Patents

Literature

31results about How to "Good cationization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

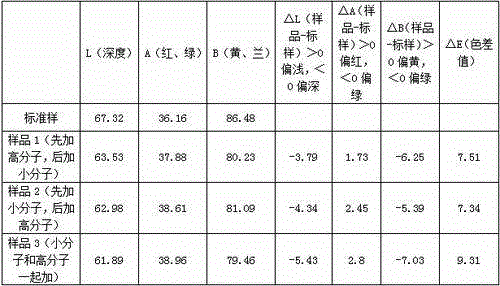

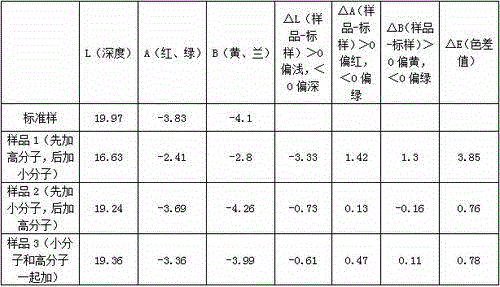

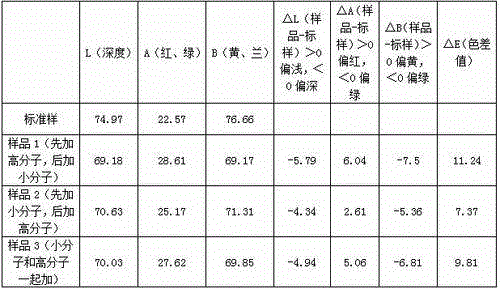

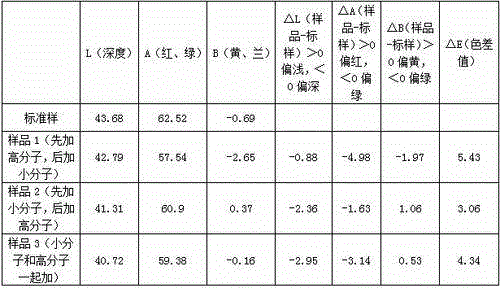

Salt-free low-alkali dyeing process for cellulosic fibers

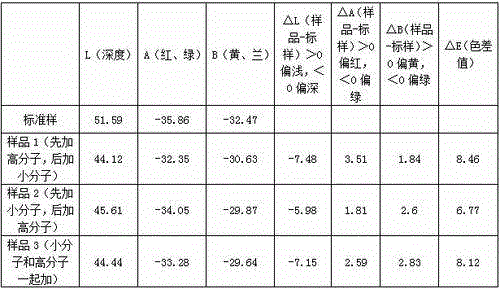

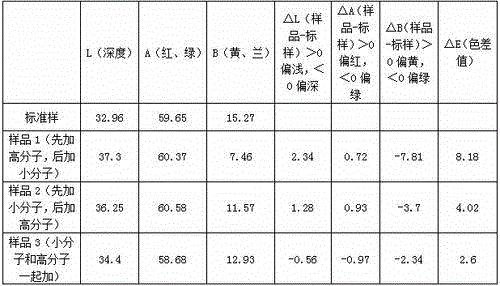

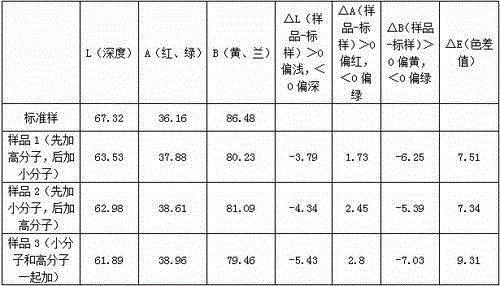

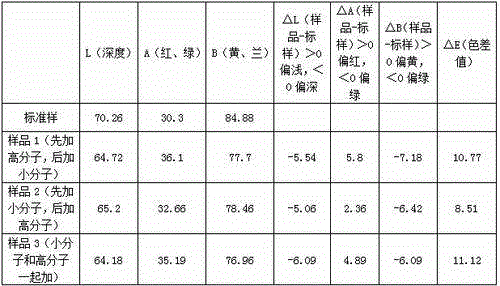

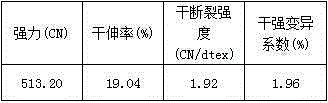

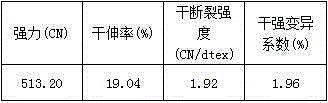

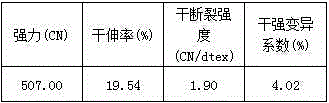

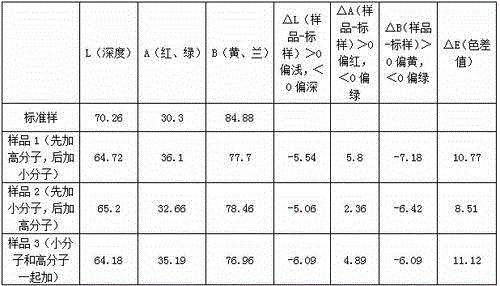

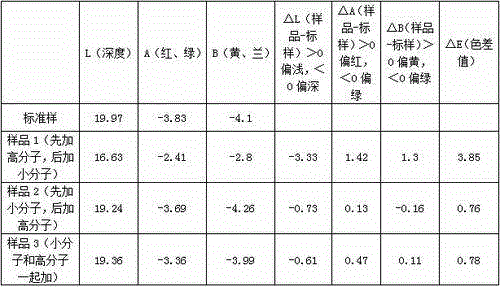

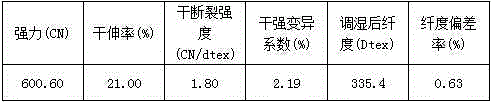

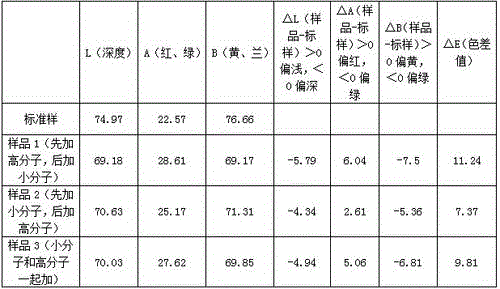

The invention relates to a salt-free low-alkali dyeing process for cellulosic fibers and belongs to the technical field of textile dyeing. The salt-free low-alkali dyeing process comprises the steps of modification treatment, water processing, dyeing and aftertreatment of the cellulosic fibers, wherein in the modification treatment of the cellulosic fibers, a micromolecule quaternary ammonium salt cationic modifier and a macromolecule quaternary ammonium salt cationic modifier are adopted for carrying out modification treatment on the cellulosic fibers. According to the salt-free low-alkali dyeing process, two specific modifiers are adopted, and the synergistic effect of the two modifiers is used cooperatively with the specific dyeing step, so that salt-free low-alkali dyeing of the cellulosic fibers is realized in the dyeing process, pollution is reduced and the cost is reduced; moreover, the process is simplified; difficulty is reduced; modifying and dyeing effects are good; and the salt-free low-alkali dyeing process is suitable for industrial mass production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Cellulose fiber cationic modification method

