Low-temperature solvent heat growth method of cadmium telluride single-crystal

A growth method, cadmium telluride technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of crystal defects, high reaction temperature, complicated experimental operation, etc., achieve air stability, simple preparation process, and raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Put the pre-configured CdCl-containing 2 5mmol, TeO 2 5mmol, NaBH 4 10mmol of 40mL ammonia (25wt.%) mixed solution is charged into a reaction kettle with a polytetrafluoroethylene liner. After sealing, it rises from room temperature to 160°C within 45min, and the reaction stops after 7 days at 160°C. After heating, the single crystal was taken out after being naturally cooled to room temperature, washed with distilled water and absolute ethanol, and then dried in a vacuum oven at 60°C for 3 hours to obtain the product.

Embodiment 2

[0024] CdSO 4 Instead of CdCl in Example 1 2 As a cadmium source, with ammonia (25wt.%) as a solvent, take CdSO 4 , TeO 2 and NaBH 4 The amount of the substance is respectively 5mmol, 5mmol and 10mmol; This mixed solution is packed in the reaction kettle lined with polytetrafluoroethylene, after airtight, at 200 ℃ of constant temperature for 3 days, stop heating, and aftertreatment is identical with embodiment 1 thereafter, get the product.

Embodiment 3

[0026] use Na 2 TeO 3 Instead of TeO in Example 1 2 As a source of tellurium, with ammonia (25wt.%) as a solvent, take Na 2 TeO 3 , CdCl 2 and NaBH 4 The amounts of the substances were 5mmol, 5mmol and 10mmol respectively; the operation steps were the same as in Example 1, the reaction was kept at 180°C for 5 days, and then the heating was stopped. After natural cooling to room temperature, the single crystal was taken out and washed with distilled water and absolute ethanol. , and then dried in a vacuum oven at 60° C. for 3 hours to obtain the product.

[0027] The product was characterized by target X-ray powder diffraction (XRD) and scanning electron microscopy (SEM):

