Nanometer phosphate ferrolithium/carbon composite materials, production of solid-phase and use thereof

A lithium iron phosphate and carbon composite material technology, applied in the directions of phosphates, phosphorus oxyacids, lithium compounds, etc., can solve the problems of large product particles and high process costs, and achieve a simplified preparation process, excellent rate performance, and good electrical properties. Effects of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

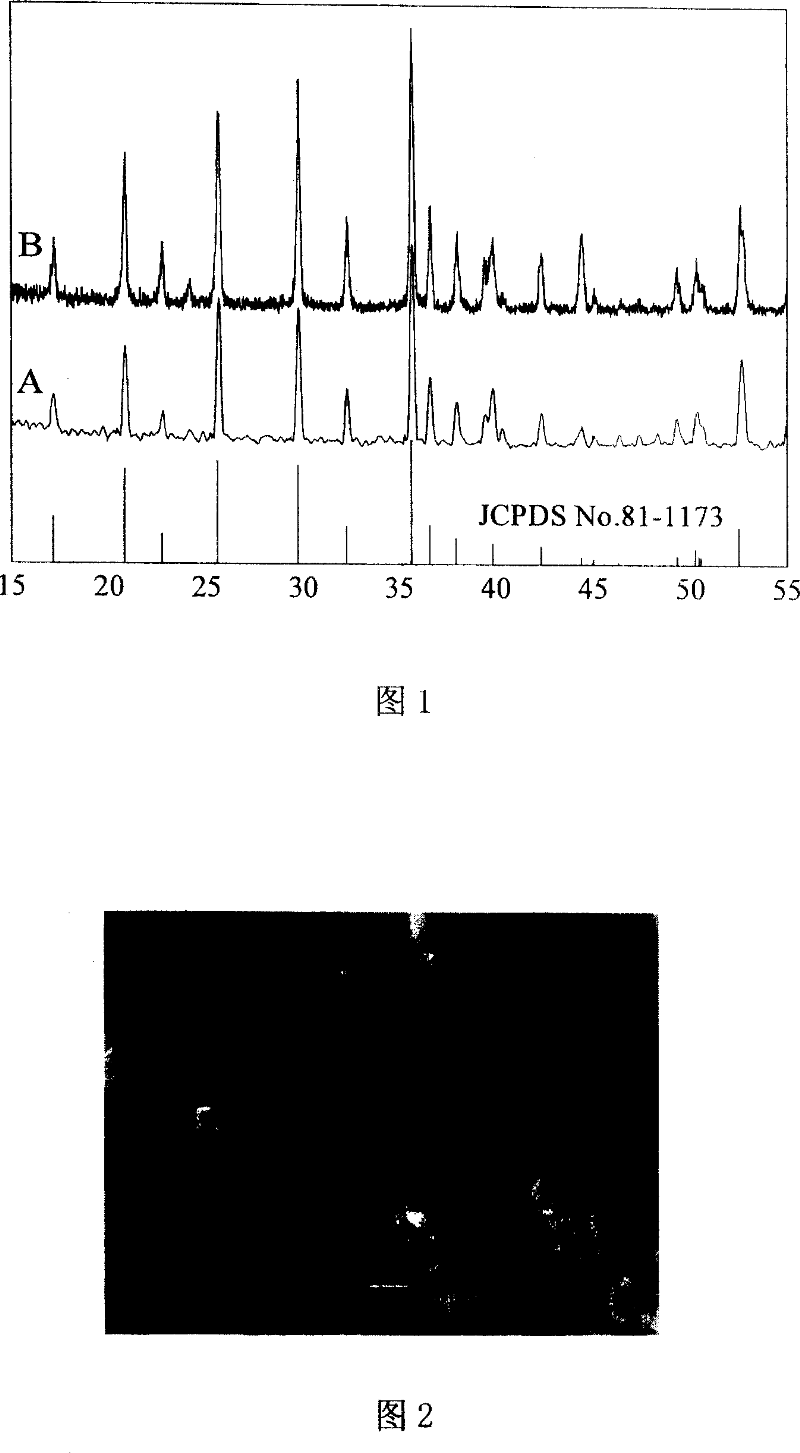

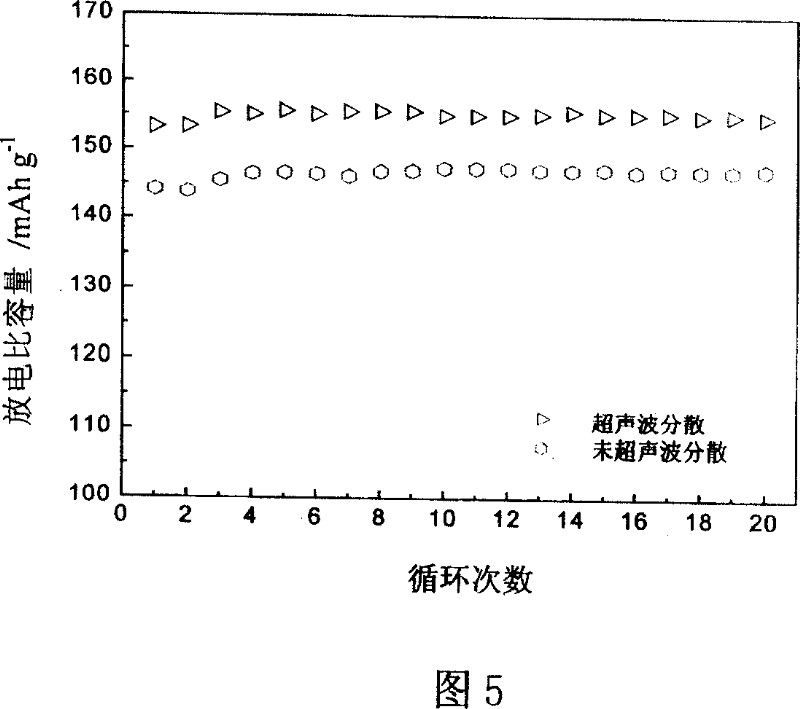

[0037] Chemically pure FeC 2 o 4 ·H 2 O, NH 4 h 2 PO 4 , LiOH·H 2 O is the raw material, according to the proportion of 1:1:1 ingredients, first LiOH·H 2 O and NH 4 h 2 PO 4 Mix for 2 hours before adding FeC 2 o 4 ·H 2 After O was mixed for 2 hours, β-cyclodextrin was added, and β-cyclodextrin was used as the carbon source precursor, and the amount added was to decompose β-cyclodextrin with a carbon content of 5 wt%. Ball mill mixing time 4h. The homogeneously mixed slurry was dried under natural conditions for 5 hours until the ethanol volatilized completely. The dried slurry is treated in a program-controlled horizontal furnace with a two-stage high-temperature solid-phase method, and inert gas protection is always used during the treatment