InactiveCN104358153AMeet the requirements of modified treatmentAdequate responseDyeing processEpoxyPolymer science

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

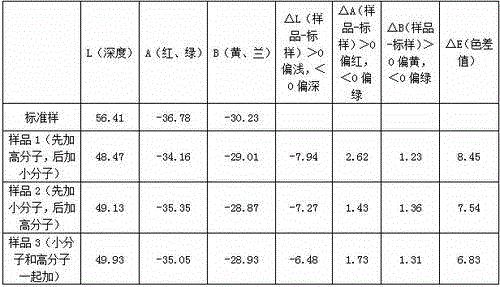

Salt-free low-alkali cellulose fiber circular dyeing process

ActiveCN104358159AIncrease profitEmission reductionDyeing processPulp and paper industryCellulose fiber

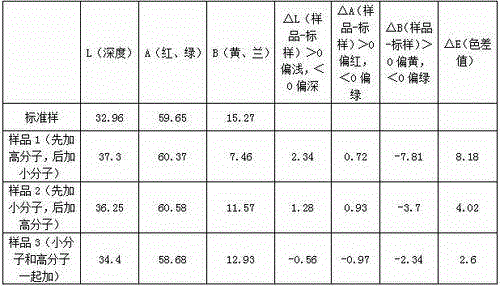

The invention relates to a salt-free low-alkali cellulose fiber circular dyeing process, belonging to the technical field of textile dyeing. The process comprises the steps of cellulose fiber modification treatment, water washing treatment and circular dyeing, wherein in the step of cellulose fiber modification treatment, low molecular quaternary ammonium salt cationic modifiers and high molecular quaternary ammonium salt cationic modifiers are adopted for modification treatment of cellulose fibers. The salt-free low-alkali cellulose fiber circular dyeing process has the beneficial technical effects that two kinds of specific modifiers are adopted, the synergistic effects of the modifiers are given play to and the specific dyeing steps are provided, so that the cellulose fibers achieve salt-free low-alkali dyeing in dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and dyeing effects and are suitable for large-scale industrial production; as the residual dyeing liquid is almost colorless and clear, the residual dyeing liquid can be recycled so as to be continuously used in salt-free dyeing; as the residual dyeing liquid is almost colorless and clear, different colors of dyes can be continuously adopted for circular dyeing.

