High-power nano ball shape lithium cobaltate material and producing method thereof

A technology of spherical lithium cobaltate and nano-lithium cobaltate, which is applied in the field of electrochemistry and lithium battery material science, can solve the problems of material cycle performance degradation, large surface energy of nanoparticles, and small degree of polarization, etc., and increase the capacity retention rate , Avoid particle agglomeration, improve the effect of tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

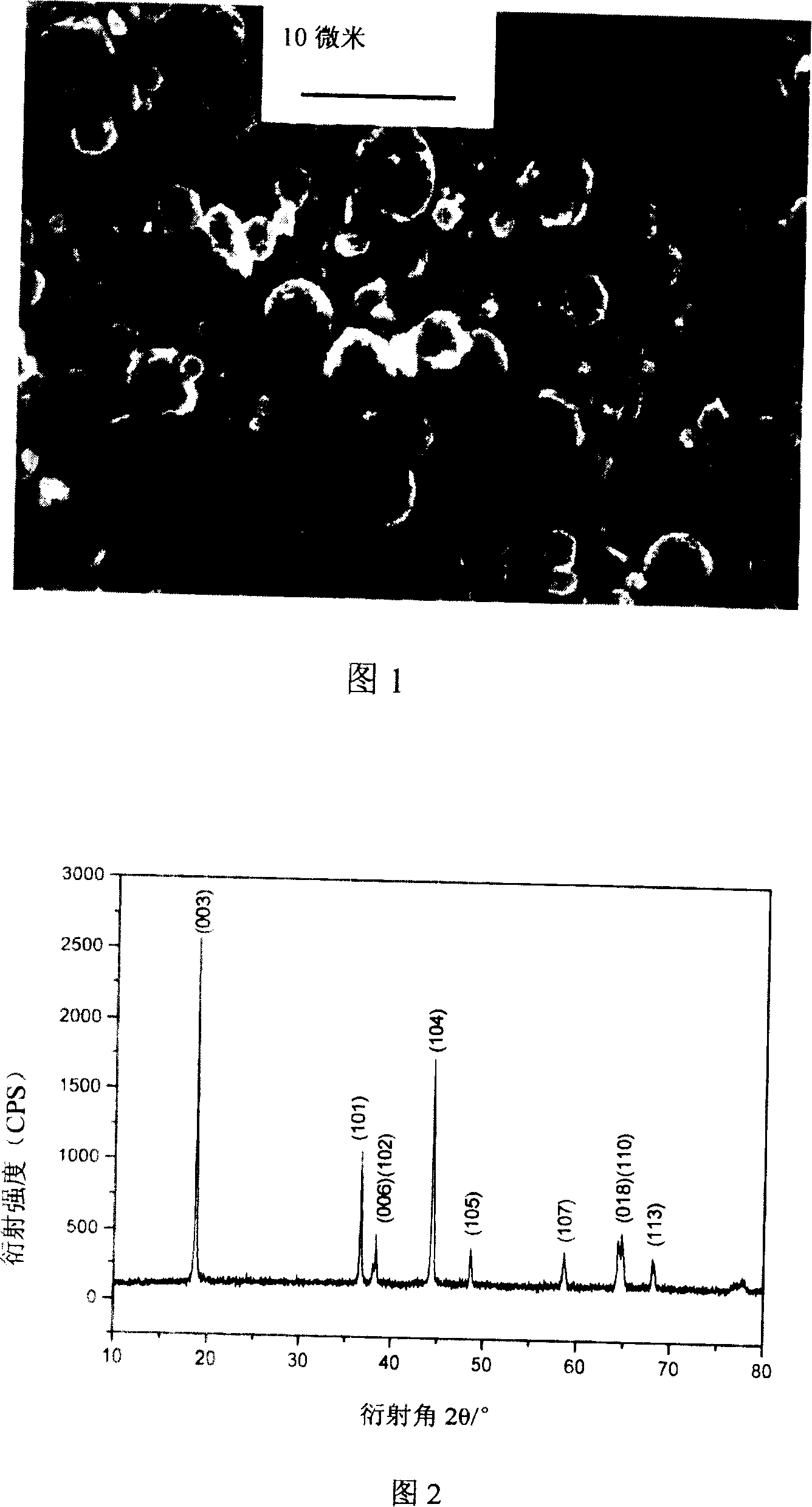

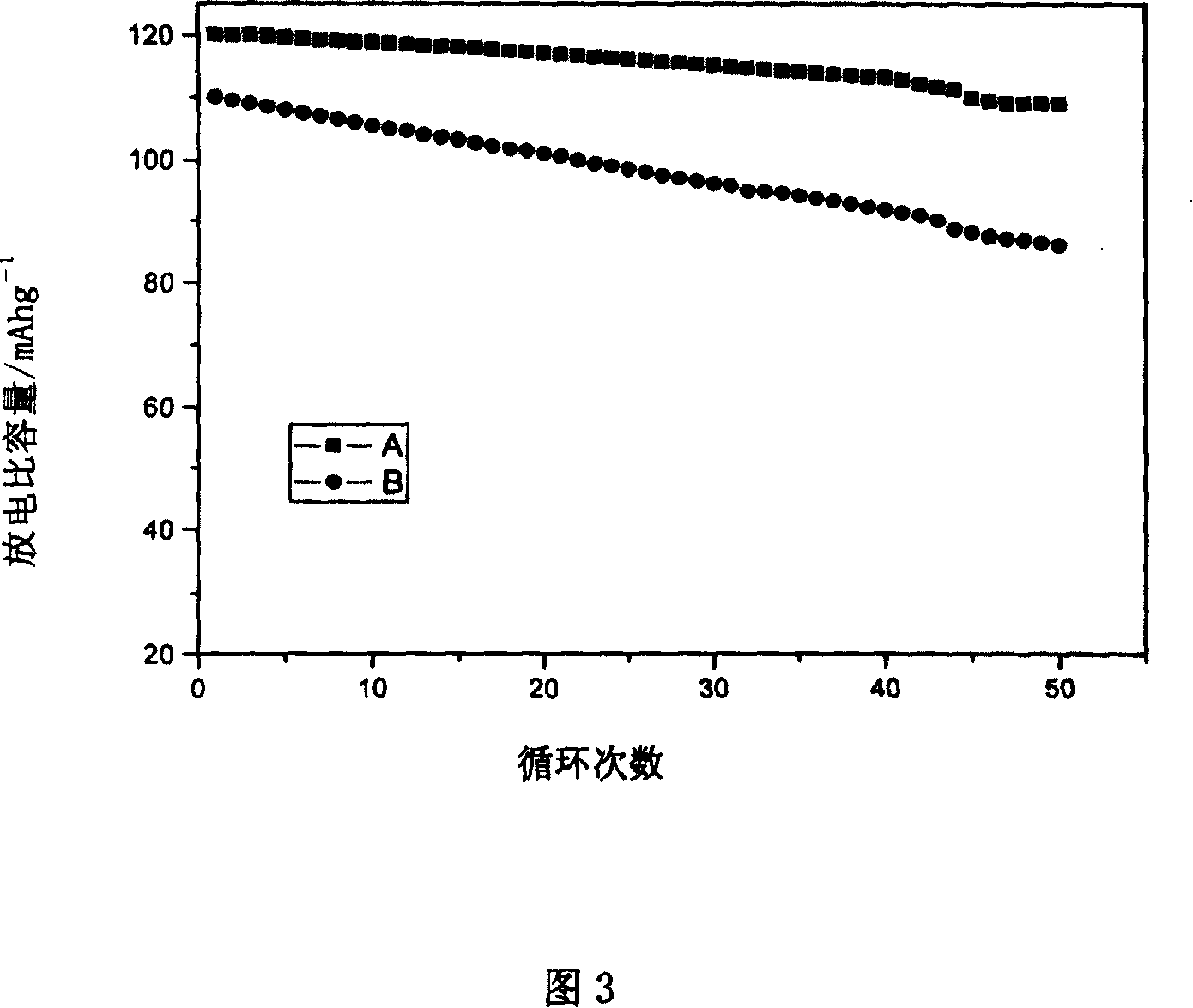

[0016] Mix carbon nanotubes and nano-lithium cobaltate evenly, the diameter of carbon nanotubes is 10-12 nanometers, the tube length is 2-10 microns, the particle size of nano-lithium cobaltate is 100-500 nanometers, and the mass ratio of the two is 1: 100; using deionized water to prepare a methylcellulose solution with a mass concentration of 2%. The carbon nanotubes and nano-lithium cobaltate were uniformly dispersed in the above methyl cellulose solution at a concentration of 0.05 g / mL. Uniformly disperse sorbitan monooleate in liquid paraffin with a mass concentration of 8%. Add the above-mentioned methylcellulose solution containing carbon nanotubes and nano-lithium cobaltate dropwise into the above-mentioned oil phase, emulsify for 0.5 hours, stir at a speed of 700r / min, control the temperature at 30°C, and react for 10 hours; after the reaction, Centrifugal washing with n-hexane and acetone respectively, drying at 80°C for 12 hours, and heat treatment at 250°C for 4 h...

Embodiment 2

