Hydrophobin mimics: process for preparation thereof

a technology of hydrophobin and mimics, applied in the field of hydrophobin mimics, can solve the problems of limiting protein nanotechnology application, difficult to predict the effects of various mutations, and high-throughput screening which may not be feasible for all proteins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

of 1-Tail (1T) Hydrophobic Azides

[0110]1.1 Synthesis of 4-hydroxybenzyl Alcohol

[0111]To a suspension of 4-hydroxybenzaldehyde in DCM, silica was added, followed by sodium borohydride. The reaction mixture was stirred for five minutes prior to the dropwise addition of methanol after which it was left to stir for a further thirty minutes. The entire reaction mixture was poured onto a short silica pad and was flushed with acetone. Combined organic layer was dried over Na2SO4 and evaporated under vacuum to get product which was used without further purification.

[0112]1.2 Synthesis of 1-Tail Alkyl Alcohol

[0113]4-hydroxybenzyl alcohol (1.0 eq), alkyl bromide (1.1 eq), K2CO3 (1.2 eq), crown ether (0.1 eq) were taken in an oven dried RBF. The flask was then purged with nitrogen and acetone was added under stirring to dissolve the mixture and refluxed for 24 hours. Upon completion, reaction mixture was concentrated and extracted thrice with DCM. Combined organic layer was dried over Na2SO4 a...

example 2

rocedures for Synthesis of 2-Tail (2T) Hydrophobic Azides

[0118]2.1 Synthesis of Ethyl 3, 5-dihydroxybenzoate

[0119]3,5-dihydroxybenzoic acid (35 g, 227 mmol) was taken in an oven dried RBF, ethyl alcohol (250 mL) was added and dissolved with stirring, sulphuric acid (24 mL) was added drop wise and refluxed for 22 hours. Upon completion, reaction mixture was neutralized with aqueous NaHCO3 and extracted thrice with ethyl acetate. The combined organic layer was washed with brine, dried over sodium sulphate (Na2SO4) and concentrated under vacuum to get crude product, which was further purified using silica gel column chromatography using ethyl acetate / hexane (30:70) to get white colour solid (41 g, 214 mmol, 94%).

[0120]2.2 Synthesis of 2-Tail Alkyl Esters

[0121]Ethyl 3,5-dihydroxy benzoate (1.0 eq), alkyl bromide (2.5 eq), K2CO3(3.5 eq), KI (0.05 eq) were taken in an oven dried RBF. The flask was then purged with nitrogen; DMF was added under stirring to dissolve the mixture and refluxed...

example 3

rocedure for Synthesis of 3-Tail (3T) Hydrophobic Azides

[0128]3.1 Synthesis of Ethyl 3,4,5-trihydroxybenzoate

[0129]To the stirring solution of 3,4,5-trihydroxybenzoic acid (6 g, 38 mmol) in ethyl alcohol (70 mL), sulphuric acid (4 mL) was added drop wise and refluxed for 22 hours. Reaction mixture was neutralized with aqueous Na2CO3 solution, extracted thrice with ethyl acetate. The combined organic layer was washed with brine and concentrated under vacuum to get crude product which was purified using silica gel column chromatography using ethyl acetate / hexane (30:70) to get white colour solid (6.73 g, 36 mmol, 95%).

[0130]3.2 Synthesis of 3-Tail Esters

[0131]Ethyl 3,4,5-trihydroxybenzoate of step (3.1) (1.0 eq), alkyl bromide (3.5 eq), K2CO3 (3.5 eq) and KI (0.05 eq) were taken in an oven dried flask. The flask was then purged with nitrogen; DMF was added under stirring to dissolve the mixture and refluxed for 12 hours. Upon completion, reaction mixture was neutralized with acidic wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