Owner:北京市文化科技融资租赁股份有限公司

Cationic modified dyeing process for cellulose fiber

InactiveCN104452355AIncrease reaction rateHigh reactivityDyeing processCellulose fiberTextile dyeing

The invention relates to a cationic modified dyeing process for cellulose fiber, and belongs to the technical field of textile dyeing. The cationic modified dyeing process comprises the steps of cellulose fiber modified treatment, water washing treatment, dyeing and aftertreatment, wherein in the cellulose fiber modified treatment, an epoxy quaternary ammonium salt compound and cation starch are adopted to conduct modified treatment on the cellulose fiber. The two specific modifying agents are adopted and play the function of a synergistic effect, and specific dyeing steps are also adopted, so that salt-free low-alkaline dyeing of the cellulose fiber in dyeing is realized, the pollution as well as the cost is reduced, the process is simplified, the difficulty is reduced, the modified and dyeing effects are good, and industrialized mass production is facilitated.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

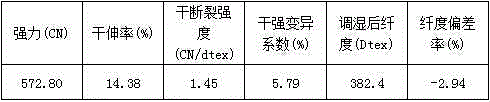

Modification process for cellulosic fibers

The invention relates to a modification process for cellulosic fibers and belongs to the technical field of textile dyeing. The modification process for the cellulosic fibers, which is disclosed by the invention, comprises the following steps: placing the cellulosic fibers into a container; adding water into the container; then carrying out modification treatment on the cellulosic fibers by a small molecule quaternary ammonium salt cationic modifier and a macromolecule quaternary ammonium salt cationic modifier; and after modification treatment, obtaining the modified cellulosic fibers. According to the modification process, two specific modifiers are adopted and the synergistic effect of the two modifiers is used, so that salt-free low-alkali dyeing of the modified cellulosic fibers is realized in the subsequent dyeing process, pollution is reduced and the cost is reduced; moreover, the process is simplified; difficulty is reduced; modifying and subsequent dyeing effects are good; the modification process is suitable for industrial mass production.

Owner:SOUTH CHINA UNIV OF TECH +1

Salt-free low-alkali dyeing method for cellulosic fibers

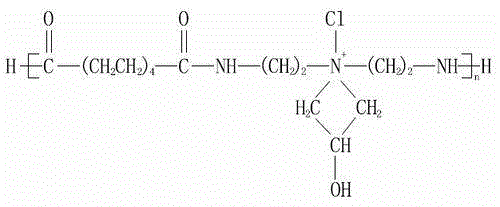

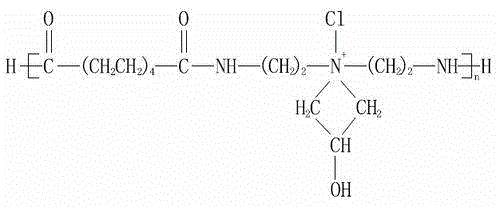

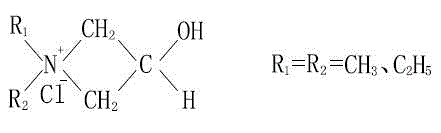

The invention relates to a salt-free low-alkali dyeing method for cellulosic fibers and belongs to the technical field of textile dyeing. The salt-free low-alkali dyeing method comprises the steps of modification treatment, water processing, dyeing and aftertreatment of the cellulosic fibers, wherein in the modification treatment of the cellulosic fibers, 3-acrylamide-2-hydroxypropyltrimonium and polyamide polyamine epichlorohydrin are adopted for carrying out modification treatment on the cellulosic fibers. According to the salt-free low-alkali dyeing method, two specific modifiers are adopted and the synergistic effect of the two modifiers is used cooperatively with the specific dyeing step, so that salt-free low-alkali dyeing of the cellulosic fibers is realized in the dyeing process, pollution is reduced and the cost is reduced; moreover, the process is simplified; difficulty is reduced; modifying and dyeing effects are good; and the salt-free low-alkali dyeing method is suitable for industrial mass production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Salt-free low-alkaline modifying dyeing method of cellulose fiber

PendingCN104404793AIncrease reaction rateHigh reactivityDyeing processProcess engineeringCellulose fiber

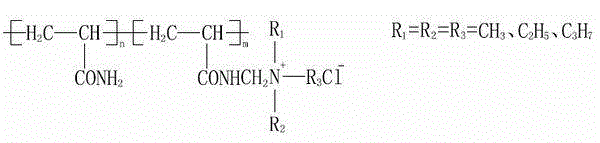

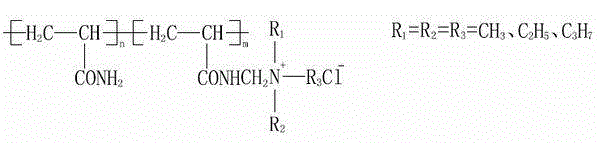

The invention relates to a salt-free low-alkaline modifying dyeing method of a cellulose fiber, and belongs to the technical field of dope dyeing. The method disclosed by the invention comprises the following steps of modified treatment, water processing, dyeing and aftertreatment for the cellulose fiber, wherein the modified treatment for the cellulose fiber adopts an epoxy quaternary ammonium salt compound and a cationic polyacrylamide compound to perform the modified treatment on the cellulose fiber. The method disclosed by the invention adopts two kinds of specific modifying agents, has the function of the synergistic effect of the two agents, and matches with specific dyeing steps, so that the salt-free low-alkaline dyeing for the cellulose fiber is realized in dyeing, pollution is reduced, the cost is saved, the technology is simplified, the difficulty is reduced, and the modifying effect and the dyeing effect are good, so that the method is suitable for the industrial mass production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

