X-ray excited rare-earth ion blended tungstate flash luminous material and its preparing method

A technology of rare earth ions and scintillation, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems that fast imaging can only be used for static imaging, the cost of raw materials is high, and the wide application is limited, so as to facilitate mass production , low cost and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

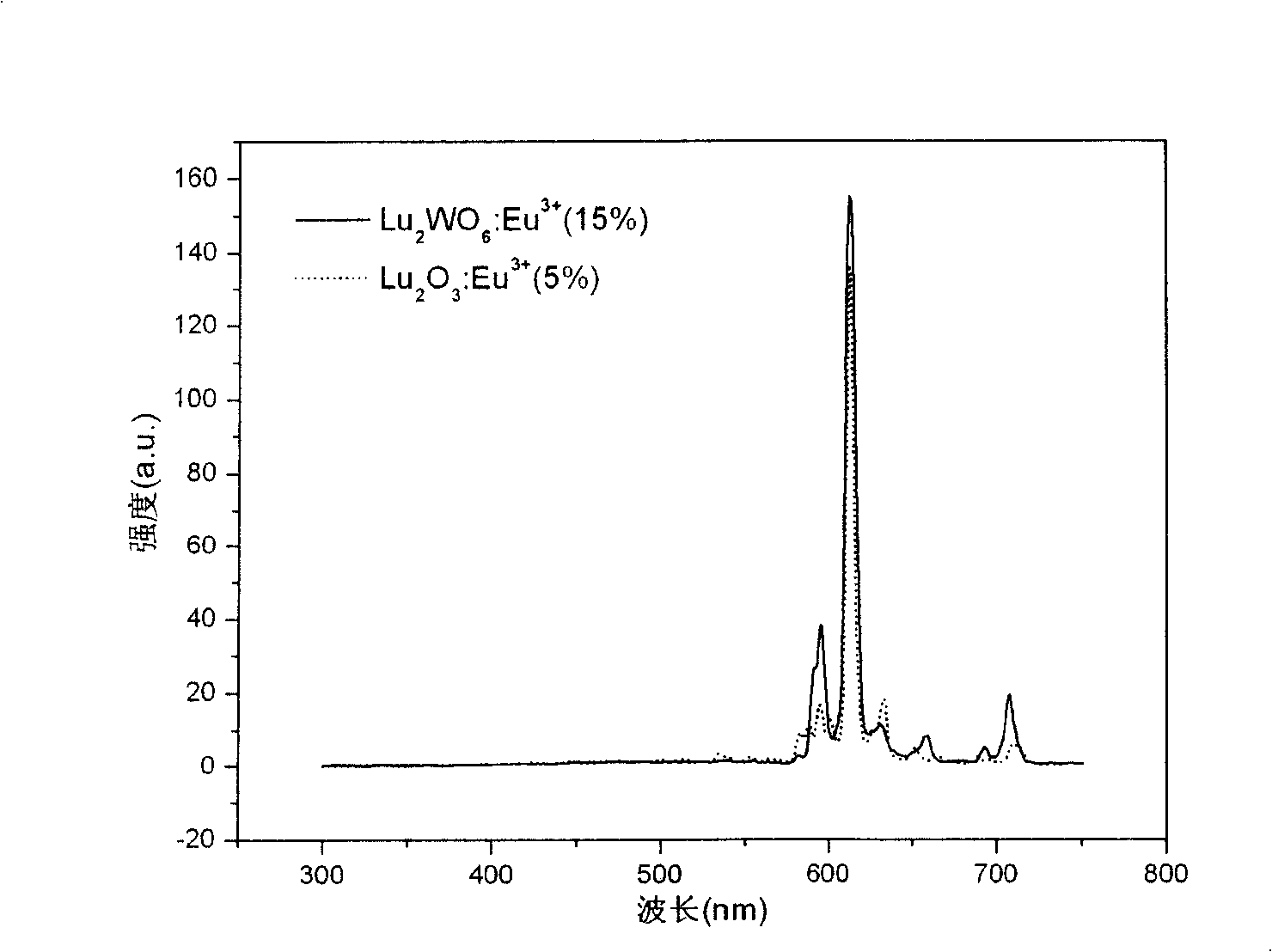

Embodiment 1

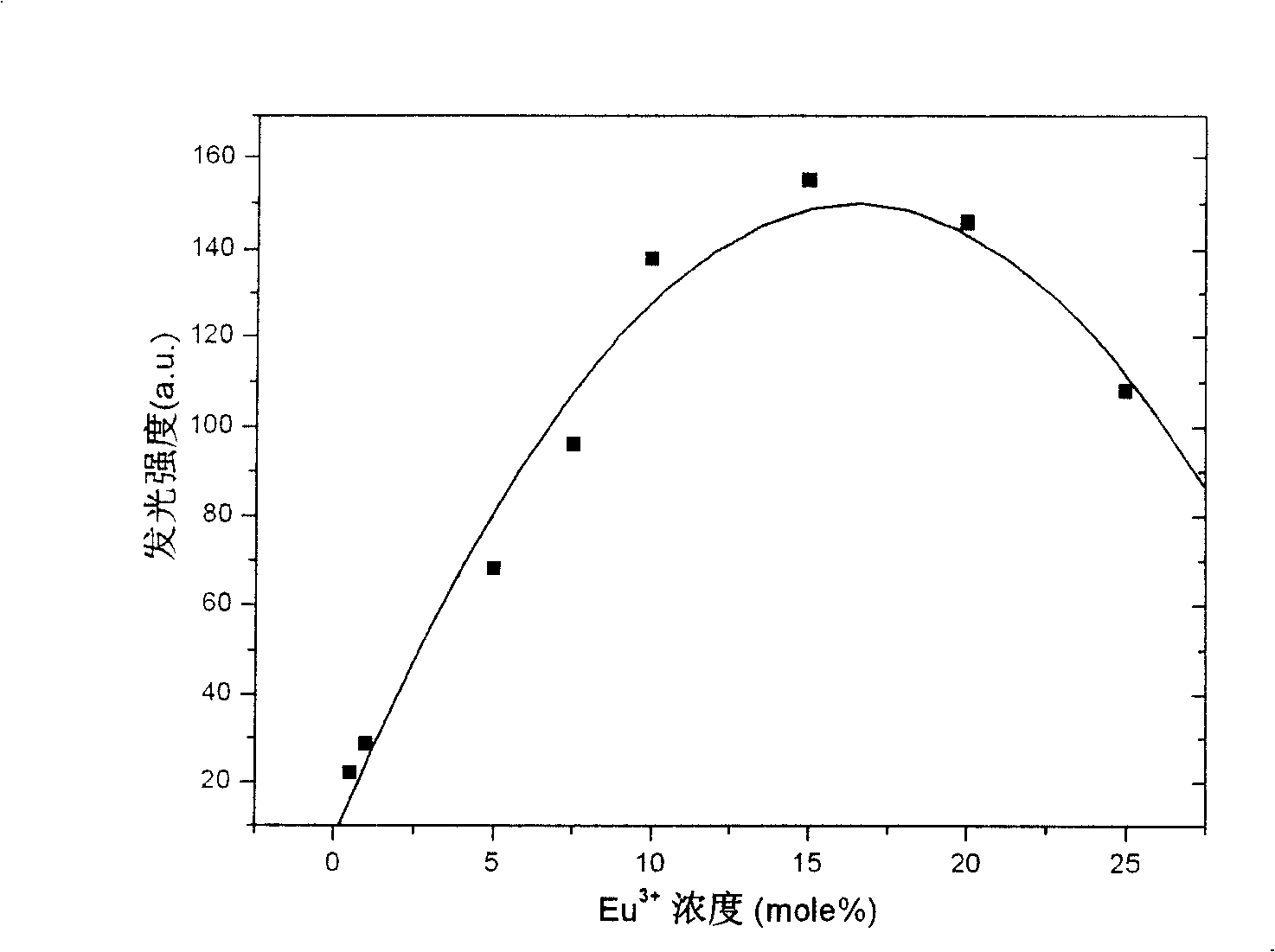

[0017] Weigh Lu 2 O 3 (99.99%) 0.716 g, WO 3 (Analytical grade) 0.464 g, Eu 2 O 3 (99.99%) 0.070g, add absolute ethanol (analytical purity) as a medium, grind and mix thoroughly in an agate mortar, put the obtained mixture into an alumina crucible with a size of 30mm×Φ30mm, and cover the crucible lid. Put it into the Fe-Cr-Al wire heating muffle furnace, heat up from room temperature to 1100°C at a heating rate of 5°C per minute, keep it for 24 hours, and take it out after natural cooling. After grinding, the white product is Lu 1.80 Eu 0.20 WO 6 Red luminous scintillating material.

