Antibacterial Fibers and Materials

a technology applied in the field of antibacterial fibers and materials, can solve the problems of almost all of the antibacterial effectiveness lost, the antibacterial effectiveness of treated textiles is not adequately maintained, and the individual's harm is not sufficiently affected, so as to achieve the antibacterial effectiveness of the unwashed, the effect of uniform dispersion of antimicrobial nanoparticles and the retention of antibacterial effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example a

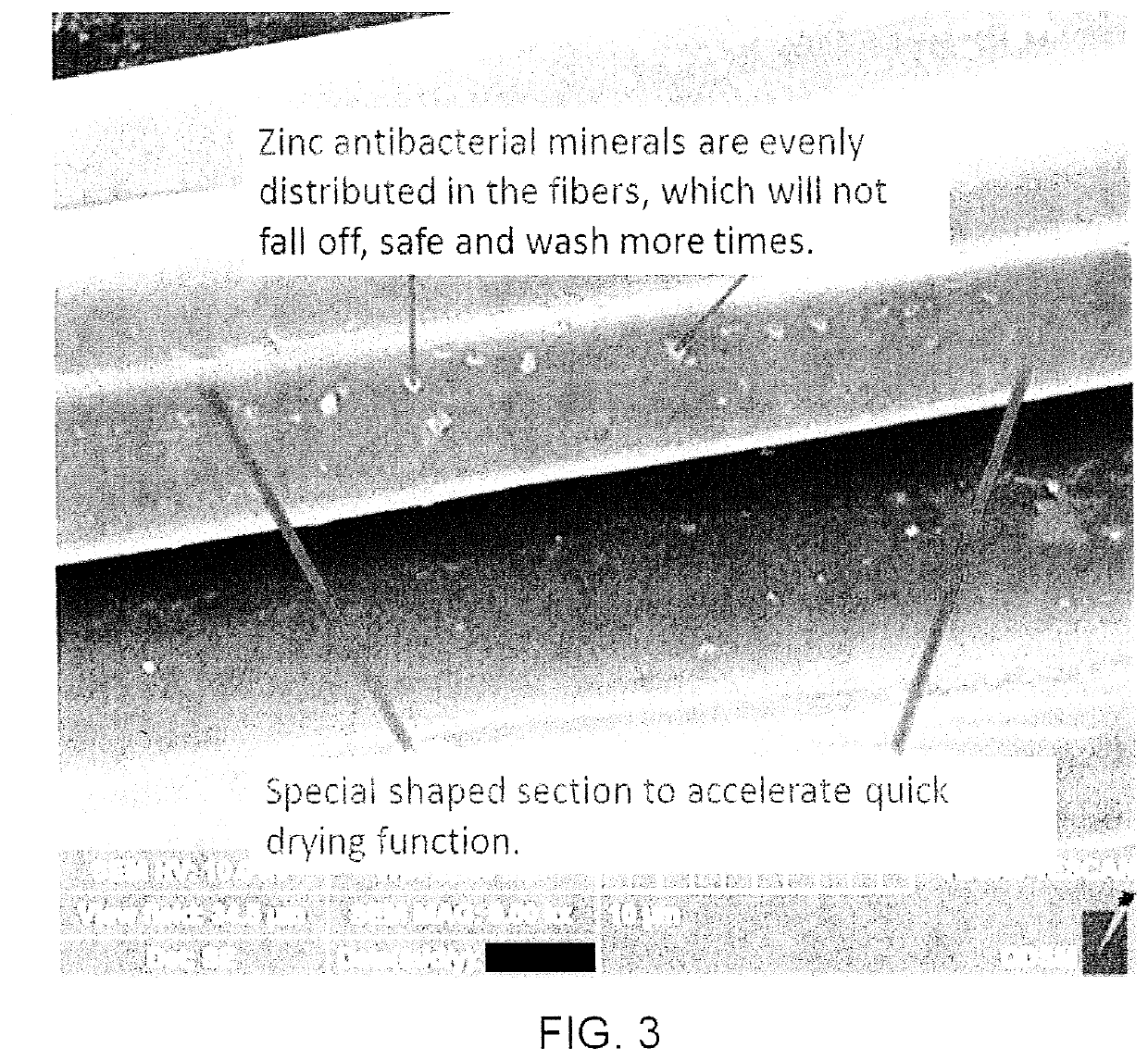

[0129](1) Nano-zinc powders, polyester chips, silane coupling agent, and surfactant were melted and mixed in a high shear mixer in sequence according to the technological process at 150° C. Thinning agent was optionally added to the mixture to obtain a target mixing viscosity. The composition was fully mixed and evenly stirred, and then granulated into a granulator to make the functional masterbatch. Based on the total mass of the functional masterbatch, the mass percentage of zinc powder was 20-30 wt. % and the silane coupling agents and surfactants constituted 0.001-10 wt. %.

[0130](2) The functional masterbatch and polyester chips were added into a spinning box, melted and mixed at 220° C., while stirred to ensure melting and even mixing and to produce mixed raw materials. The weight ratio of the polyester chips to the functional masterbatch was about 10:1 to 15:1.

[0131](3) When the mixed material was added to the screw extruder, the temperature in the heating box of the screw ext...

example b

[0136](1) This aspect was similar to Example 1, the difference being, according to the total mass of functional masterbatch, the mass percent of nanometer zinc powder was 25%, the mass percent of silane coupling agent and surfactant was 10%.

[0137](2) This aspect was similar to Example 1, the difference being that the temperature was 230° C.