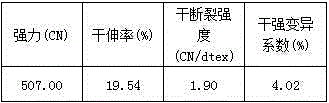

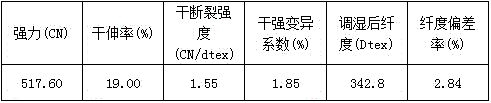

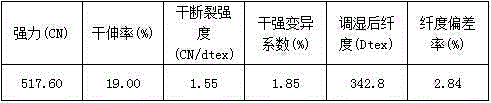

Cationic modified cellulose fibers

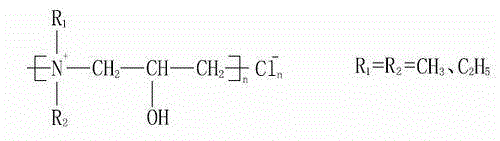

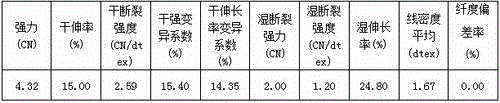

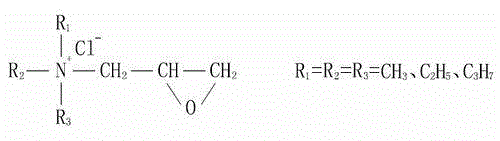

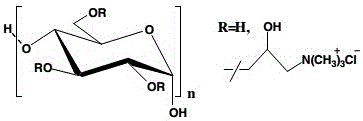

The invention relates to cationic modified cellulose fibers, belonging to the technical field of textile dyeing. The modified cellulose fibers are obtained by carrying out modification treatment on cellulose fibers with a low molecular quaternary ammonium salt cationic modifier and a high molecular quaternary ammonium salt cationic modifier as cationic modifiers and have Zeta electrode potential values of minus 5-15mV when the pH values are 6.5-8.5, wherein the low molecular quaternary ammonium salt cationic modifier is 3-acrylamide-2-hydroxypropyl trimethylammonium chloride; the high molecular quaternary ammonium salt cationic modifier is polyamide polyamine epichlorohydrin. The modified cellulose fibers have the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:YIBIN SPARK NEW FIBER CO LTD

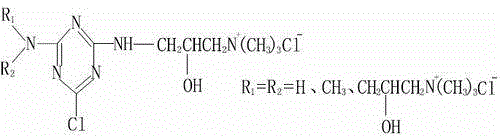

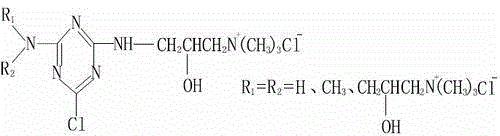

Modified cellulose fibers obtained through modification with modifiers

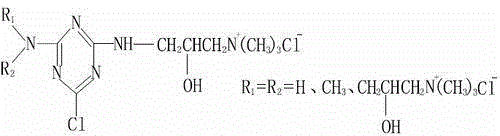

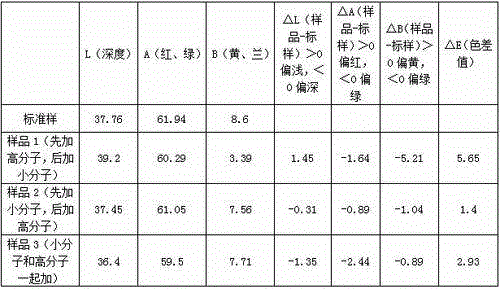

InactiveCN104358166AFully modifiedUniform modificationDyeing processDimethylaminesModified cellulose

The invention relates to modified cellulose fibers obtained through modification with modifiers, belonging to the technical field of textile dyeing. The modified cellulose fibers are obtained by carrying out modification treatment on cellulose fibers with low molecular quaternary ammonium salt cationic modifiers and a high molecular quaternary ammonium salt cationic modifier as cationic modifiers and have Zeta electrode potential values of 0-15mV when the pH values are 6.5-8.5, wherein the low molecular quaternary ammonium salt cationic modifiers are chlorotriazine quaternary ammonium salt compounds; the high molecular quaternary ammonium salt cationic modifier is polyepichlorohydrin dimethylamine. The modified cellulose fibers have the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:YIBIN SPARK NEW FIBER CO LTD

