Systems and methods for fabrication of nanostructures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

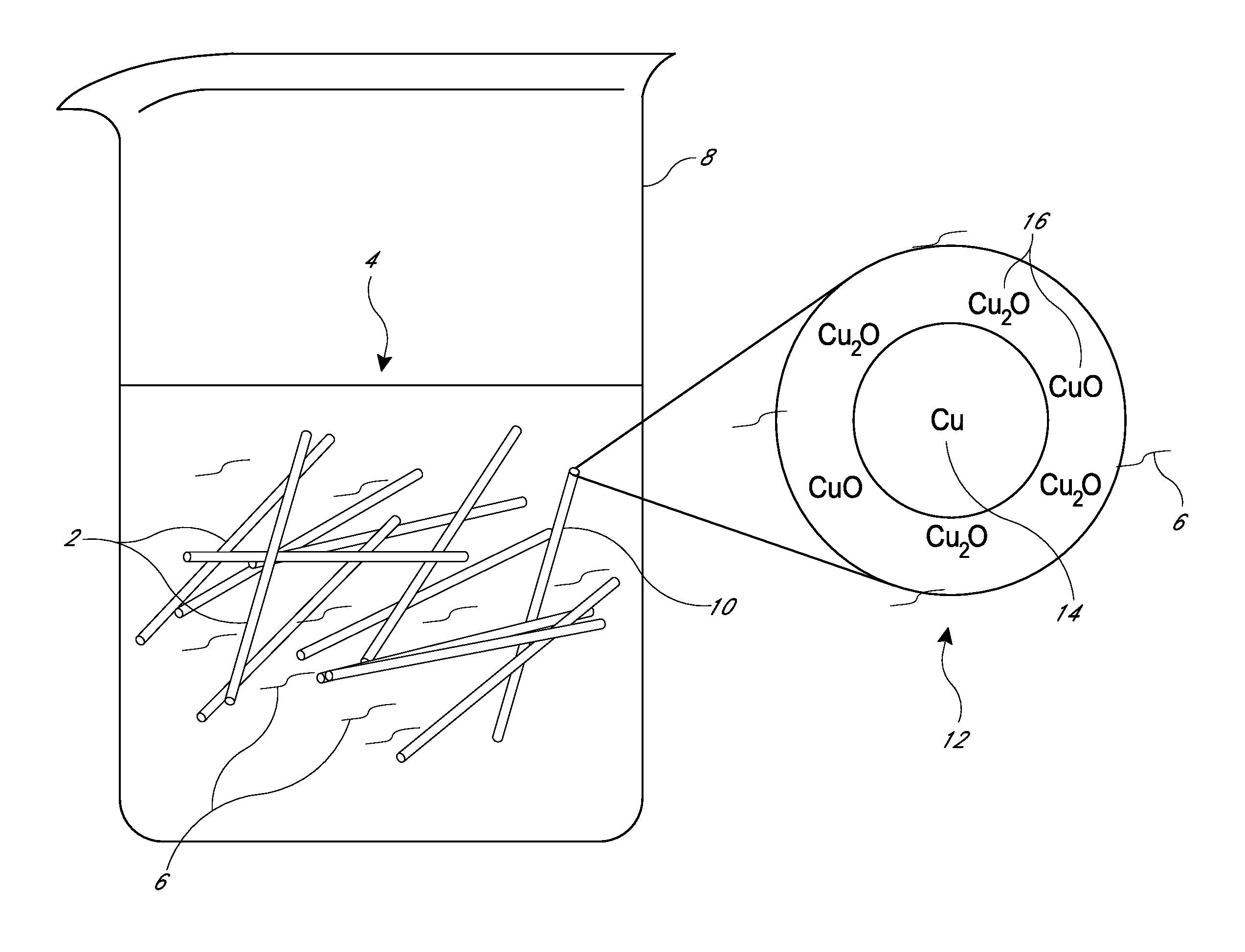

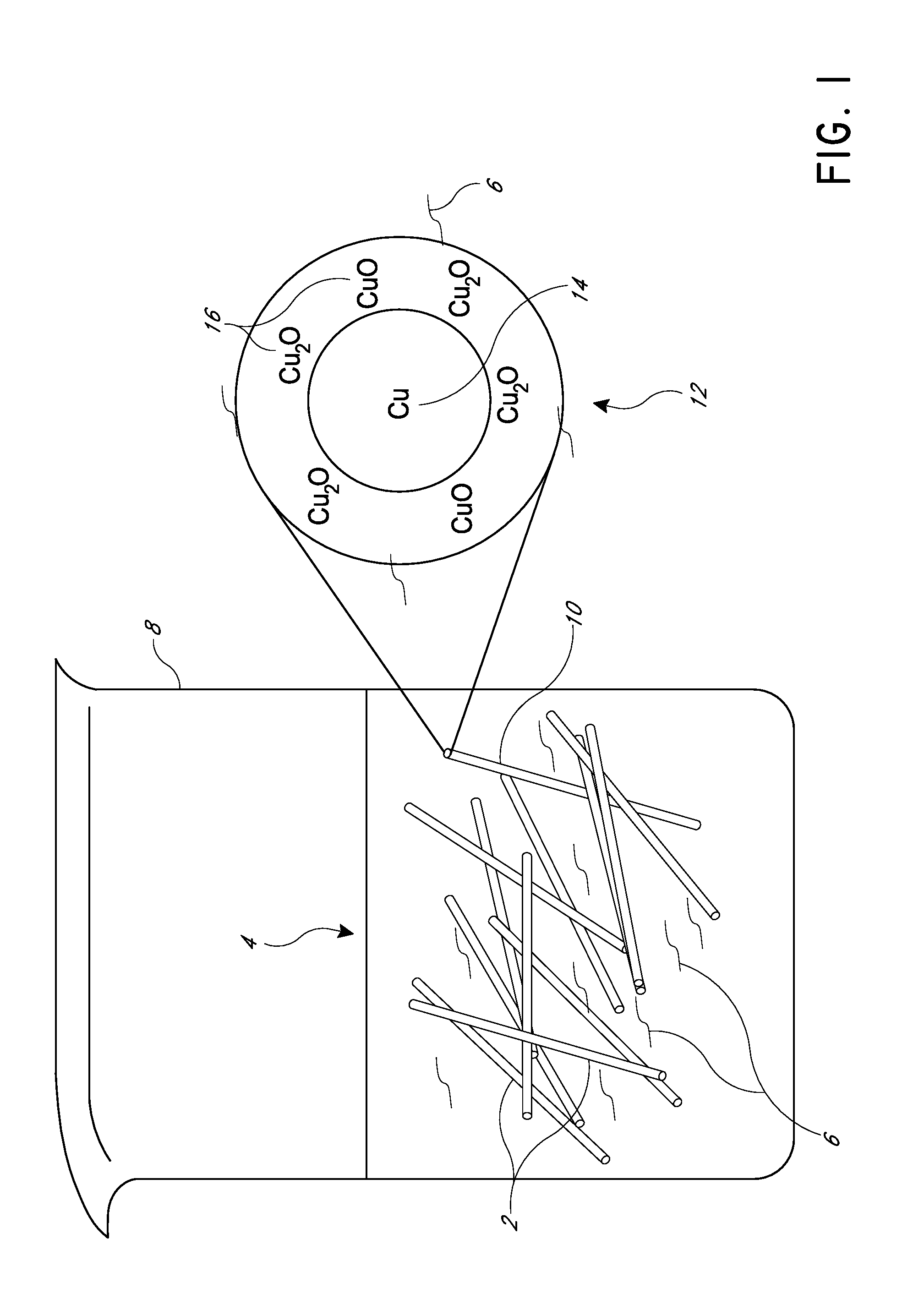

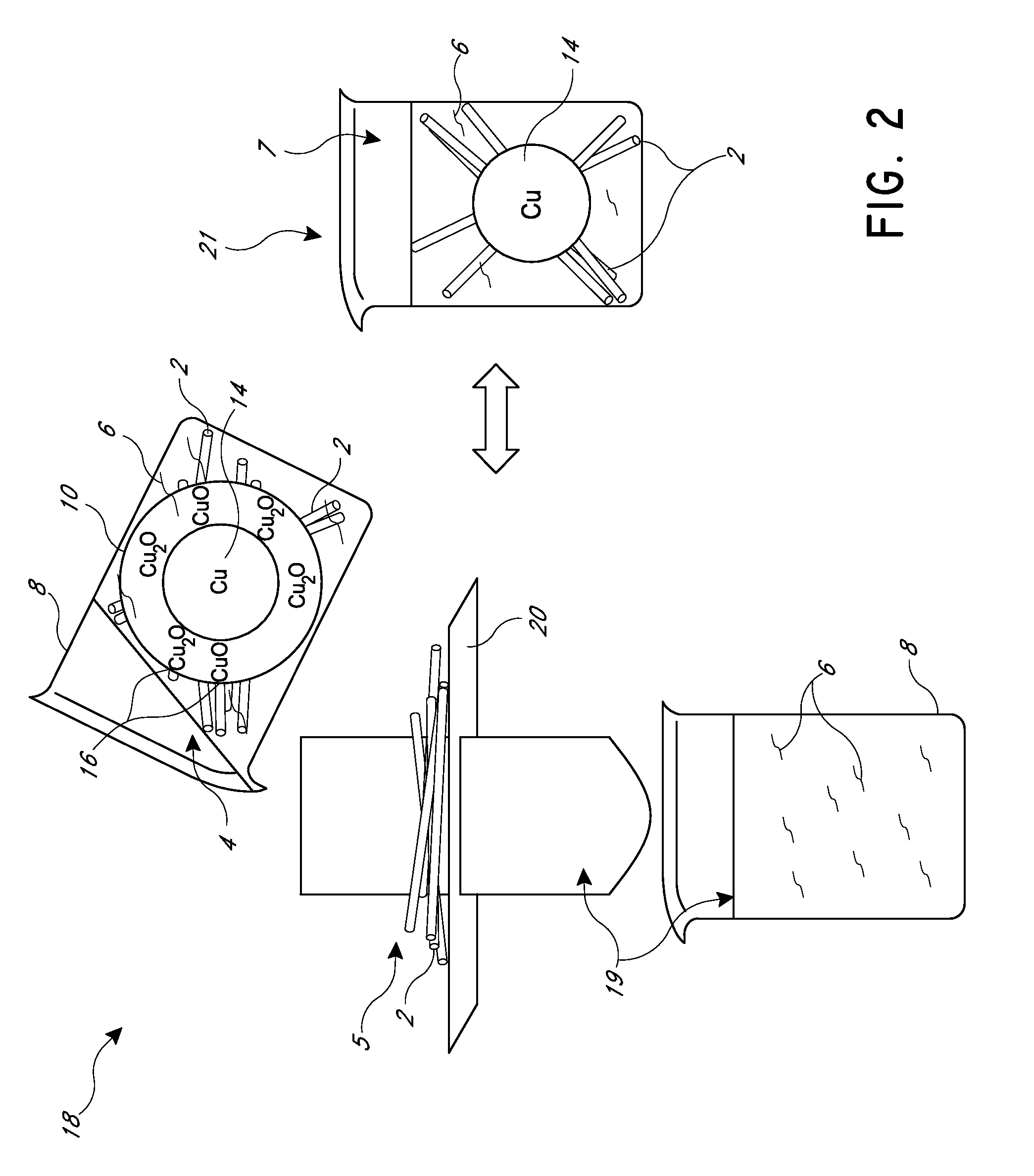

embodiment 1

[0049]2. The method of Embodiment 1, wherein the nanostructures comprise nanowires.

[0050]3. The method of Embodiment 1 or 2, wherein the first element is copper.

[0051]4. The method of any of Embodiments 1-3, wherein the second element is silver.

[0052]5. The method of any of Embodiments 1-4, wherein a concentration of the nanostructures in the dispersion is between about 0.1 g / L and about 1 g / L.

[0053]6. The method of any of Embodiments 1-5, wherein the dispersion includes at least one of dispersants and surfactants.

[0054]7. The method of any of Embodiments 1-6, wherein the dispersion includes polyvinylpyrrolidone.

[0055]8. The method of any of Embodiments 1-7, wherein the dispersion includes bile salts.

[0056]9. The method of any of Embodiments 1-8, wherein the dispersion includes water.

[0057]10. The method of any of Embodiments 1-9, wherein the dispersion includes organic solvent.

embodiment 10

[0058]11. The method of Embodiment 10, wherein the organic solvent comprises ethanol.

[0059]12. The method of any of Embodiments 1-11, wherein a concentration of the reagent solution is between about 0.1 M and about 0.15 M.

[0060]13. The method of any of Embodiments 1-12, wherein the reagent solution comprises a silver nitrate.

[0061]14. The method of any of Embodiments 1-13, wherein the reagent solution comprises silver ions.

[0062]15. The method of any of Embodiments 1-14, mixing comprises slowly adding the reagent solution.

embodiment 15

[0063]16. The method of Embodiment 15, wherein slowly adding comprises drop-wise adding.

[0064]17. The method of any of Embodiments 1-16, wherein mixing comprises vigorously stirring with a stirrer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com