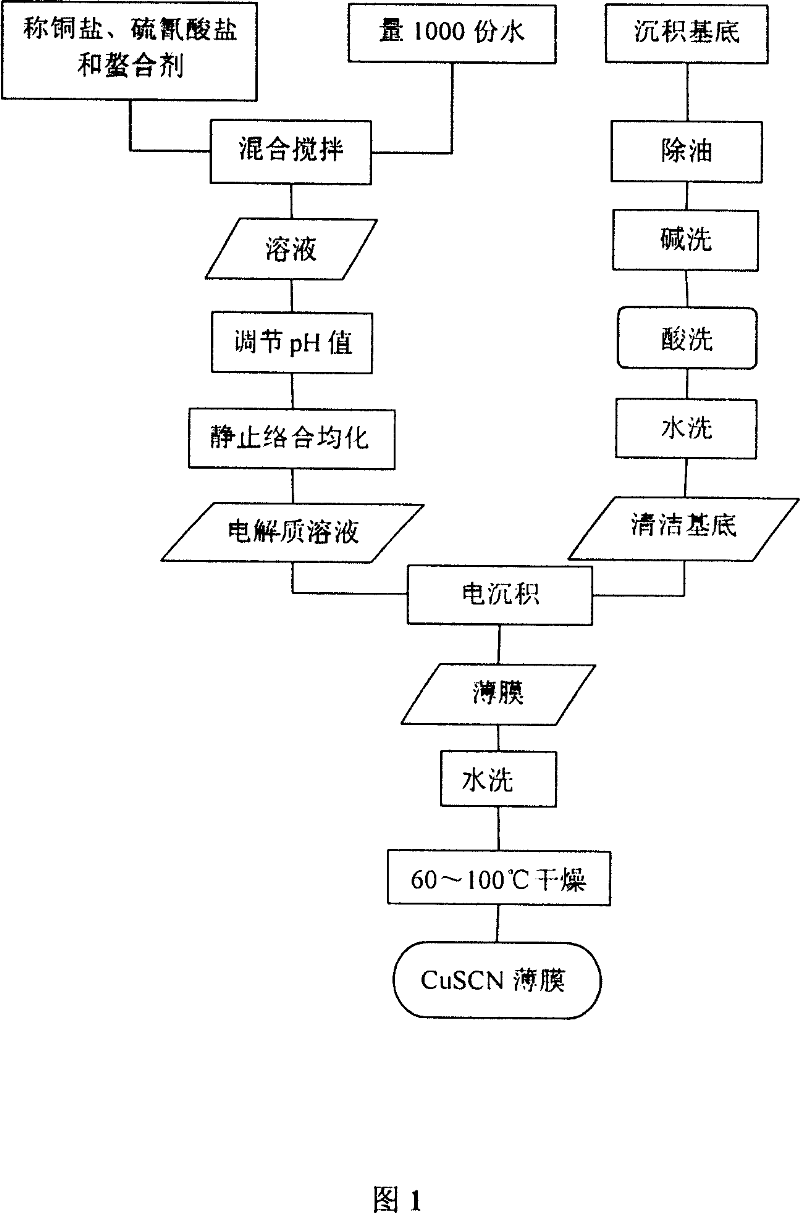

Process for electrodeposition preparation of cuprous sulfocyanide film in aqueous solution

A cuprous thiocyanate and electrodeposition technology, which is applied in circuits, electrical components, and final product manufacturing, etc., can solve the problems of low conductivity, high price, and dye desorption of pure organic electrolytes, and achieves easy control of the production process, The effect of good hole filling and high deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] Weigh 2 parts of Cu(CH3 COO) 2 , 4 parts of disodium ethylenediaminetetraacetic acid (EDTA), 1 part of KSCN, where Cu(CH 3 COO) 2 / EDTA=0.5, Cu(CH 3 COO) 2 / KCN=2.0: Dissolve the three substances weighed in 1000 parts of deionized aqueous solution, and then adjust the pH value to 2.1; the prepared solution is ready for use after 4 hours of static complexation and homogenization. Before deposition, ethanol, 0.1M NaOH and deionized water were used to 2 o 3 -SnO 2 Conductive glass (ITO) is cleaned and dried for use. A platinum sheet was used as an auxiliary electrode, a saturated Ag / AgCl electrode was used as a reference electrode, the temperature of the solution was lowered to 15°C, and the CuSCN film was obtained by depositing at -0.6V (relative to the saturated Ag / AgCl electrode) for 5 minutes. The deposited CuSCN film was rinsed with deionized water, dried at 90°C in vacuum and then tested. It was found that the electrodeposited CuSCN film had a thickness of ab...

example 2

[0039] Weigh 25 parts of CuSO 4 ·5H 2 O, 11 parts of oxalic acid, 1.6 parts of NaSCN, where CuSO 4 ·5H 2 O / .oxalic acid=2.3, CuSO 4 ·5H 2 O / NaSCN=15.5: Dissolve the weighed three substances in 1000 parts of deionized aqueous solution respectively, and adjust the pH value to 3; the prepared solution is ready for use after 24 hours of static complexation and homogenization. Before deposition, ethanol, 0.1M NaOH and deionized water were used to 2 o 3 -SnO 2 Conductive glass (ITO) is cleaned and dried for use. A platinum sheet was used as an auxiliary electrode, a saturated Ag / AgCl electrode was used as a reference electrode, the temperature of the solution was controlled at 35°C, and a CuSCN film was deposited at -0.6V (relative to the saturated Ag / AgCl electrode) for 10 minutes. The deposited CuSCN film was rinsed with deionized water, dried at 90°C in vacuum and then tested. It was found that the electrodeposited CuSCN film had a thickness of about 2 μm, a crystal grai...

example 3

[0041] Weigh 12.5 parts of CuSO respectively 4 ·5H 2 O, 10.5 parts of citric acid, 2.4 parts of KSCN, wherein CuSO 4 ·5H 2 O / oxalic acid = 1.2, CuSO 4 ·5H 2 O / KSCN=5.2: Dissolve the weighed three substances in 1000 parts of deionized aqueous solution respectively, and adjust the pH value to 4.6: The prepared solution is ready for use after 24 hours of static complexation and homogenization. Before deposition, ethanol, 0.1M NaOH and deionized water were used to 2 o 3 -SnO 2 Conductive glass (ITO) is cleaned and dried for use. A platinum sheet was used as an auxiliary electrode, a saturated Ag / AgCl electrode was used as a reference electrode, the temperature of the solution was controlled at 25°C, and a CuSCN film was deposited at -0.5V (relative to the saturated Ag / AgCl electrode) for 10 minutes. The deposited CuSCN film was rinsed with deionized water, dried at 90°C in vacuum and then tested. It is found that the electrodeposited CuSCN film has a thickness of about 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com