Method and apparatus for detecting polysilicon gate etching terminal

A detection device and polysilicon technology, applied in the field of microelectronics, can solve the problems of strong sensitivity, difficult to directly control the etching end point, unable to reliably protect the gate oxide layer, etc., to ensure the effect of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

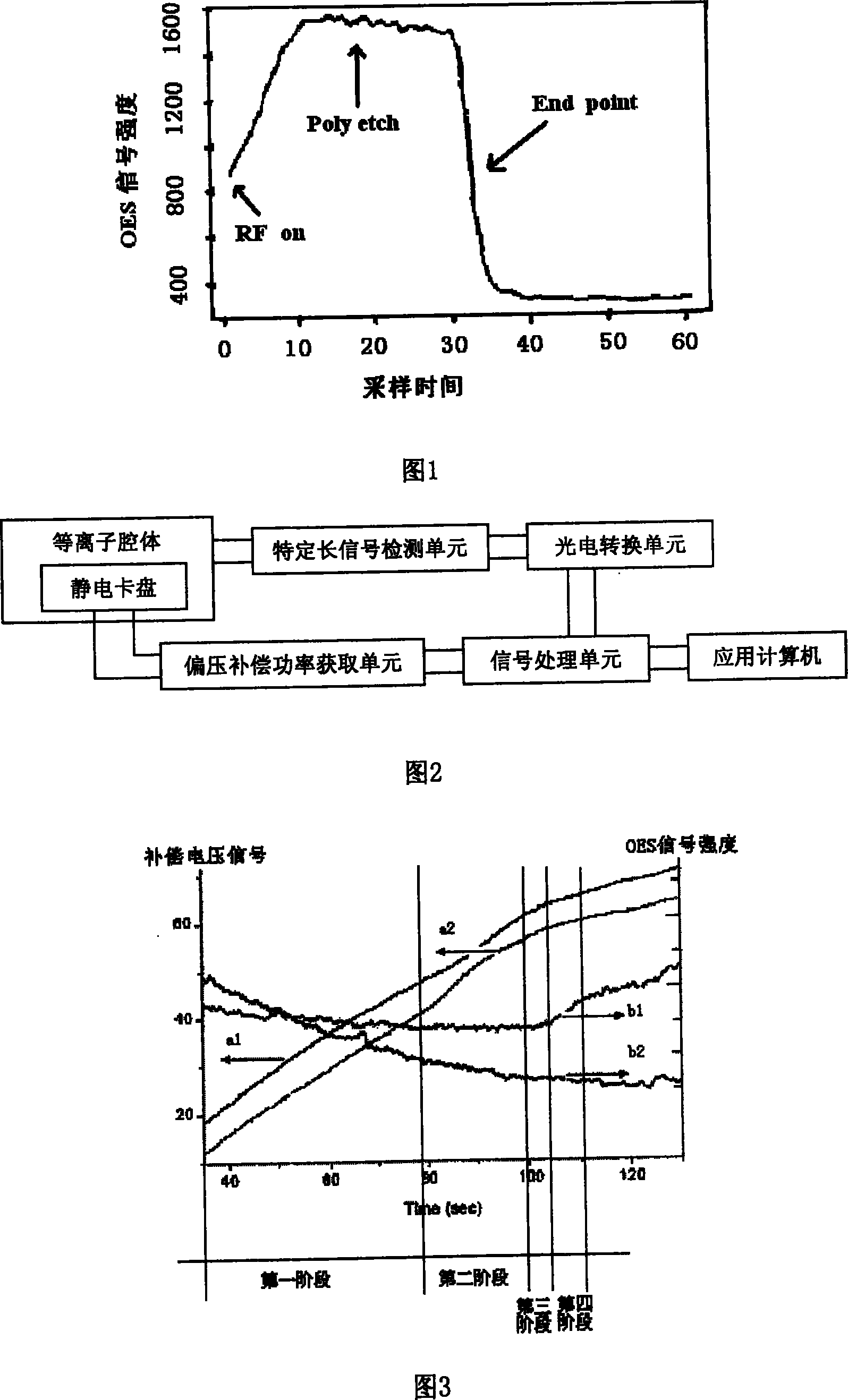

[0024] The device for detecting the end point of polysilicon gate etching according to the present invention has a specific embodiment, as shown in FIG. 2, including several units:

[0025] Bias voltage compensation power acquisition unit: used to acquire the bias voltage compensation power information of the electrostatic chuck, and output it to the signal processing unit;

[0026] Specific wavelength signal detection unit: used to detect specific wavelength signal information in the polysilicon gate etching cavity, and send it to the photoelectric conversion unit; this embodiment adopts a monochromator;

[0027] Photoelectric conversion unit: converts the specific wavelength signal information into an electrical signal and outputs it to the signal processing unit; this embodiment adopts a photomultiplier tube;

[0028] Signal processing unit: filter and amplify the bias voltage compensation power information and the electrical signal corresponding to the specific wavelength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com