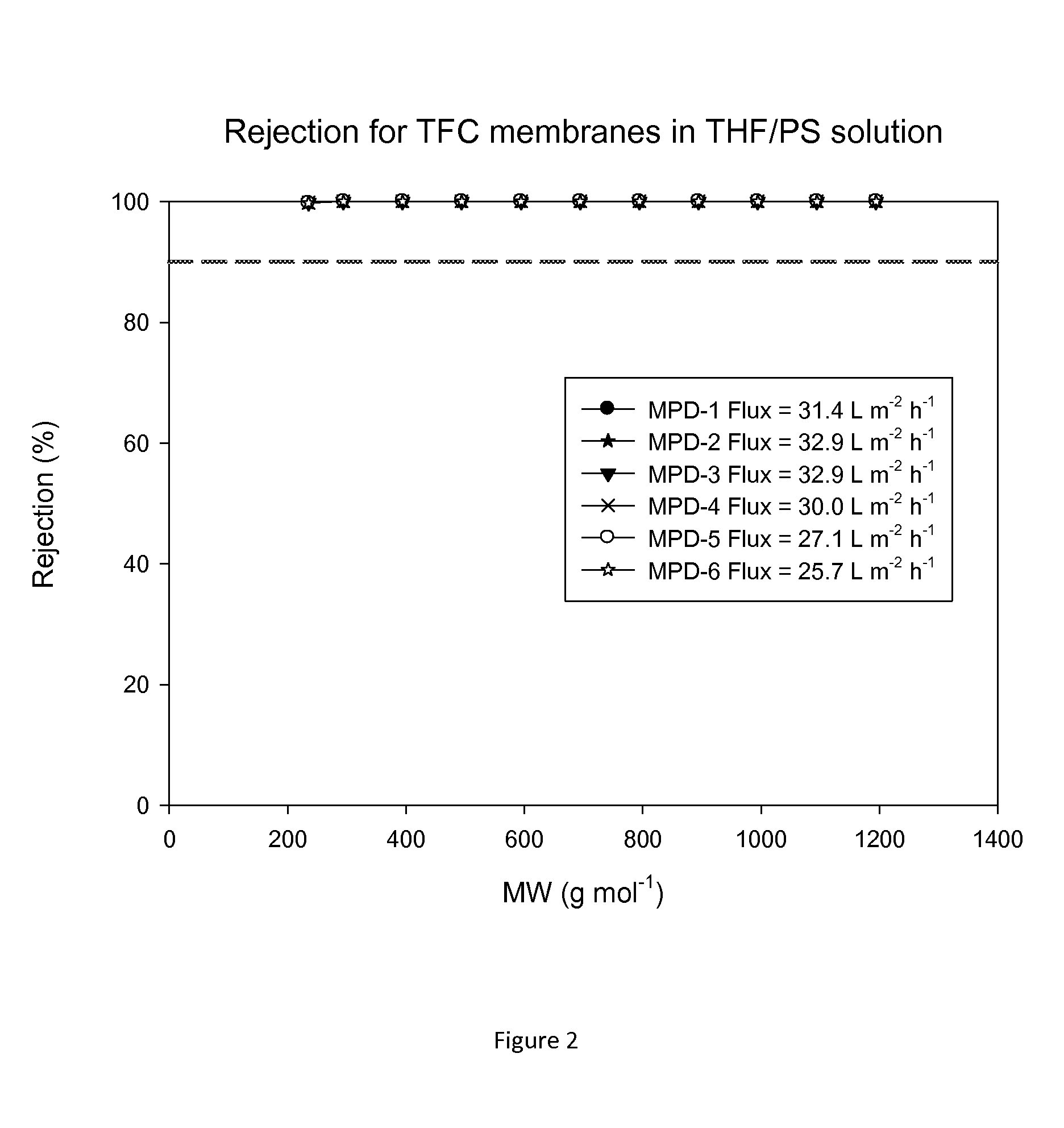

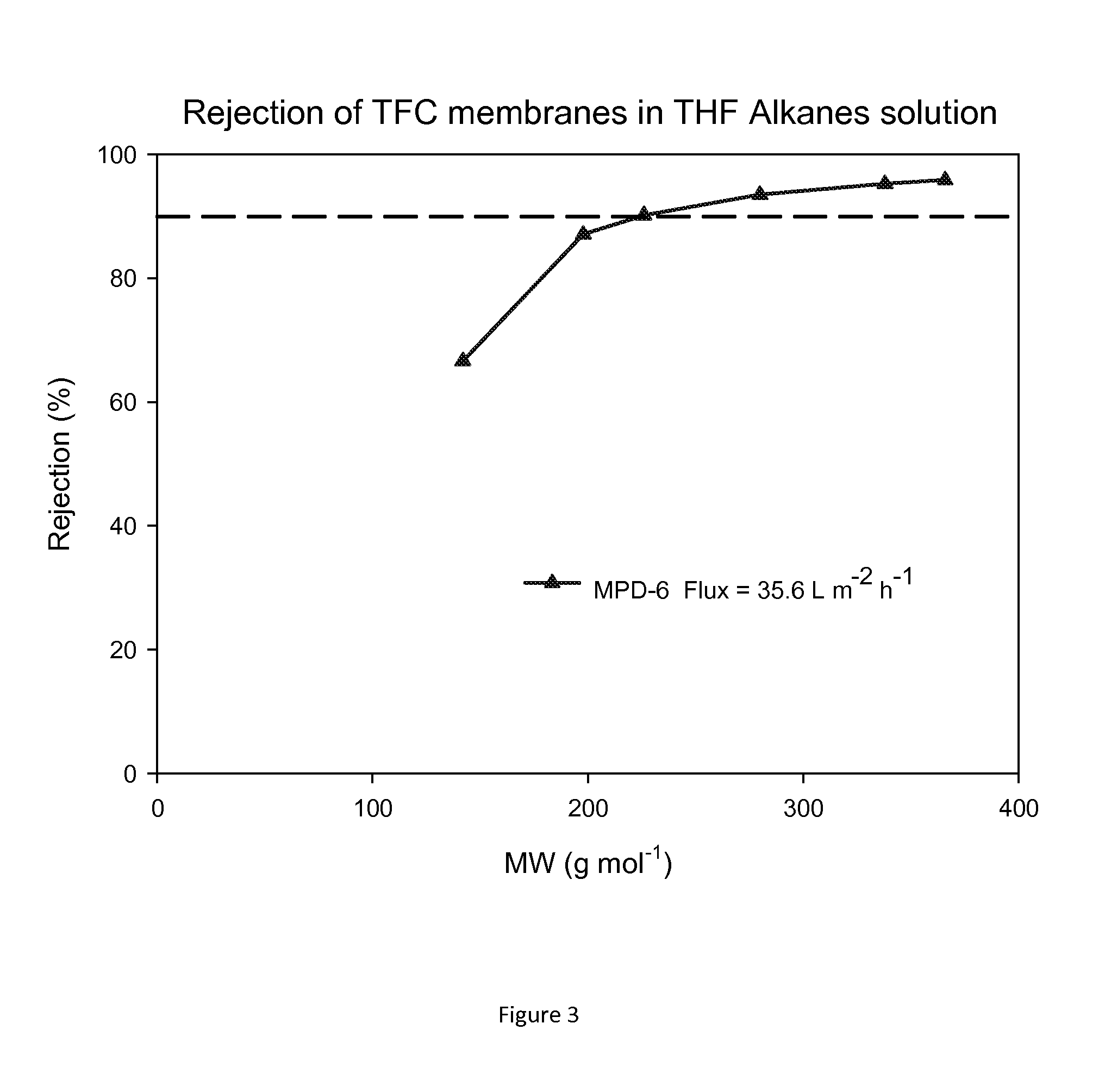

[0...

example 2

[0108]TFC membranes were fabricated as per EXAMPLE 1. Post-formation step (d) (contacting with DMF as an activating solvent) was only performed for some of the membranes. The performance of TFC membranes with and without the activation step (d) contacting with DMF was evaluated in different solvents, including acetone, methanol, ethyl acetate and toluene.

[0109]For the MWCO curves and flux test in MeOH, acetone, toluene and ethyl acetate with and without contacting with DMF, eight new MPD membranes were tested at each time and the results for both rejection and flux were reproducible.

[0110]FIG. 4 shows rejection curves and flux for TFC membranes in acetone / PS without treating the membrane with an activating solvent. FIG. 5 shows rejection curves and flux for TFC membranes during nanofiltration of acetone / PS solution after treating the membranes with DMF.

[0111]FIG. 6 shows rejection curves and flux for TFC membranes during nanofiltration of MeOH / PS without treating the membrane with a...

example 3

[0114]Membrane supports were fabricated as per EXAMPLE 1 but were not conditioned with PEG. TFC membranes were fabricated on these non-conditioned support membranes as per EXAMPLE 1. The performance of TFC membranes prepared on membrane supports with and without PEG was then evaluated and compared.

[0115]Membrane identification codes for the TFC membranes prepared in this Example are as follows:

EntryMembraneNo.Membranecode2TFC membrane prepared on crosslinked PI asMPD-nsupport impregnated with PEG3TFC membrane prepared on crosslinked PI supportMPD-NP-nnot impregnated with PEGWhere n identifies membranes made in independent batch n.

[0116]FIG. 10 shows rejection curves and flux for TFC membranes prepared on membrane supports without PEG in DMF / PS solution. FIG. 11 shows rejection curves and flux for TFC membranes prepared on membrane supports with PEG in DMF / PS solution. An increase in flux can be observed when TFC membranes are prepared on membrane supports containing PEG.

[0117]In thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com