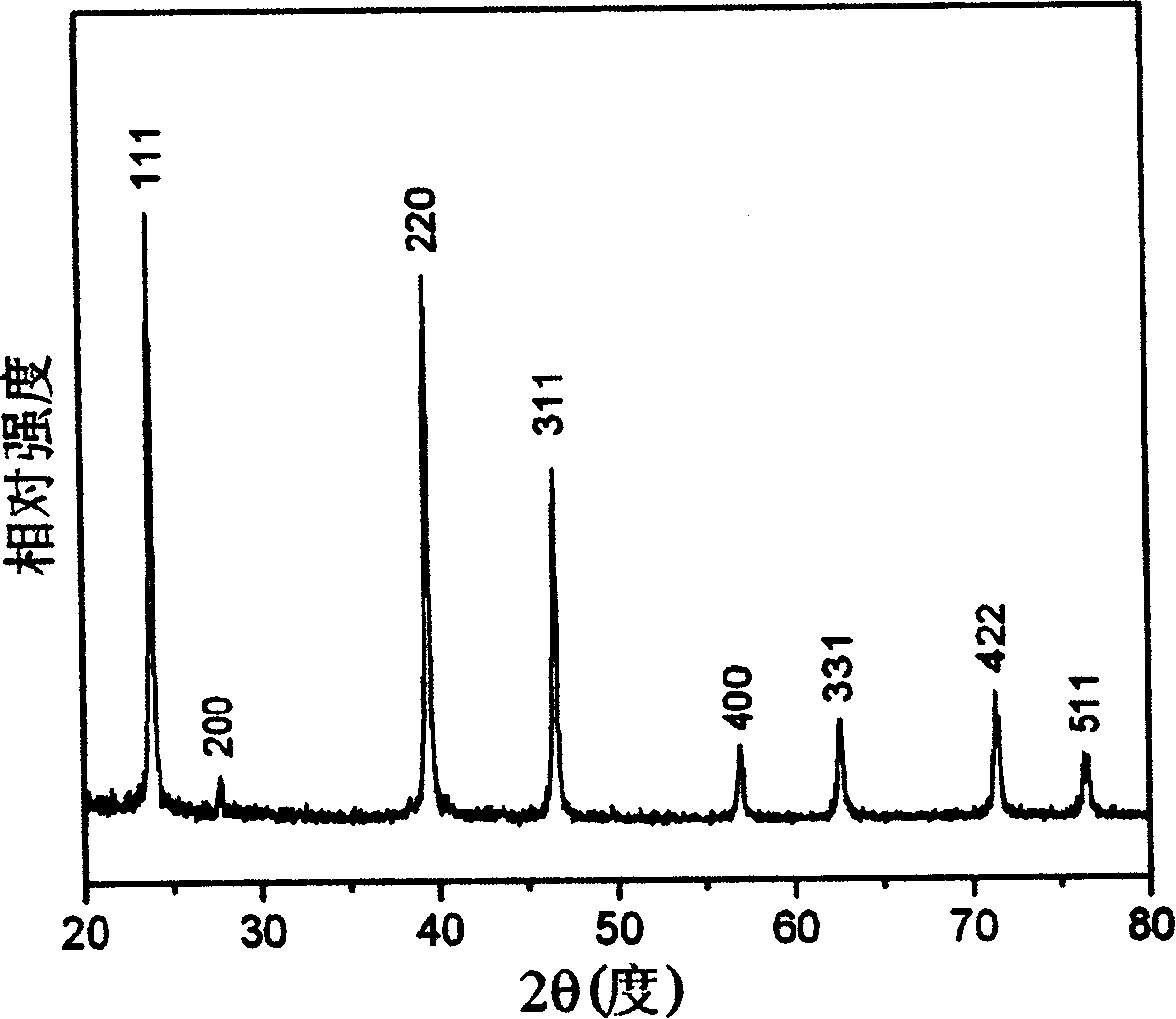

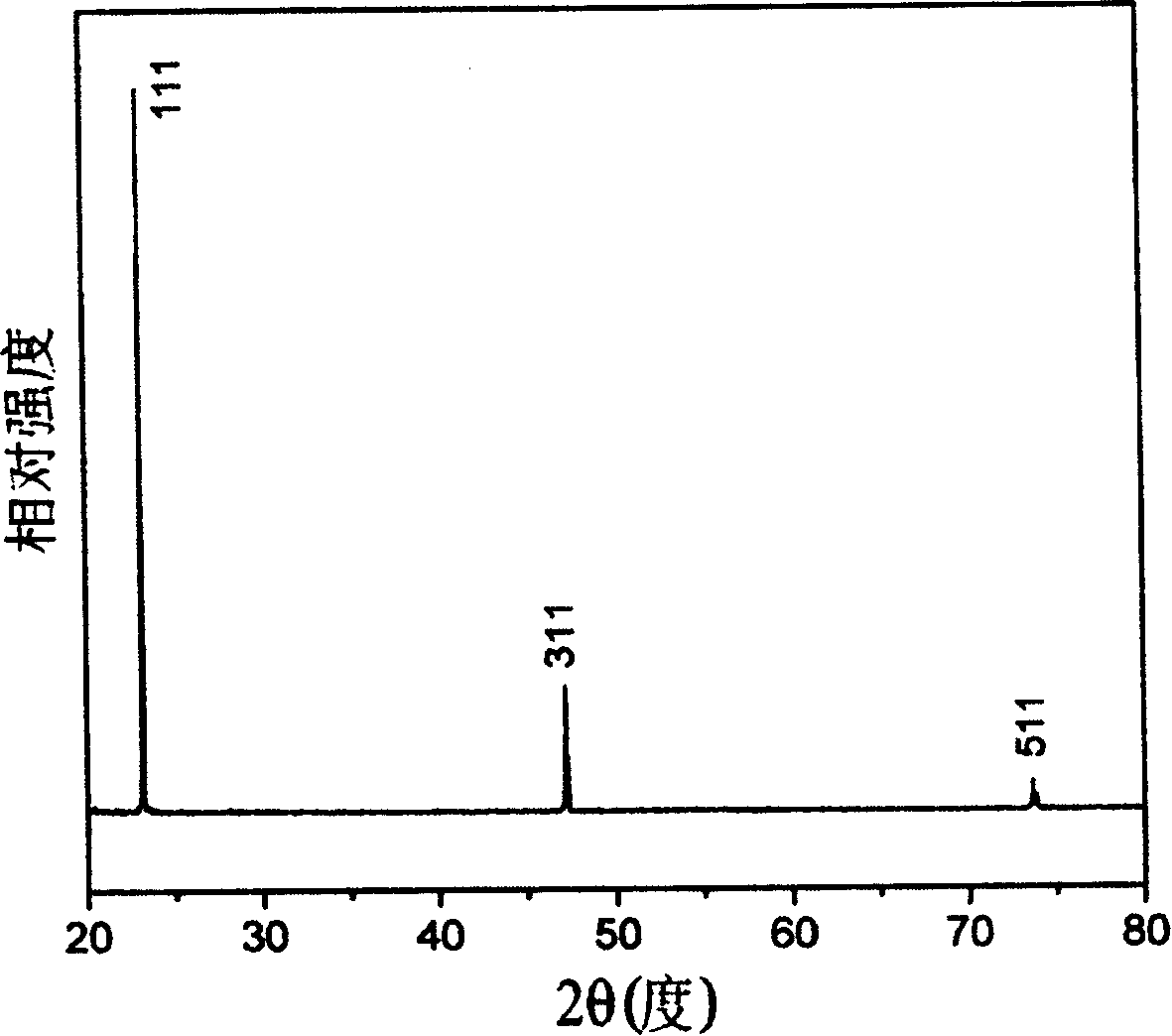

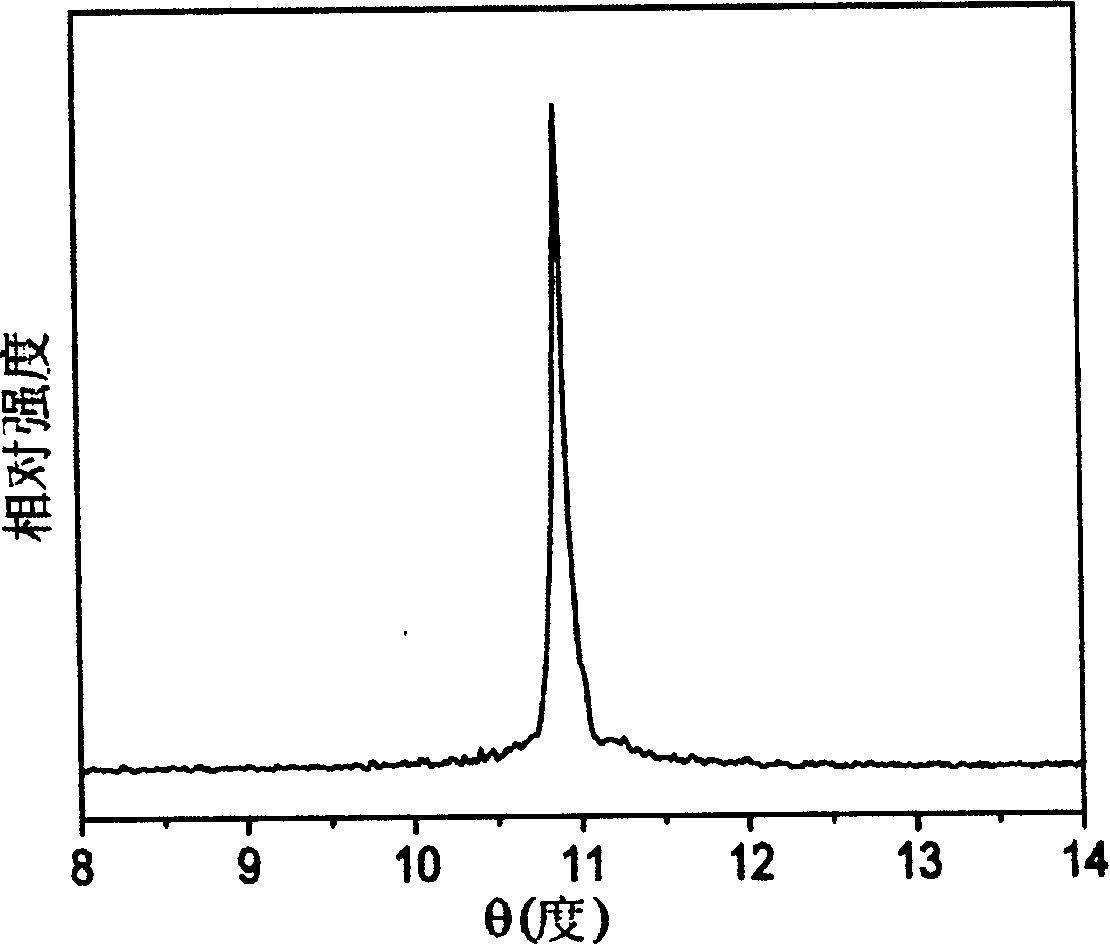

[0028] figure 1 The XRD pattern diagram of the product obtained in the above examples after being ground into powder is given, which shows that each diffraction peak can be indexed to the face-centered cubic phase CdTe, and no diffraction peaks of impurities are found. Based on this calculation, the un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com