Method of epitaxial-like wafer bonding at low temperature and bonded structure

a technology of epitaxial-like wafers and low temperature, applied in the direction of electrical equipment, semiconductor devices, semiconductor/solid-state device details, etc., can solve the problems of large density of threading dislocations in the bulk of the layers, severe and often damaging thermal stresses, and unwanted changes in the bonding material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

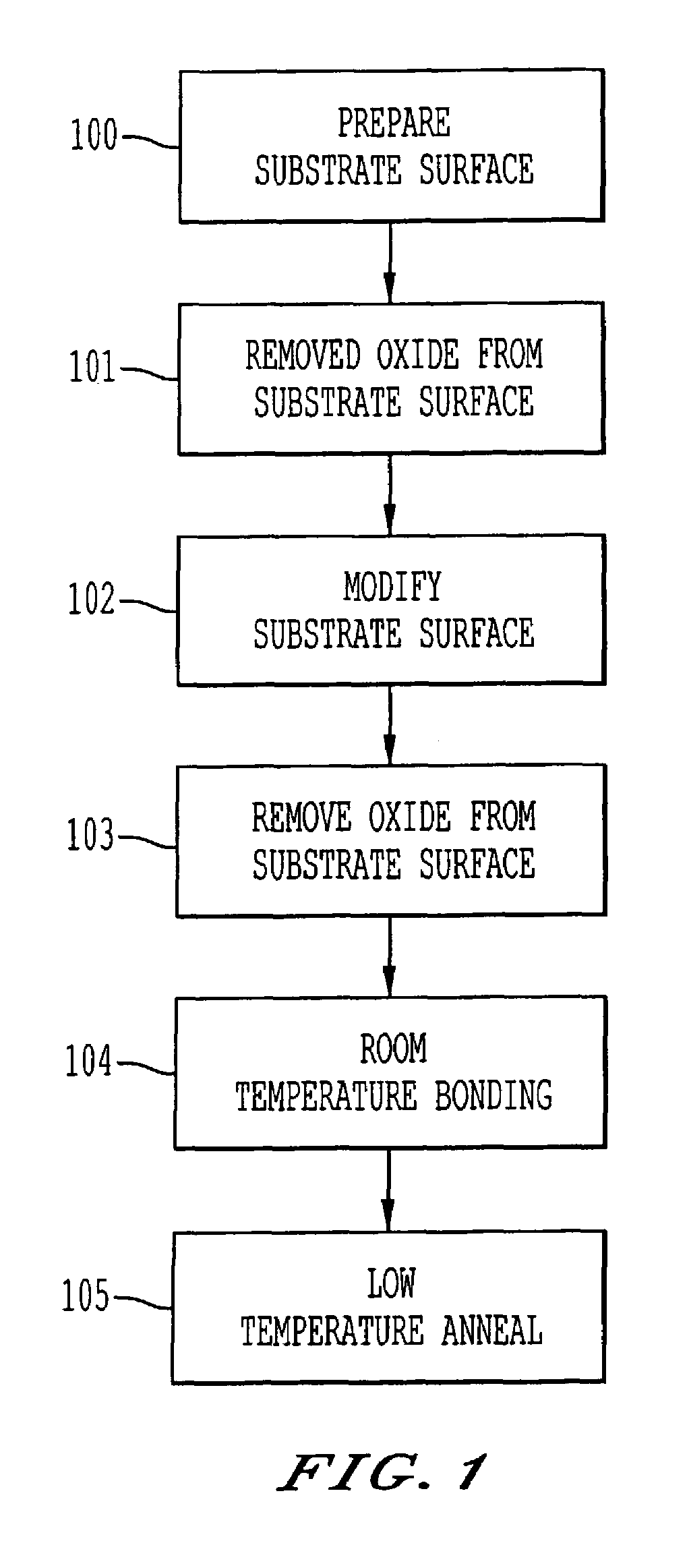

Method used