[0018] Mix carbon nanotubes and lithium cobaltate nanometers evenly, the diameter of carbon nanotubes is 10-12 nanometers, the tube length is 2-10 microns, the particle size of lithium cobaltate nanometers is 100-500 nanometers, and the mass ratio of the two is 2: 100. A methylcellulose solution was prepared with deionized water at a concentration of 0.8%. The carbon nanotubes and nano-lithium cobaltate were uniformly dispersed in the above methyl cellulose solution at a concentration of 0.16 g / mL. Uniformly disperse sorbitan monooleate in n-heptane at a mass concentration of 5%. Add the above-mentioned methylcellulose solution containing carbon nanotubes and nano-lithium cobaltate dropwise into the above-mentioned oil phase, emulsify for 1 hour, stir at 600 r / min, control the temperature at 35°C, and react for 8 hours; after the reaction , successively washed by centrifugation with n-hexane and acetone, dried at 80°C for 12 hours, and then heat-treated at 220°C for 5 hours ...

Embodiment 3

[0020] Mix carbon nanotubes and lithium cobaltate nanometers evenly, the diameter of carbon nanotubes is 10-12 nanometers, the tube length is 2-10 microns, the particle size of lithium cobaltate nanometers is 100-500 nanometers, and the mass ratio of the two is 3: 100; using deionized water to prepare a methylcellulose solution with a mass concentration of 1.2%; uniformly dispersing carbon nanotubes and nano-lithium cobaltate into the above methylcellulose solution with a concentration of 0.27g / mL. Uniformly disperse sorbitan monooleate in cyclohexane with a mass concentration of 1%. Add the above-mentioned methylcellulose solution containing carbon nanotubes and nano-lithium cobaltate dropwise into the above-mentioned oil phase, emulsify for 2.5 hours, stir at a speed of 800r / min, control the temperature at 25°C, and react for 12 hours; after the reaction, Centrifugal washing with n-hexane and acetone respectively, drying at 80°C for 12 hours, and heat treatment at 200°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com