An integrated molding method for fabricating three-dimensional rotationally symmetrical microstructures

A technology of three-dimensional rotation and forming method, which is applied in the field of micro-nano optics, can solve the problems of expensive processing equipment, low processing efficiency, complex process flow, etc., and achieve the effect of low processing cost, high processing efficiency and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

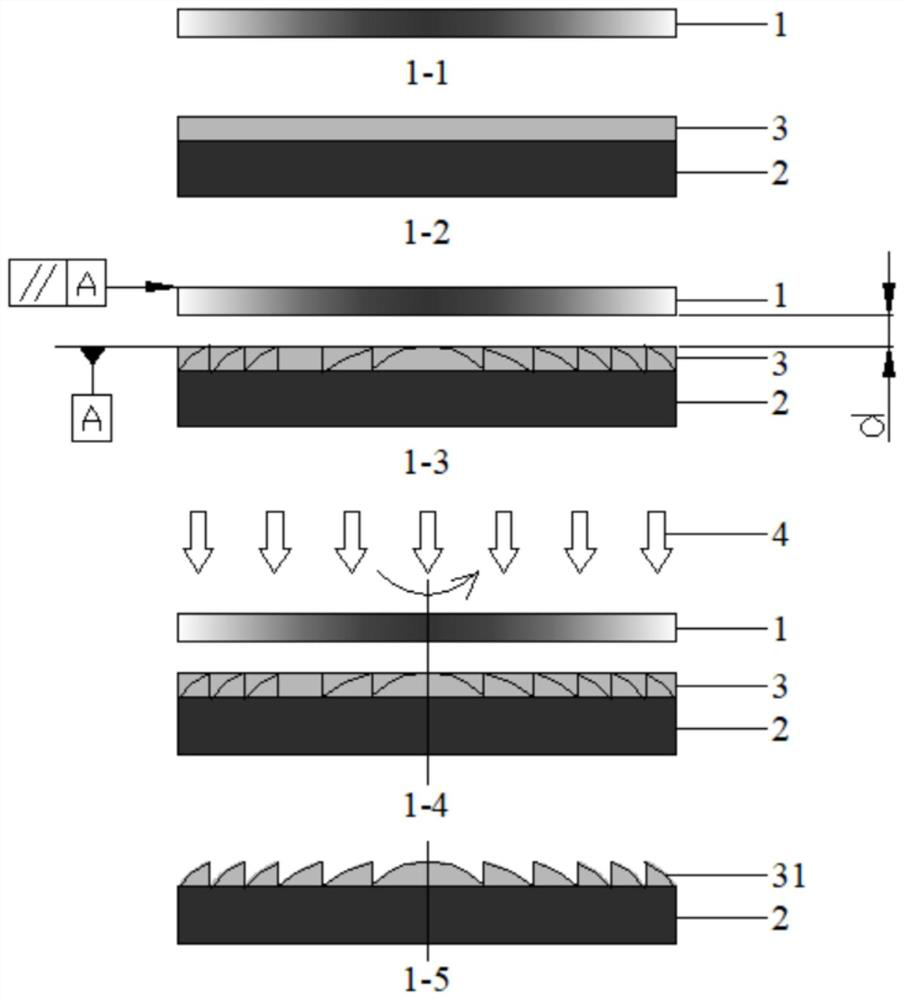

[0025] like figure 1 Shown is a flow chart of an integrated molding method for manufacturing a three-dimensional rotationally symmetric microstructure disclosed in the present invention, which includes the following steps in sequence:

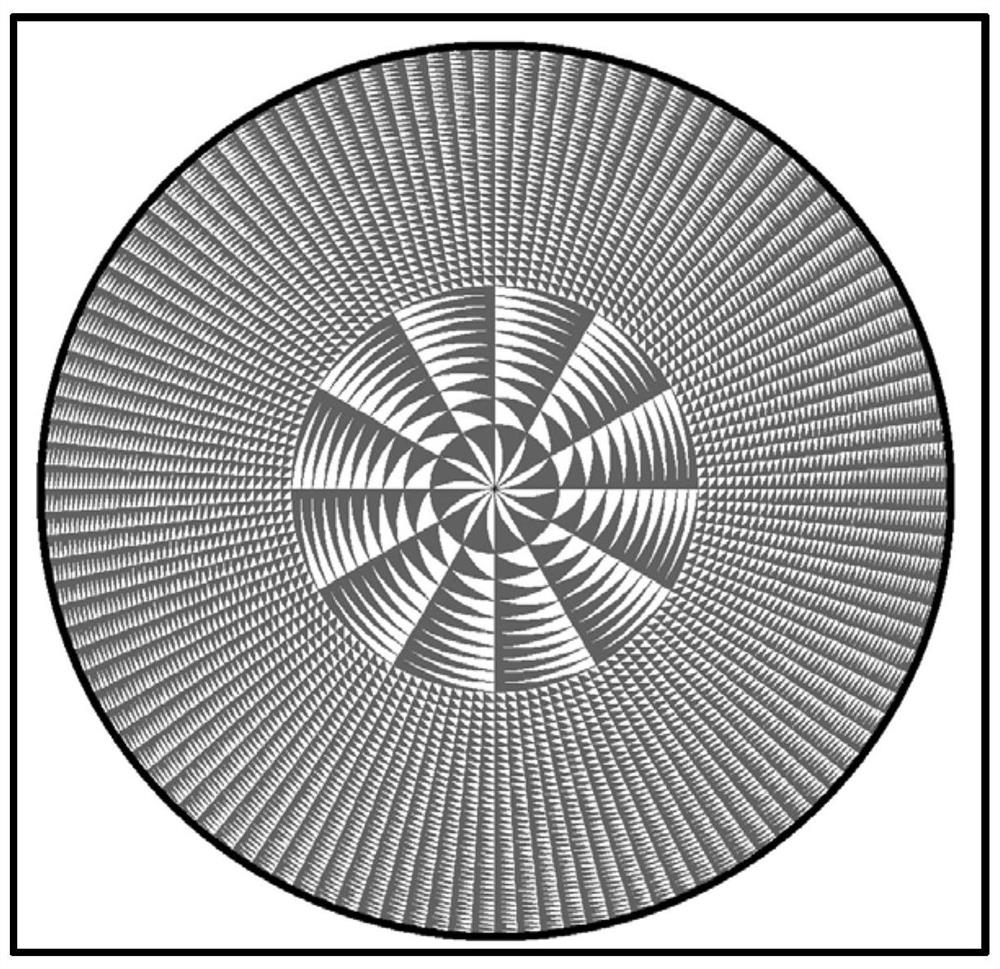

[0026] like figure 1 As shown in middle 1-1, according to the central section shape function of the three-dimensional rotationally symmetrical microstructure 31 of the target, the exposure and development model of the photoresist, and the rotational integral model of the exposure dose, a two-dimensional mask pattern code is designed, such as figure 2 As shown, and use laser direct writing technology to make mask 1;

[0027] like figure 1 As shown in middle 1-2, on the surface of the quartz substrate 2, a layer of AZ 9260 photoresist 3 with a thickness of 7 μm is evenly coated;

[0028] like figure 1 As shown in 1-3, the adjustment mask 1 and the quartz substrate 2 and the photoresist 3 on its surface are kept strictly parallel under the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com