Method for preparing Nano composite material of stannic oxide / titanium dioxide

A nanocomposite material and titanium dioxide technology, which is applied in the field of preparation of tin dioxide/titanium dioxide nanocomposite materials, can solve the problems of high composite probability and low photocatalytic efficiency, and achieve the effects of low equipment requirements, high photocatalytic ability and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

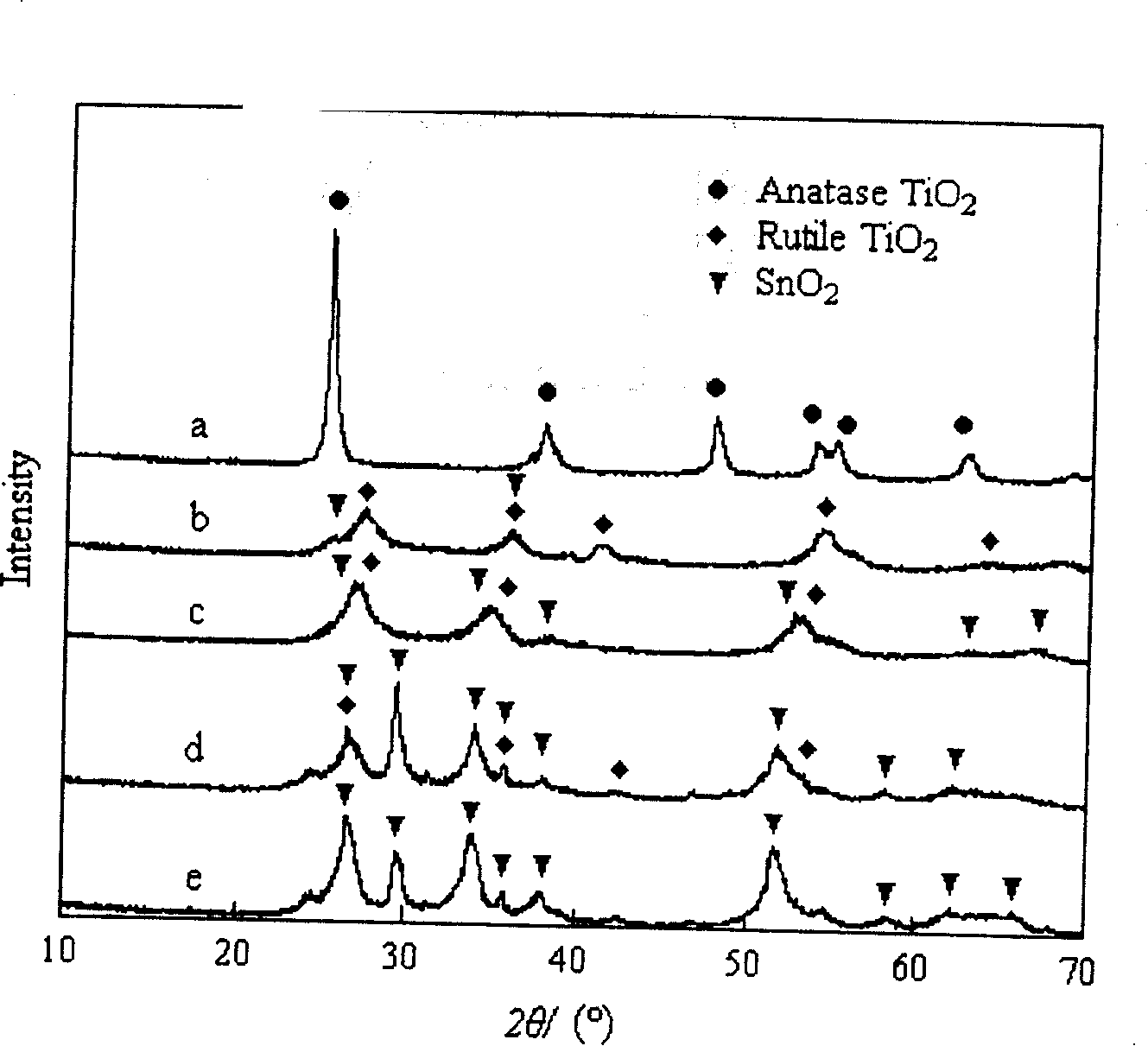

Image

Examples

Embodiment Construction

[0012] 1. The tin salt is tin protochloride (SnCl 2 2H 2 O), get 6.63g, be dissolved in the dehydrated alcohol of 40ml, disperse 30min in the ultrasonic disperser. The titanium salt is butyl orthotitanate (Ti(C 4 h 9 O) 4 ), get 10ml, pour in the 100ml beaker, and slowly pour in the ethanol solution of above-mentioned dispersed stannous chloride, put into magnetic stirrer and stir for 30min. Add 4-5ml deionized water dropwise, measure the pH value every 15 minutes, and control the pH value of the mixture to 9.0 with ammonia water. After the mixture was stirred under a magnetic stirrer for 2 hours, it was left to stand and aged at room temperature for 24 hours. Add 2 to 3 times the volume of distilled water to the aged gel, disperse in an ultrasonic disperser for 30 minutes, then filter and wash twice with a vacuum filter, and wash and filter once with ethanol in the same way. The filtered sample was baked at 100° C. for 12 hours to fully dry it to obtain a composite oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com