Modified cellulose fibers

PendingCN104358152AHigh degree of cationicImprove permeabilityDyeing processCellulose fiberTextile dyeing

The invention relates to modified cellulose fibers, belonging to the technical field of textile dyeing. The modified cellulose fibers are obtained by carrying out modification treatment on cellulose fibers with two kinds of quaternary ammonium salt cationic modifiers, namely modifiers A and modifiers B, as cationic modifiers and have Zeta electrode potential values of minus 10-30mV when the pH values are 6.5-8.5, wherein the modifiers A are low molecular quaternary ammonium salt cationic modifiers; the modifiers B are high molecular quaternary ammonium salt cationic modifiers. The modified cellulose fibers have the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Cationic modified cellulose fibers

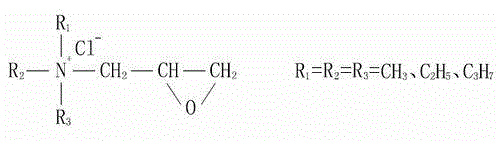

The invention relates to cationic modified cellulose fibers, belonging to the technical field of textile dyeing. The modified cellulose fibers are obtained by carrying out modification treatment on cellulose fibers with a low molecular quaternary ammonium salt cationic modifier and a high molecular quaternary ammonium salt cationic modifier as cationic modifiers and have Zeta electrode potential values of 0-20mV when the pH values are 6.5-8.5, wherein the low molecular quaternary ammonium salt cationic modifier is an azetidine cationic compound; the high molecular quaternary ammonium salt cationic modifier is polyamide polyamine epichlorohydrin. The cationic modified cellulose fibers have the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

Cellulose fiber modification method

The invention relates to a cellulose fiber modification method, belonging to the technical field of textile dyeing. The cellulose fiber modification process comprises the following steps: putting cellulose fibers in a container, then adding water to the container, and then carrying out modification treatment on the cellulose fibers with two kinds of cationic modifiers, namely a low molecular quaternary ammonium salt cationic modifier and a high molecular quaternary ammonium salt cationic modifier, thereby obtaining modified cellulose fibers after modification treatment is completed, wherein the low molecular quaternary ammonium salt cationic modifier is 3-acrylamide-2-hydroxypropyl trimethylammonium chloride; the high molecular quaternary ammonium salt cationic modifier is polyamide polyamine epichlorohydrin. The cellulose fiber modification method has the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Salt-free low-alkali cellulose fiber modified dyeing process

The invention relates to a salt-free low-alkali cellulose fiber modified dyeing process, belonging to the technical field of textile dyeing. The process comprises the steps of cellulose fiber modification treatment, water washing treatment, dyeing and after-treatment, wherein in the step of cellulose fiber modification treatment, epoxy quaternary ammonium salt compounds and branched polyepichlorohydrin dimethylamine are adopted for modification treatment of cellulose fibers. The salt-free low-alkali cellulose fiber modified dyeing process has the beneficial technical effects that two kinds of specific modifiers are adopted, the synergistic effects of the modifiers are given play to and the specific dyeing steps are provided, so that the cellulose fibers achieve salt-free low-alkali dyeing in dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Cellulose fiber cationic modification method

InactiveCN104358162AMeet the requirements of modified treatmentAdequate responseDyeing processEpoxyPolymer science

The invention relates to a cellulose fiber cationic modification method, belonging to the technical field of textile dyeing. The cellulose fiber modification process comprises the following steps: putting cellulose fibers in a container, then adding water to the container, and then carrying out modification treatment on the cellulose fibers with two kinds of cationic modifiers, namely a low molecular quaternary ammonium salt cationic modifier and a high molecular quaternary ammonium salt cationic modifier, thereby obtaining modified cellulose fibers after modification treatment is completed, wherein the low molecular quaternary ammonium salt cationic modifier is an epichlorohydrin parent derivative of epoxy quaternary ammonium salt; the high molecular quaternary ammonium salt cationic modifier is cationic starch. The cellulose fiber cationic modification method has the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Salt-free low-alkali cellulose fiber modified dyeing process

The invention relates to a salt-free low-alkali cellulose fiber modified dyeing process, belonging to the technical field of textile dyeing. The dyeing process comprises the steps of cellulose fiber modification treatment, water washing treatment, dyeing and after-treatment, wherein in the step of cellulose fiber modification treatment, an azetidine cationic compound and polyamide polyamine epichlorohydrin are adopted for modification treatment of cellulose fibers. The salt-free low-alkali cellulose fiber modified dyeing process has the beneficial technical effects that two kinds of specific modifiers are adopted, the synergistic effects of the modifiers are given play to and the specific dyeing steps are provided, so that salt-free low-alkali dyeing of the cellulose fibers is achieved, pollution is reduced, the cost is saved, the process is simplified, the difficulty is reduced, and the modification and dyeing effects are good; therefore the dyeing process is suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Salt-free low-alkali cellulose fiber dyeing method

