Biotic bone tissue engineering stent and its preparation method

A tissue engineering scaffold and bionic bone technology, which is applied in the field of biomedical materials and tissue engineering, can solve the problems of solid particle sedimentation, uneven particle distribution, and difficult calcium phosphate materials, etc., achieve uniform composition distribution, improve mechanical strength, and improve Effects of Biocompatibility and Osteoconductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

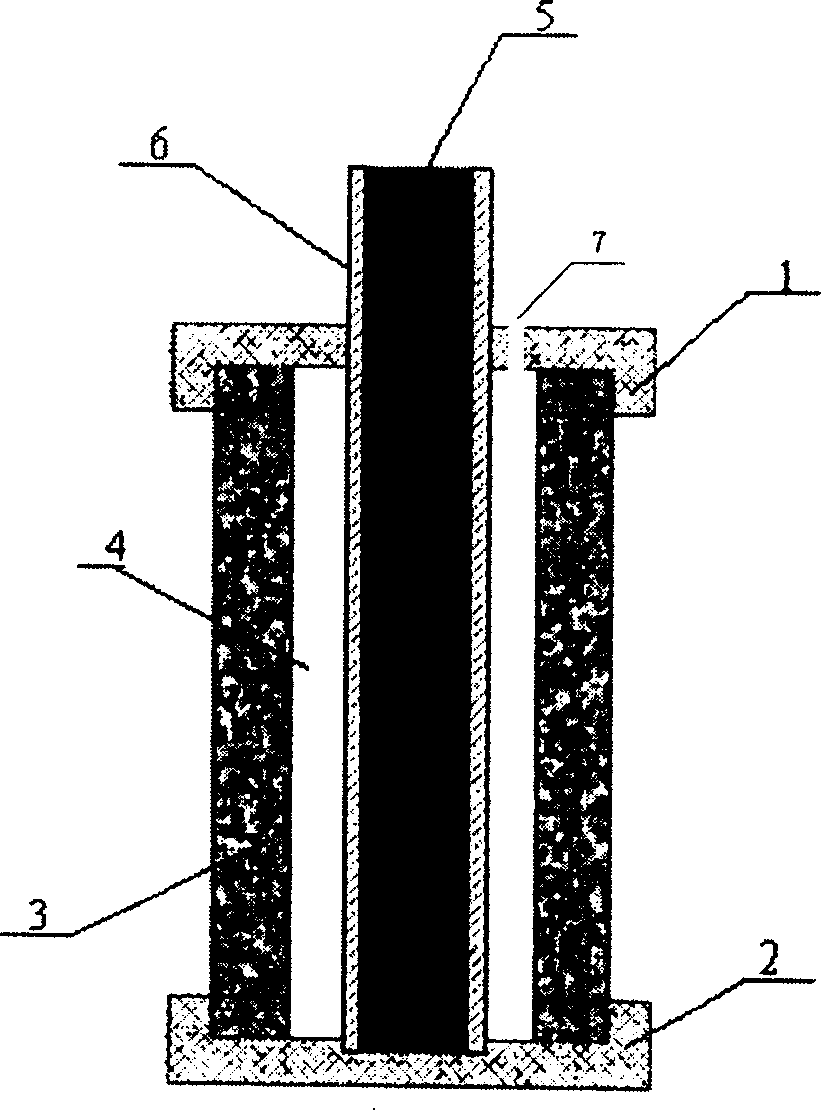

[0029] a) Weigh 2g of chitosan, dissolve it in 50ml of 1.2% acetic acid aqueous solution, and stir until completely dissolved. Take 12ml of 0.1mol / l Ca(NO 3 ) 2 solution and 12ml of 0.06mol / l (NH 4 ) 2 HPO 4 The solution, under strong stirring, is added drop by drop to the chitosan solution in order to ensure that it can be uniformly dispersed as soon as possible after adding a small amount of solution each time, and to avoid the precipitation of chitosan caused by the increase of pH value caused by the local concentration being too high . Stir well to make a completely homogeneous solution. Stand overnight at 4°C or degas with a vacuum pump.

[0030] b) Add the solution in step a) into the cavity 4 of the mold with a syringe, and add slowly to avoid air bubbles. Cover the mold cover 1, put it vertically and slowly into liquid nitrogen, take it out after freezing for 12 hours, remove the top cover 1, bottom cover 2 and stainless steel outer tube 3 after thawing slightly...

Embodiment 2

[0039] a) Weigh 1g of chitosan and 1g of collagen, dissolve them in 50ml of 1.2% acetic acid aqueous solution, and stir until completely dissolved. Take 12ml of 0.1mol / l Ca(NO 3 ) 2 solution and 12ml of 0.1mol / l (NH 4 ) 2 HPO 4 The solution, under strong stirring, is added drop by drop to the chitosan collagen mixed solution in order to ensure that it can be uniformly dispersed as soon as possible after adding a small amount of solution each time, and to avoid the chitosan caused by the increase of the pH value caused by the local concentration being too high. precipitation. Stir well to make a completely homogeneous solution. Stand overnight at 4°C or degas with a vacuum pump.

[0040] b) Add the solution obtained in a) into the cavity 4 of the mold with a syringe, and add slowly to avoid air bubbles. Cover the mold cover 1, place it vertically at -20°C, take it out after freezing for 24 hours, remove the top cover 1, bottom cover 2 and stainless steel outer tube 3 aft...

Embodiment 3

[0048] a) Weigh 1 g of chitosan, dissolve it in 50 ml of 1.2% acetic acid aqueous solution, and stir until it is completely dissolved. An appropriate amount of 2% gelatin aqueous solution was added in the chitosan solution, stirred for 2 hours at 50°C and mixed evenly, and 12ml of 0.1mol / l Ca(NO 3 ) 2 solution and 12ml of 0.05mol / l (NH 4 ) 2 HPO 4 The solution, under strong stirring, is added drop by drop to the chitosan solution in order to ensure that it can be uniformly dispersed as soon as possible after adding a small amount of solution each time, and to avoid the precipitation of chitosan caused by the increase of pH value caused by the local concentration being too high . Stir well to make a completely homogeneous solution. Stand overnight at 4°C or degas with a vacuum pump.

[0049] b) Add the solution obtained in a) into the cavity 4 of the mold with a syringe, and add slowly to avoid air bubbles. Cover the mold cover 1, put it vertically and slowly into liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com