Method of eliminating passivation film for chalcopyrite at lixiviating course by sulfur oxidizing bacteria

A technology for sulfur-oxidizing bacteria and chalcopyrite, which is applied in the direction of improving process efficiency, can solve the problems of low reaction rate, low leaching rate, and limited industrialization and wide application of bioleaching chalcopyrite, and achieves easy colonization and leaching rate. High, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

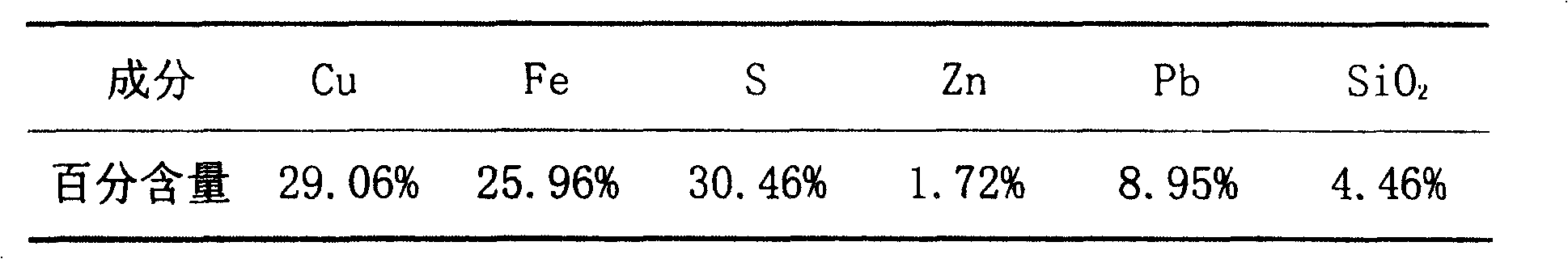

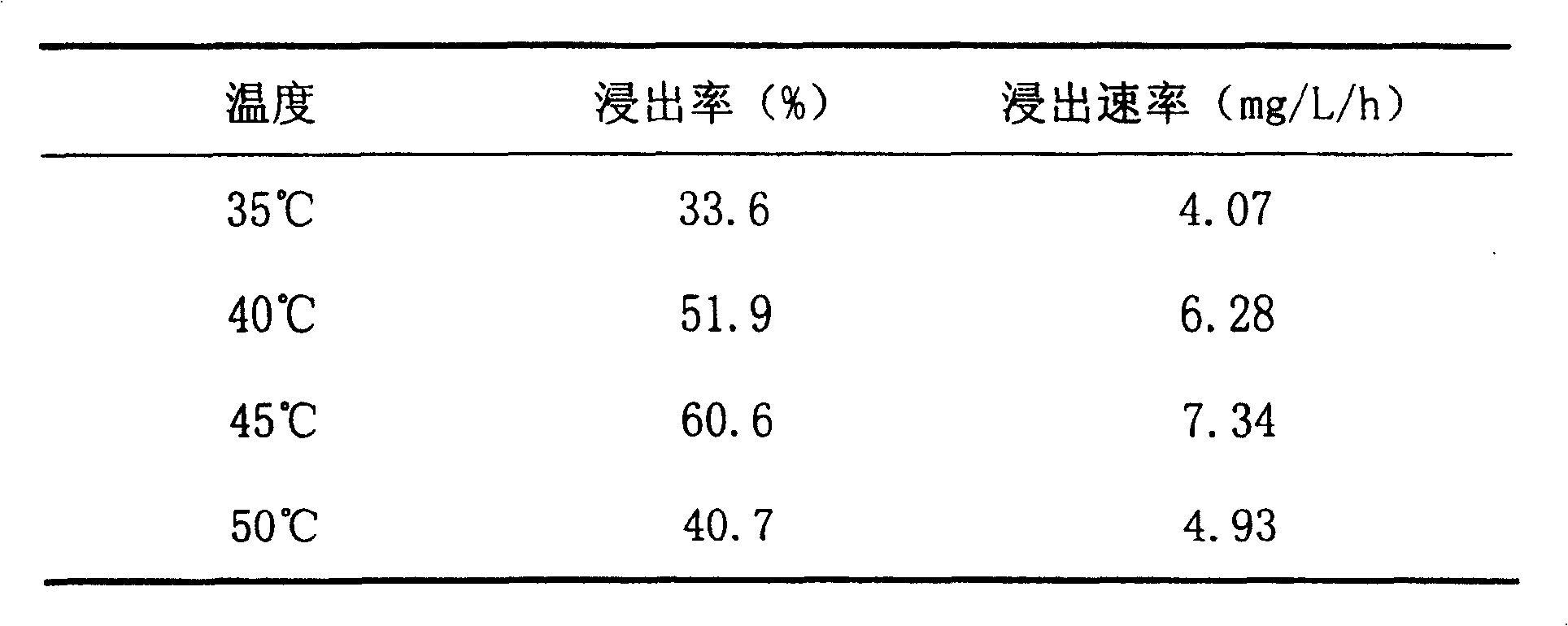

[0015] Embodiment 1. adopts the compound strain that thermophilic Thiobacillus bacterium and Leptospira ferrophilic bacteria concentration ratio is 1: 1 under the condition of 35 ℃, 40 ℃, 45 ℃ and 50 ℃ to chalcopyrite concentrate (composition Analysis see table 1) Carry out 10L stirred tank leaching experiment. The copper content of the ore sample is 29.06%, the iron content is 25.96%, and the sulfur content is 30.46%, mainly primary chalcopyrite. The slurry concentration is 2%, and the bacterial concentration after inoculation is 1×10 7 cells / mL, the initial pH value is 1.6, and the rotation speed is 500rpm. Determination of Cu in Chalcopyrite Leaching Solution by Atomic Absorption Spectrometry 2+ content, and replenish the evaporated water with distilled water at regular intervals. Two groups of parallel experiments. The leaching results after 20 days are shown in Table 2.

[0016] The mass percentage content of the main component of chalcopyrite used in table 1

[001...

Embodiment 2

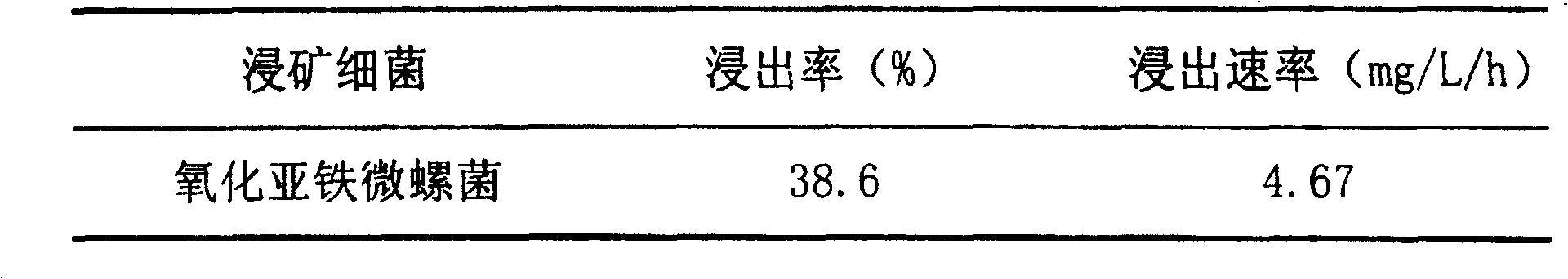