The invention relates to a salt-free low-alkali cellulose fiber dyeing method, belonging to the technical field of textile dyeing. The dyeing method comprises the steps of cellulose fiber modification treatment, water washing treatment, dyeing and after-treatment, wherein in the step of cellulose fiber modification treatment, 3-acrylamide-2-hydroxypropyl trimethyl ammonium chloride and cationic polyacrylamide compounds are adopted for modification treatment of cellulose fibers. The salt-free low-alkali cellulose fiber dyeing method has the beneficial technical effects that two kinds of specific modifiers are adopted, the synergistic effects of the modifiers are given play to and the specific dyeing steps are provided, so that salt-free low-alkali dyeing of the cellulose fibers is achieved, pollution is reduced, the cost is saved, the process is simplified, the difficulty is reduced, and the modification and dyeing effects are good; therefore the dyeing method is suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Cationization modifying technology of cellulose fiber

The invention relates to a cationization modifying technology of a cellulose fiber, and belongs to the technical field of dope dyeing. The modifying technology of the cellulose fiber disclosed by the invention comprises the following steps: putting the cellulose fiber into a container, adding water to the container, then performing modified treatment on the cellulose fiber by using two kinds of cation modifying agents of a micromolecular quaternary ammonium salt cation modifying agent and a macromolecular quaternary ammonium salt cation modifying agent, and after finishing the modified treatment, obtaining the modified cellulose fiber. The micromolecular quaternary ammonium salt cation modifying agent is an azetidine cation compound, and the macromolecular quaternary ammonium salt cation modifying agent is polyamide polyamine epoxy chloropropane. The method disclosed by the invention adopts two kinds of specific modifying agents and has the function of the synergistic effect of the two agents, so that the salt-free low-alkaline dyeing for the cellulose fiber is realized in the subsequent dyeing, pollution is reduced, the cost is saved, the technology is simplified, the difficulty is reduced, and the modifying effect and the subsequent dyeing effect are good, so that the method is suitable for the industrial mass production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Salt-free low-alkali cellulose fiber modified dyeing method

The invention relates to a salt-free low-alkali cellulose fiber modified dyeing method, belonging to the technical field of textile dyeing. The dyeing method comprises the steps of cellulose fiber modification treatment, water washing treatment, dyeing and after-treatment, wherein in the step of cellulose fiber modification treatment, an epichlorohydrin parent derivative of epoxy quaternary ammonium salt and cationic starch are adopted for modification treatment of cellulose fibers. The salt-free low-alkali cellulose fiber dyeing method has the beneficial technical effects that two kinds of specific modifiers are adopted, the synergistic effects of the modifiers are given play to and the specific dyeing steps are provided, so that salt-free low-alkali dyeing of the cellulose fibers is achieved, pollution is reduced, the cost is saved, the process is simplified, the difficulty is reduced, and the modification and dyeing effects are good; therefore the dyeing method is suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Modified cellulosic fiber

The invention relates to modified cellulosic fiber, and belongs to the technical field of textile dyeing. The modified cellulosic fiber is obtained in the way that cellulosic fiber is subjected to modification treatment by taking a micromolecular quaternary ammonium salt cationic modifier and a macromolecular quaternary ammonium salt cationic modifier as cationic modifiers to obtain the modified cellulosic fiber with the pH value of 6.5-8.5 and the Zeta electrode potential value of 5-26 mV, wherein the micromolecular quaternary ammonium salt cationic modifier is epichlorohydrin parent derivative of epoxy quaternary ammonium salt, and the macromolecular quaternary ammonium salt cationic modifier is the main-chained epicholorohydrin-dimethylamine polymer. According to the invention, the two specific modifiers are adopted, and the role of the synergistic effect of the two specific modifiers is played to enable the modified cellulosic fiber to realize salt-free low-alkaline dyeing in the follow-up dyeing, so that the pollution is reduced, the cost is saved, the process is simplified, the difficulty is reduced, the modification and the follow-up dyeing effect are excellent, and the modified cellulosic fiber is suitable for industrial large-scale production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

Cationic modified cellulose fibers

The invention relates to cationic modified cellulose fibers, belonging to the technical field of textile dyeing. The modified cellulose fibers are obtained by carrying out modification treatment on cellulose fibers with a low molecular quaternary ammonium salt cationic modifier and high molecular quaternary ammonium salt cationic modifiers as cationic modifiers, and have Zeta electrode potential values of minus 8-5mV when the pH values are 6.5-8.5, wherein the low molecular quaternary ammonium salt cationic modifier is 3-acrylamide-2-hydroxypropyl trimethylammonium chloride; the high molecular quaternary ammonium salt cationic modifiers are cationic polyacrylamide compounds. The cationic modified cellulose fibers have the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects and are suitable for large-scale industrial production.

