Polyamide-imide coated substrate

a technology of polyamideimide and substrate, applied in the direction of record information storage, transportation and packaging, instruments, etc., can solve the problems of increasing manufacturing costs, introducing environmental and safety issues, increasing the cost of manufacturing automotive parts, etc., and achieves cost savings, excellent performance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Aqueous Polyamide-Amic Acid Solution

[0031]200 g of polyamide amic acid (TORLON® Al-50 from Solvay Advanced Polymers, available as wet powder with a solids content of 35 wt %, is dispersed in a mixture of water (485 g) and dimethyl ethanol amine (50 g). The dispersion is then warmed to a temperature between 60 and 70° C. until the solids dissolve to produce a brown aqueous solution having about 9% by weight polyamide-amic acid.

example 2

Application of the Aqueous Polyamide-Amic Acid Solution

[0032]The aqueous polyamide-amic acid solution is cooled to room temperature and 0.5 wt % of wetting agent BYK® 380N (from Byk Chemie) is added thereto. This solution is applied on a galvanised steel strip by roller coating at a speed of 150-250 m / min. The applied coating is then cured via near-infrared at s temperature of 260° C. for 5-10 s to remove the aqueous solvent and form a layer of polyamide-imide on the galvanised steel strip surface.

Experiments

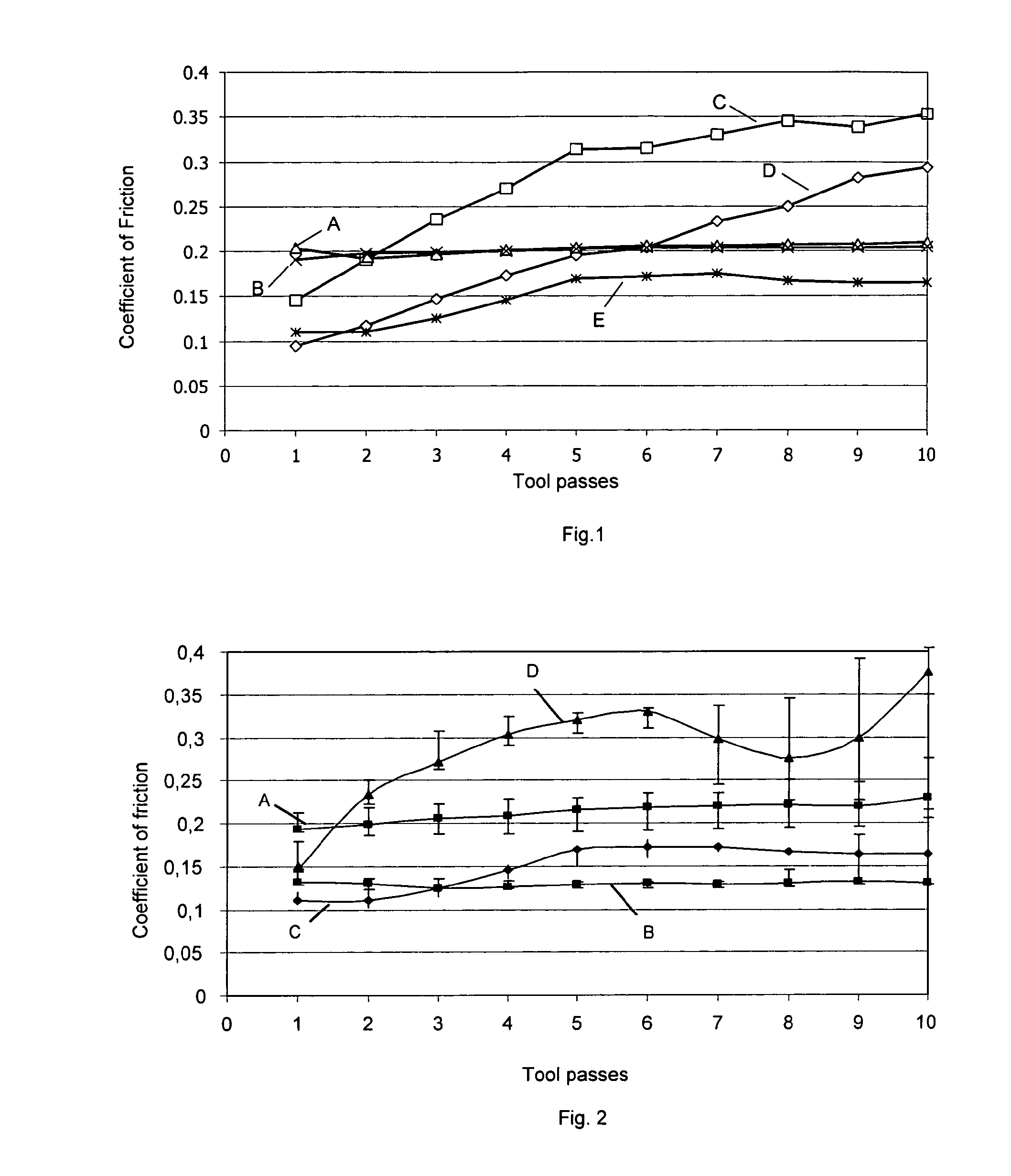

[0033]In the experiments hereunder the layer of polyamide-imide has been applied on a galvanised steel strip (E1).The present invention (E1) has been compared to a number of commercial coating systems that are used in the automotive industry to reduce the effects of corrosion caused by surface defects, scratches and cut edges. C1-C3 are comparative examples in which galvanised steel strips have been provided with titanium phosphate (C1), a layer of acrylic containing chromate pi...

experiment 1

est

[0035]In order to evaluate the performance of the layer polyamide-imide in respect of its corrosion resistance the coated steel strip of the invention was subjected to a salt spray test. The salt spray test was performed according to ASTM B117, using a 5% NaCl solution at 35° C., with an overpressure of 2-3.5 mbar (200 to 350 Pascal) to create fog inside the spray chamber.

[0036]Table 1 shows the corrosion resistance properties of a galvanised steel strip provided with a layer of polyamide-imide (E1-E4) and comparative examples C1-C4. All thicknesses relate to the thickness of the respective layers, i.e. exclusive of the underlying galvanised coating layer. It can be seen from Table 1 that the present invention El offers a significant improvement in corrosion resistance relative to C1-03 with just 2% white rust being observed after 15 days and 5% white rust being observed after 25 days. Similar results are obtained for examples E2-E4. The observed improvement in corrosion resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com