High-density powdered detergent composition

a detergent composition and high-density technology, applied in detergent powders/flakes/sheets, detergent compounding agents, dry-cleaning apparatuses for textiles, etc., can solve problems such as water insolubles, accompanied by formulation restrictions, and problems such as solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

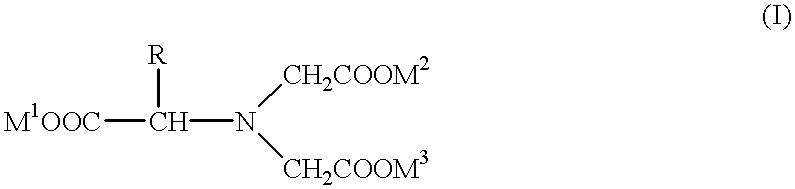

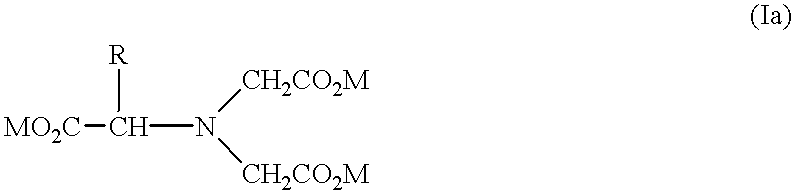

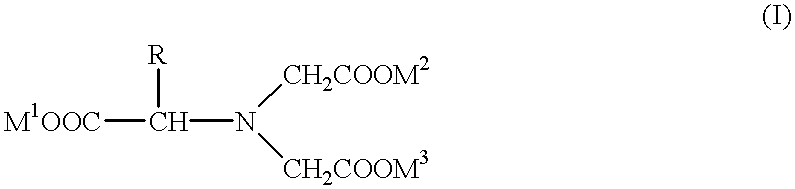

Method used

Image

Examples

example 1

Composition 1 specified in Table 1 was prepared according to the following procedure.

An aqueous slurry having a solid content of 60% by weight was prepared by using 0.5 kg of MGDA, 1.0 kg of crystalline aluminosilicate, 0.8 kg of FA, 0.3 kg of polysodium acrylate and 1.0 kg of soda ash (sodium carbonate). The obtained slurry was subjected to spray drying. The particles thus obtained were put in a Lodige mixer (mfd. by Matsuzaka Giken K.K.), followed by the addition thereto of 1.0 kg of porous silica, 0.5 kg of crystalline aluminosilicate, 2.0 kg of silicate (II), 0.1 kg of an enzyme, the balance of Glauber's salt and 0.05 kg of a fluorescent dye [i.e., 4,4'-bis(2-sulfostyryl)-biphenyl salt]. The resulting mixture was agitated, while 2.0 kg of AE-1 and 0.1 kg of PEG which had been preheated to 70.degree. C. were gradually dropped into the mixture. Thus, the mixture was granulated. Then, 0.5 kg of crystalline aluminosilicate was added to the granulated mixture, and the obtained mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com