Owner:YIBIN SPARK NEW FIBER CO LTD

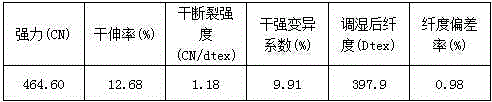

Modified process for cellulose fiber

The invention relates to a modified process for cellulose fiber, and belongs to the technical field of textile dyeing. The modified process comprises the following steps: putting the cellulose fiber into a container, adding water into the container, and then conducting modified treatment on the cellulose fiber with two cation modifying agents of a micromolecule quaternary ammonium salt cation modifying agent and a macromolecule quaternary ammonium salt cation modifying agent, so as to obtain the modified cellulose fiber after the modified treatment, wherein the micromolecule quaternary ammonium salt cation modifying agent is epichlorohydrin parent derivant of epoxy quaternary ammonium salt, and the macromolecule quaternary ammonium salt cation modifying agent is main chain-type epicholorohydrin-dimethylamine polymer. The two specific modifying agents are adopted and play the function of a synergistic effect, so that salt-free low-alkaline dyeing of the modified cellulose fiber in the follow-up dyeing is realized, the pollution as well as the cost is reduced, the process is simplified, the difficulty is reduced, the modified and follow-up dyeing effects are good, and industrialized mass production is facilitated.

Owner:SOUTH CHINA UNIV OF TECH +1

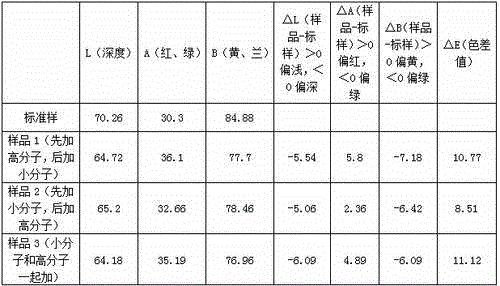

Cellulose fiber dyeing process adopting cationic modification

The invention relates to a cellulose fiber dyeing process adopting cationic modification, belonging to the technical field of textile dyeing. The dyeing process comprises the steps of cellulose fiber modification treatment, water washing treatment, dyeing and after-treatment, wherein in the step of cellulose fiber modification treatment, chlorotriazine quaternary ammonium salt compounds and polyepichlorohydrin dimethylamine are adopted for modification treatment of cellulose fibers. The cellulose fiber dyeing process adopting cationic modification has the beneficial technical effects that two kinds of specific modifiers are adopted, the synergistic effects of the modifiers are given play to and the specific dyeing steps are provided, so that the cellulose fibers achieve salt-free low-alkali dyeing in dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Cellulose fiber modification method

The invention relates to a cellulose fiber modification method, belonging to the technical field of textile dyeing. The cellulose fiber modification process comprises the following steps: putting cellulose fibers in a container, then adding water to the container, and then carrying out modification treatment on the cellulose fibers with two kinds of cationic modifiers, namely a low molecular quaternary ammonium salt cationic modifier and high molecular quaternary ammonium salt cationic modifiers, thereby obtaining modified cellulose fibers after modification treatment is completed, wherein the low molecular quaternary ammonium salt cationic modifier is 3-acrylamide-2-hydroxypropyl trimethylammonium chloride; the high molecular quaternary ammonium salt cationic modifiers are cationic polyacrylamide compounds. The cellulose fiber modification method has the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Salt-free low-alkali cellulose fiber dyeing process

The invention relates to a salt-free low-alkali cellulose fiber dyeing process, belonging to the technical field of textile dyeing. The process comprises the steps of cellulose fiber modification treatment, water washing treatment, dyeing and after-treatment, wherein in the step of cellulose fiber modification treatment, an epichlorohydrin parent derivative of epoxy quaternary ammonium salt and branched polyepichlorohydrin dimethylamine are adopted for modification treatment of cellulose fibers. The salt-free low-alkali cellulose fiber dyeing process has the beneficial technical effects that two kinds of specific modifiers are adopted, the synergistic effects of the modifiers are given play to and the specific dyeing steps are provided, so that the cellulose fibers achieve salt-free low-alkali dyeing in dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Cationic modified cellulose fibers

The invention relates to cationic modified cellulose fibers, belonging to the technical field of textile dyeing. The modified cellulose fibers are obtained by carrying out modification treatment on cellulose fibers with low molecular quaternary ammonium salt cationic modifiers and a high molecular quaternary ammonium salt cationic modifier as cationic modifiers and have Zeta electrode potential values of 10-30mV when the pH values are 6.5-8.5, wherein the low molecular quaternary ammonium salt cationic modifiers are epoxy quaternary ammonium salt compounds; the high molecular quaternary ammonium salt cationic modifier is branched polyepichlorohydrin dimethylamine. The cationic modified cellulose fibers have the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Cellulose fiber cationic modification process