[0138](3) This aspect was similar to Example 1, the difference being that the temperature of the heating box assembly of the screw extruder was 270° C.

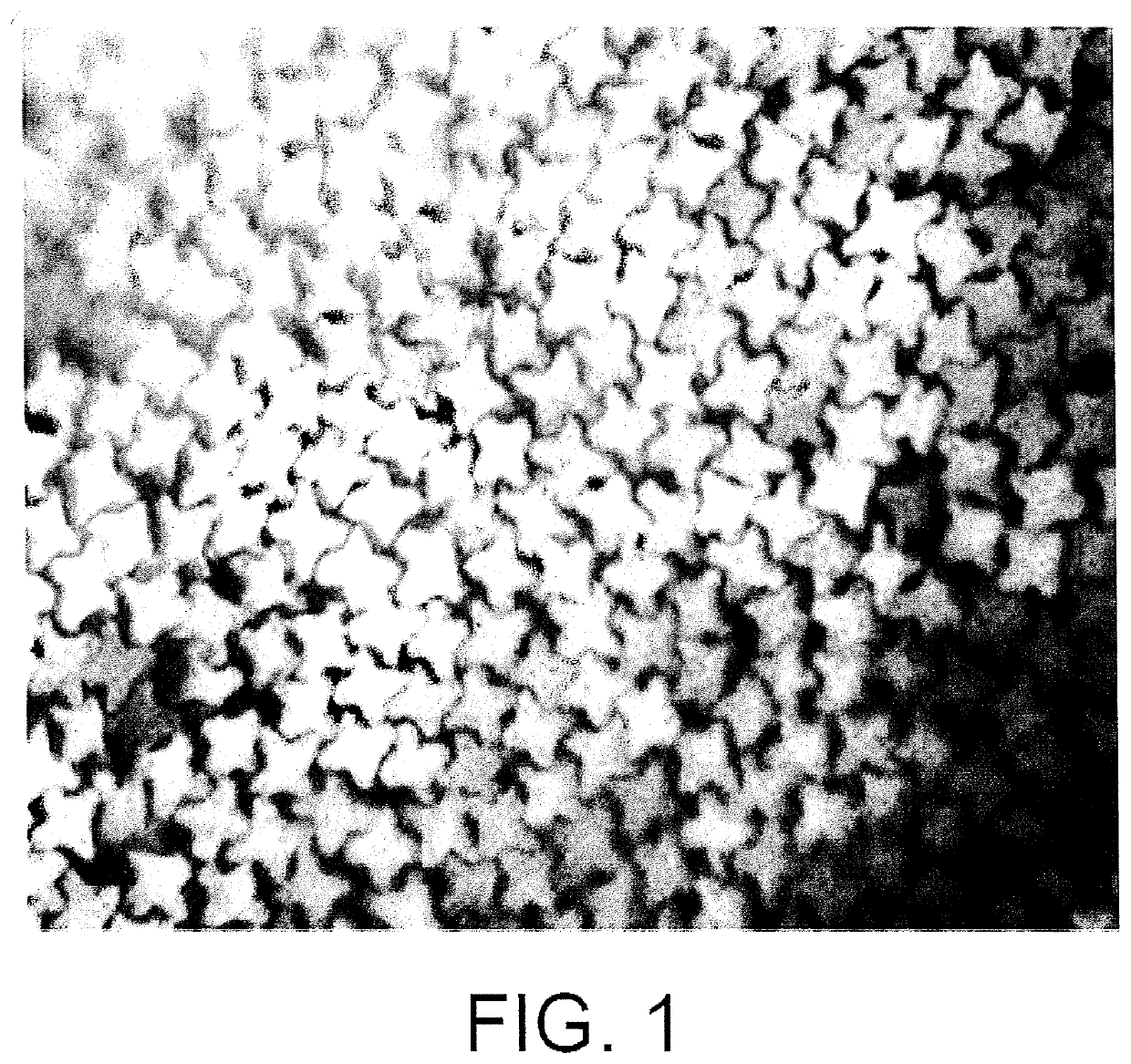

[0139](4) The above-mentioned special-shaped zinc antibacterial fibers, with clover- and cross-shaped cross sections, were wound and cooled by cross-blowing at 25° C.

[0140]The antibacterial activity of the zinc antibacterial fiber and the zinc antibacterial fiber after 100 washings were tested.

[0141]The results showed that the antibacterial rate of zinc antibacterial fiber to S. aureus (>95%), E. coli (>95%) and C. albicans (>90%) was high.

[0142]After 100 industrial washings, the bacteriostatic rate...

example c

[0143](1) 200-350 kg. of nano-zinc powders and 590-795 kg. PET chips where dry mixed together for about 2-20 minutes until the chips and powder are generally evenly mixed together.

[0144](2) Silane coupling agent and surfactant and optionally other materials (e.g., colorant, mica, thinning agent, tourmaline) are added to the mixture of nano-zinc powder and PET chips. The silane coupling agent and surfactant and optionally other materials can be added to the mixture of nano-zinc powder and PET chips prior to, during, or after the PET has been melted. About 2-10 kg. of silane coupling agent and surfactant and optionally about 1-120 kg. of thinning agent are used. About a 0.8:1 to 1.2:1 weight ratio of silane coupling agent to surfactant is used.

[0145](3) The mixture of nano-zinc powder and PET chips is heated to 165° C. to begin the melting of the PET chips. The silane coupling agent and surfactant and optionally other materials can be added to the mixture of nano-zinc powder and PET c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com