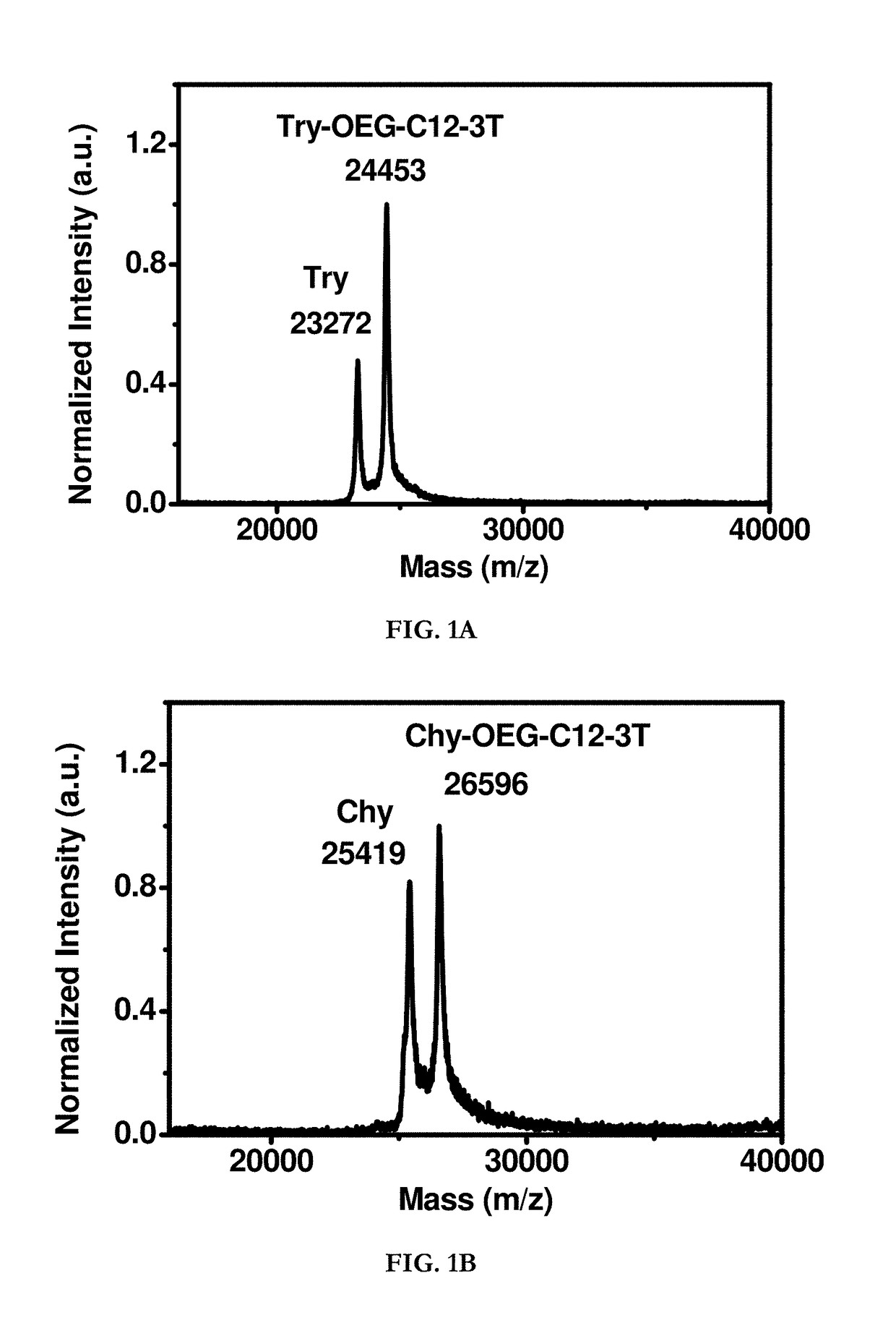

