Shoe comprising a sole of a thermoplastic material and a method for use in manufacturing such a shoe

a thermoplastic material and sole technology, applied in the field of shoes, can solve the problems of long processing time, more complex, solvent-based adhesives are relatively expensive, etc., and achieve the effect of reducing the disadvantages of prior ar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

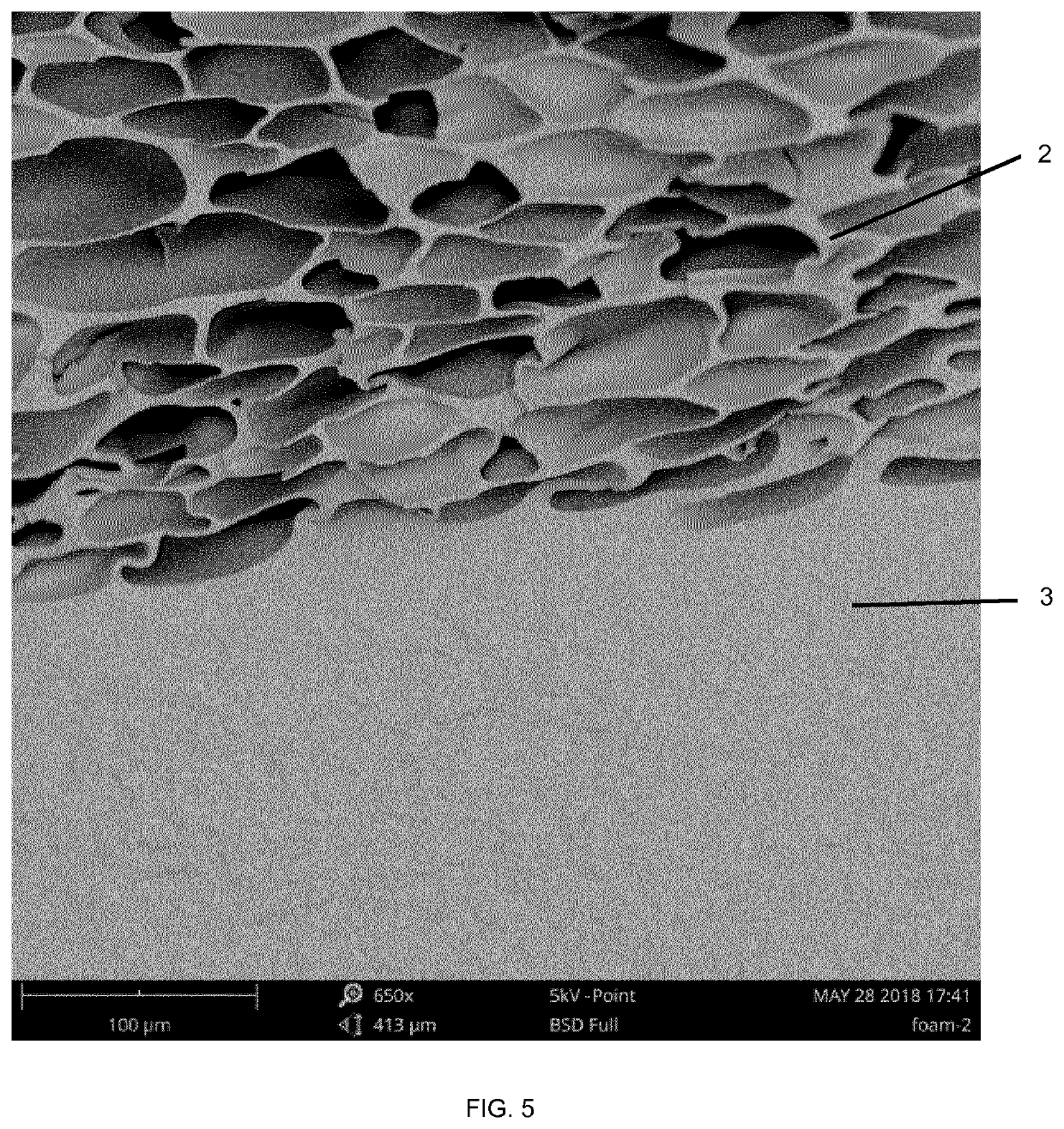

[0073]Example 1 describes the connection of a thermoplastic body using a hot melt adhesive. In order to assess whether a hot melt adhesive could be used to adhere a first body to a thermoplastic body, two thermoplastic bodies were chosen, in this case foamed thermoplastic bodies as described in connection with FIG. 2. The melting temperature TM of these bodies is 160° C. (determined with ASTM D3418-03 as described in this patent application). In a first attempt, a polyester hot melt adhesive having a melting enthalpy of 27±3 J / g was used (the determination of which is based on ASTM standard D3418 using a Mettler STARe differential scanning calorimeter), showing a first order transition temperature (solid to liquid) around 110° C. The hot melt was heated to a temperature of 180° C., thus well above its melting temperature and at a level that is common for using this hot melt to obtain strong connections. The thermoplastic bodies were preheated to various temperatures, ranging from 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting enthalpy | aaaaa | aaaaa |

| melting enthalpy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com