The invention relates to a cellulose fiber cationic modification process, belonging to the technical field of textile dyeing. The cellulose fiber modification process comprises the following steps: putting cellulose fibers in a container, then adding water to the container, and then carrying out modification treatment on the cellulose fibers with two kinds of cationic modifiers, namely low molecular quaternary ammonium salt cationic modifiers and a high molecular quaternary ammonium salt cationic modifier, thereby obtaining modified cellulose fibers after modification treatment is completed, wherein the low molecular quaternary ammonium salt cationic modifiers are epoxy quaternary ammonium salt compounds; the high molecular quaternary ammonium salt cationic modifier is branched polyepichlorohydrin dimethylamine. The cellulose fiber cationic modification process has the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

Modified cellulose fibers obtained through modification

The invention relates to modified cellulose fibers obtained through modification, belonging to the technical field of textile dyeing. The modified cellulose fibers are obtained by carrying out modification treatment on cellulose fibers with low molecular quaternary ammonium salt cationic modifiers and high molecular quaternary ammonium salt cationic modifiers as cationic modifiers and have Zeta electrode potential values of 0-25mV when the pH values are 6.5-8.5, wherein the low molecular quaternary ammonium salt cationic modifiers are epoxy quaternary ammonium salt compounds; the high molecular quaternary ammonium salt cationic modifiers are cationic polyacrylamide compounds. The modified cellulose fibers have the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:YIBIN SPARK NEW FIBER CO LTD

Modified cellulosic fiber obtained through modification of modifier

PendingCN104452354AMeet the requirements of modified treatmentAdequate responseDyeing processCellulose fiberMaterials science

The invention relates to modified cellulosic fiber obtained through modification of a modifier and belongs to the technical field of dope dyeing. The modified cellulosic fiber is prepared from cellulosic fiber through modified treatment by a micromolecule quaternary ammonium salt positive ion modifier and a macromolecule quaternary ammonium salt positive ion modifier as positive ion modifiers; the modified cellulosic fiber has the pH value of 6.5-8.5 and the Zeta electrode potential value of -2-20 mV; the micromolecule quaternary ammonium salt positive ion modifier is an epoxy quaternary ammonium salt compound and the macromolecule quaternary ammonium salt positive ion modifier is cationic starch. According to the invention, the two specific modifiers are adopted to play the synergistic effect, so that salt-free low-alkaline dyeing of the modified cellulosic fiber in the subsequent dyeing can be realized, the pollution is reduced, the cost is decreased, the technology is simplified, the difficulty is lowered, the modified and subsequent dyeing effect is excellent, and the modified cellulosic fiber is applicable to industrialized and large-scale production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

A salt-free and low-alkali cycle dyeing process for cellulose fibers

The invention relates to a salt-free and low-alkali cycle dyeing process for cellulose fibers, which belongs to the technical field of textile dyeing. The present invention includes the steps of cellulose fiber modification treatment, water washing treatment and cycle dyeing, wherein the cellulose fiber modification treatment uses a small molecular quaternary ammonium salt cationic modifier and a high molecular quaternary ammonium salt cationic modifier to modify the cellulose fiber sexual processing. The present invention adopts two specific modifiers to exert the synergistic effect of the two, together with specific dyeing steps, so that the cellulose fibers can be dyed without salt and low alkali, reduce pollution, save costs, and simplify the process , lower difficulty, good modification and dyeing effect, suitable for large-scale industrial production. Because the dyeing residual liquid of the present invention is close to colorless and clear, it can be recycled and continued to be used in the salt-free dyeing of the present invention, and because the dyeing residual liquid is close to colorless and clear, dyes of different colors can be continuously used in cyclic dyeing. Cyclic dyeing.

Owner:北京市文化科技融资租赁股份有限公司

Modified cellulose fiber obtained through modification

The invention relates to a modified cellulose fiber obtained through modification and belongs to the technical field of textile dyeing. The modified cellulose fiber is obtained by modifying a cellulose fiber through cationic modification agents including a small molecular quaternary ammonium salt cationic modification agent and a high molecular quaternary ammonium salt cationic modification agent, and the Zeta electrode potential value of the modified cellulose fiber is 0-15 mV when the pH value is 6.5-8.5; the small molecular quaternary ammonium salt cationic modification agent is an epichlorohydrin matrix derivative of epoxy quaternary ammonium salt, and the high molecular quaternary ammonium salt cationic modification agent is cationic starch. According to the modified cellulose fiber, the two specific modification agents are adopted and have a synergistic effect, so that the modified cellulose fiber can be subjected to salt-free low-alkali dyeing in a subsequent dyeing process, the pollution can be alleviated, the cost can be reduced, the process can be simplified, the difficulty can be lowered, and the modification and subsequent dyeing effects are good; the process is suitable for large-scale industrialized production.

Owner:YIBIN SPARK NEW FIBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com