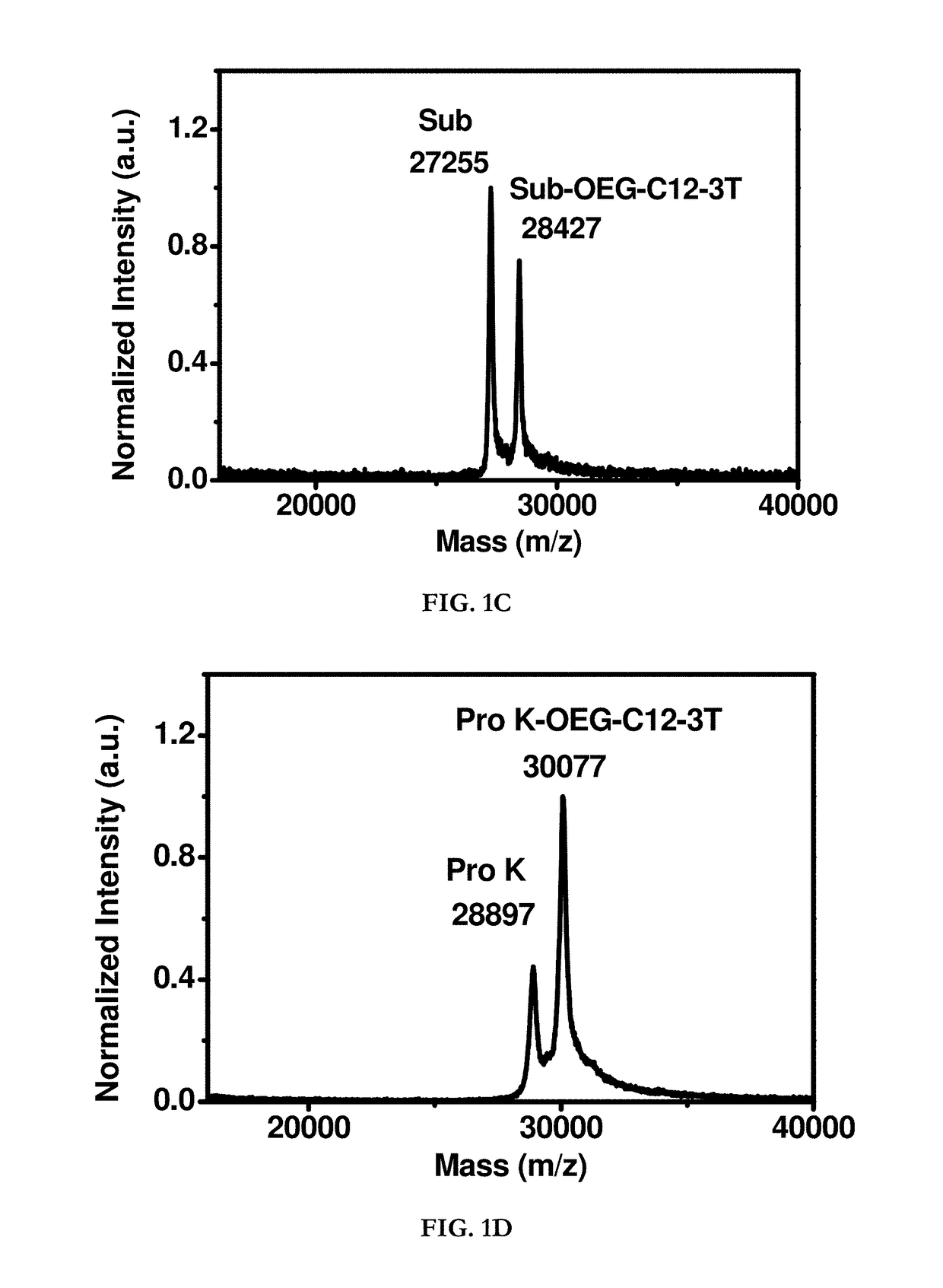

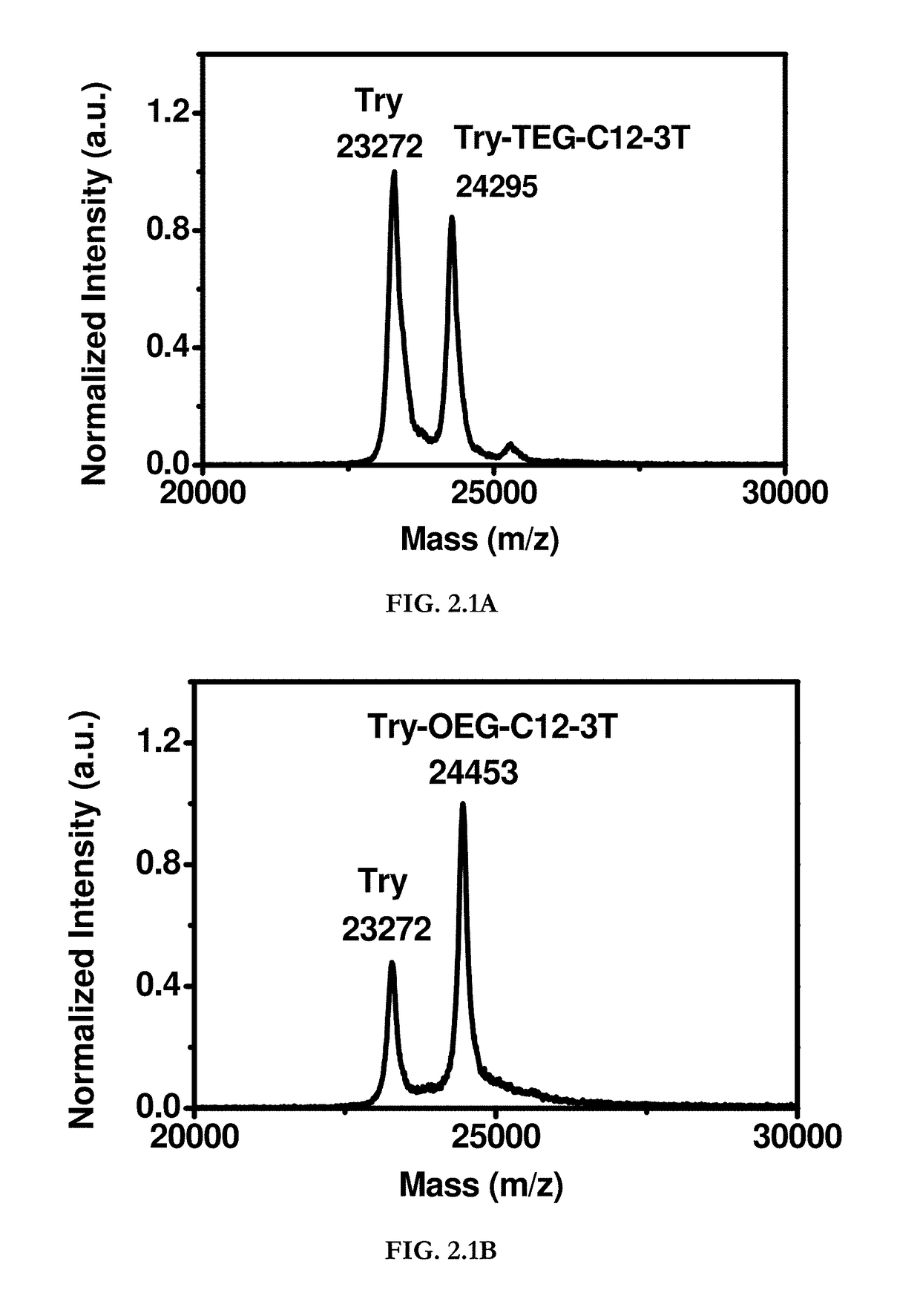

| molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com