Embodiment 2

[0019] Weigh Lu 2 O 3 (99.99%) 0.637 g, WO 3 (Analytical grade) 0.464 g, Eu 2 O 3 (99.99%) 0.141 g, using ethanol as the medium, the Al 2 O 3 Grind it in a mortar to make it evenly mixed, then place it in Al 2 O 3 In the crucible, add a lid, put it into a silicon carbide rod furnace at a heating rate of 8°C / min to 1100°C for synthesis. The white product is Lu 1.60 Eu 0.40 WO 6 Red luminous scintillating material.

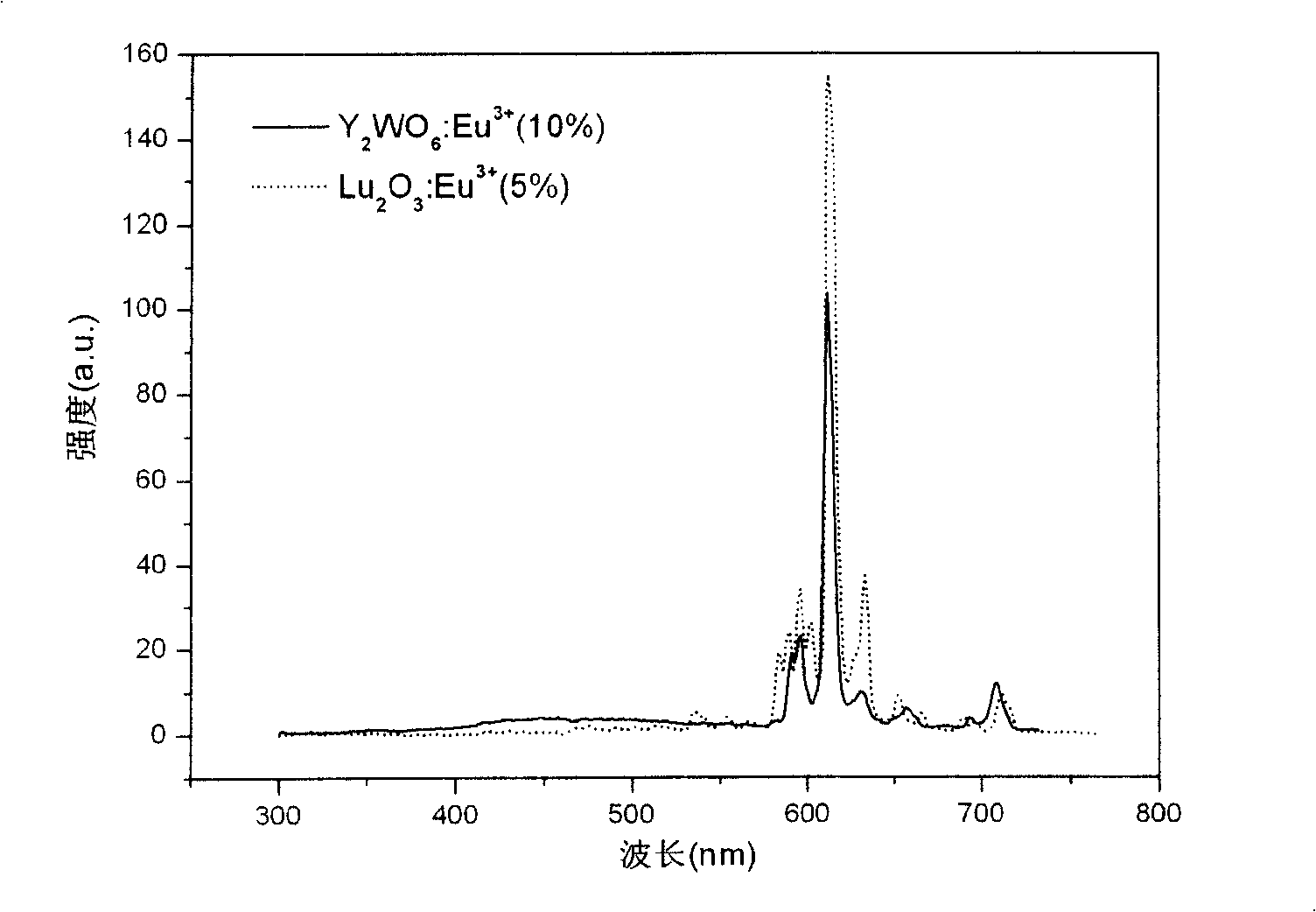

Embodiment 3

[0021] Weigh Y 2 O 3 (99.99%) 0.644 g, WO 3 (Analytical grade) 0.696 g, Eu 2 O 3 (99.99%) 0.053 grams, the rest is the same as in Example 1. The white product is Y 1.90 Eu 0.10 WO 6 Red luminous scintillating material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com