[0021] Embodiment 2. adopting thermophilic Thiobacillus bacterium and the concentration ratio of Leptospira ferrophilic bacteria are respectively 1: 1 / 2, 1: 1 and 1: 2 middle and high temperature compound strains to carry out 10L stirring to chalcopyrite concentrate Tank leaching experiments. The composition of the ore sample is as above. The pulp concentration is 2%, and the bacterial concentration after inoculation is 1~2×10 7 pieces / mL, the leaching temperature is 45°C, the initial pH value is 1.6, and the rotation speed is 500-600rpm. Determination of Cu in Chalcopyrite Leaching Solution by Atomic Absorption Spectrometry 2+ content, and replenish the evaporated water with distilled water at regular intervals. At the same time, chalcopyrite was leached by pure bacteria of Leptospira ferrophilum as a control. The leaching results after 20 days are shown in Table 3.

[0022] Table 3 Comparison of leaching rate and leaching rate of chalcopyrite leached by composite bacter...

Embodiment 3

[0026] Embodiment 3. Adopting the middle and high temperature composite bacterial species that the concentration ratio of thermophilic Thiobacillus bacteria and Leptospira ferrobacterium bacteria is 1:2 carries out 10L of chalcopyrite concentrate that the pulp concentration is 1%, 3% and 5%. Stirred tank leaching experiments. The composition of the ore sample is as above. The bacterial concentration after inoculation was 1~2×10 7 pieces / mL, the leaching temperature is 45°C, the initial pH value is 1.6, and the rotation speed is 500-600rpm. Determination of Cu in Chalcopyrite Leaching Solution by Atomic Absorption Spectrometry 2+ content, and replenish the evaporated water with distilled water at regular intervals. The leaching results after 20 days are shown in Table 4.

[0027] Table 4 Comparison of chalcopyrite leaching rate and leaching rate under different pulp concentrations

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com