process. The heating rate is 5°C / min. First, the temperature is raised to 300°C, and the temperature is kept for 6 hours; it is taken out and ground for 2 hours, and then placed in a horizontal furnace, the temperature is ra...

Embodiment 2

[0041] Chemically pure FeC 2 o 4 ·H 2 O, NH 4 h 2 PO 4 , LiOH·H 2 O is the raw material, and it is mixed evenly in a ball mill tank at a ratio of 1:1:1, and cyclodextrin with a decomposed carbon content of 5 wt% is added as a carbon source precursor, and the ball milling time is 4 hours. The uniformly mixed slurry was dispersed under 50KHz ultrasonic frequency for 6 hours; then dried under natural conditions for 5 hours until the ethanol volatilized completely. All the other processing conditions are exactly the same as in Example 1. Obtained LiFePO 4 The discharge specific capacity of the / C composite is 153mAh / g at 0.1C. Its particle size is shown in Figures 2 and 3, and the particle size is 200-500 nm.

Embodiment 3

[0043] Replace ferrous oxalate with ferrous acetate, and use Li 2 CO 3 , mix the raw materials in the ratio of Li:Fe:P 1.05:1:1, use Ar+H 2 (volume ratio 95:5) mixed atmosphere protection. All the other are with embodiment 2. Obtained LiFePO 4 The discharge specific capacity of the / C composite is 146mAh / g at 0.1C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com