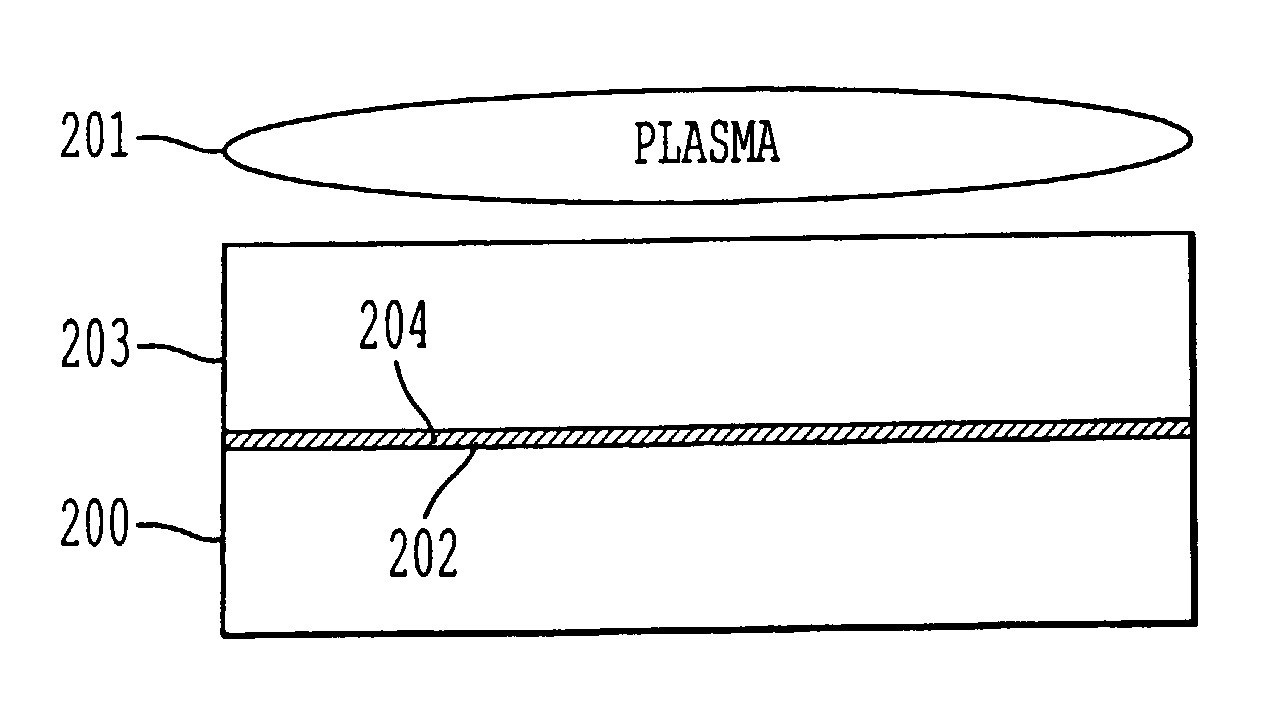

Image

Examples

example

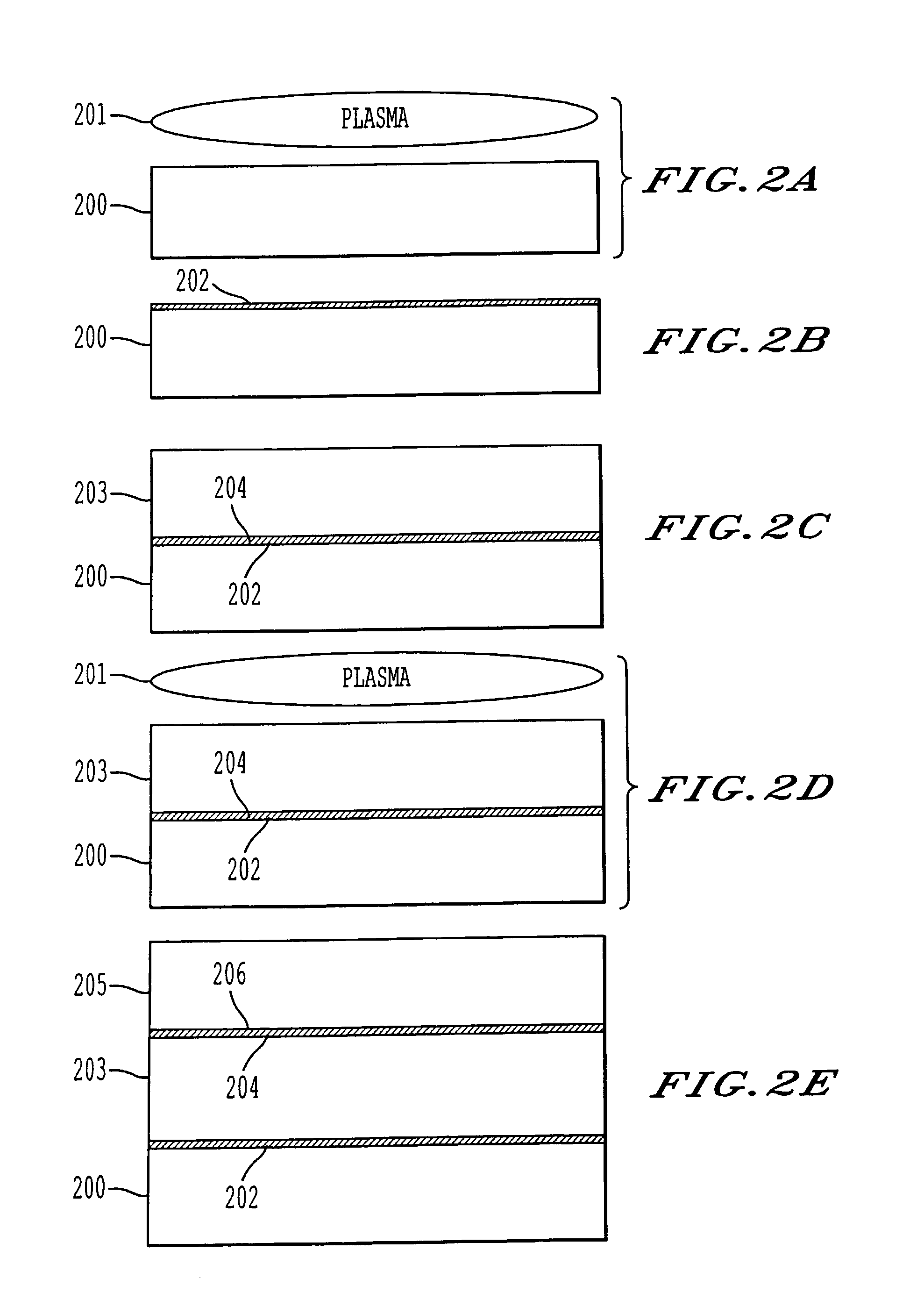

[0056]75 mm diameter, 1-10 ohm-cm, p-type Si (100) substrate wafers were used. The wafers were cleaned in a RCA-1 solution, dipped in a 1% hydrofluoric aqueous solution followed by treatment in B2H6 plasma for an appropriate time period depending on the plasma system used. Appropriate plasma treatment times have ranged from 30 sec. to 5 min. The B2H6 plasma treatment consisted of a mixed gas of 20 sccm of 0.5% B2H6 / 99.5% He and 20 sccm Ar in an inductor coupled plasma (ICP) operating in a reactive ion etch mode with a RF power of 38 W at a pressure of ˜5 mTorr. A ˜100 V self-biased voltage was generated. This self-bias is the lowest possible self-bias for a stable plasma treatment in the plasma treatment system used herein. The wafers were then dipped in a diluted 1% HF solution to remove any oxide on the wafer surfaces. The wafers were then placed together without water rinse and bonded in air at room temperature.

[0057]The bonded wafer pair was stored in a low vacuum chamber at a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com