Atmospheric synthetic method for high purity titamum aluminum carbide ceramic powder

A technology of aluminum-titanium carbide and ceramic powders is applied in the field of atmospheric synthesis of high-purity aluminum-titanium carbide Ti3AlC2 ceramic powders, which can solve the problems of severe temperature fluctuations in the furnace, unstable process parameters, and influence on the purity of the composites. The effect of reducing high temperature loss, easy stabilization of sintering process parameters, and short synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0026] 1) According to the molar ratio of Ti:Al:TiC:Sn=1:1:1:0.1, weigh 24.6 grams of Ti powder, 13.9 grams of Al powder, 30.8 grams of TiC powder, and 6.1 grams of Sn powder.

[0027] 2) Put the above ingredients into a ball mill tank and mix for 5 hours.

[0028] 3) Press the homogeneously mixed ingredients into a block under a pressure of 10 MPa.

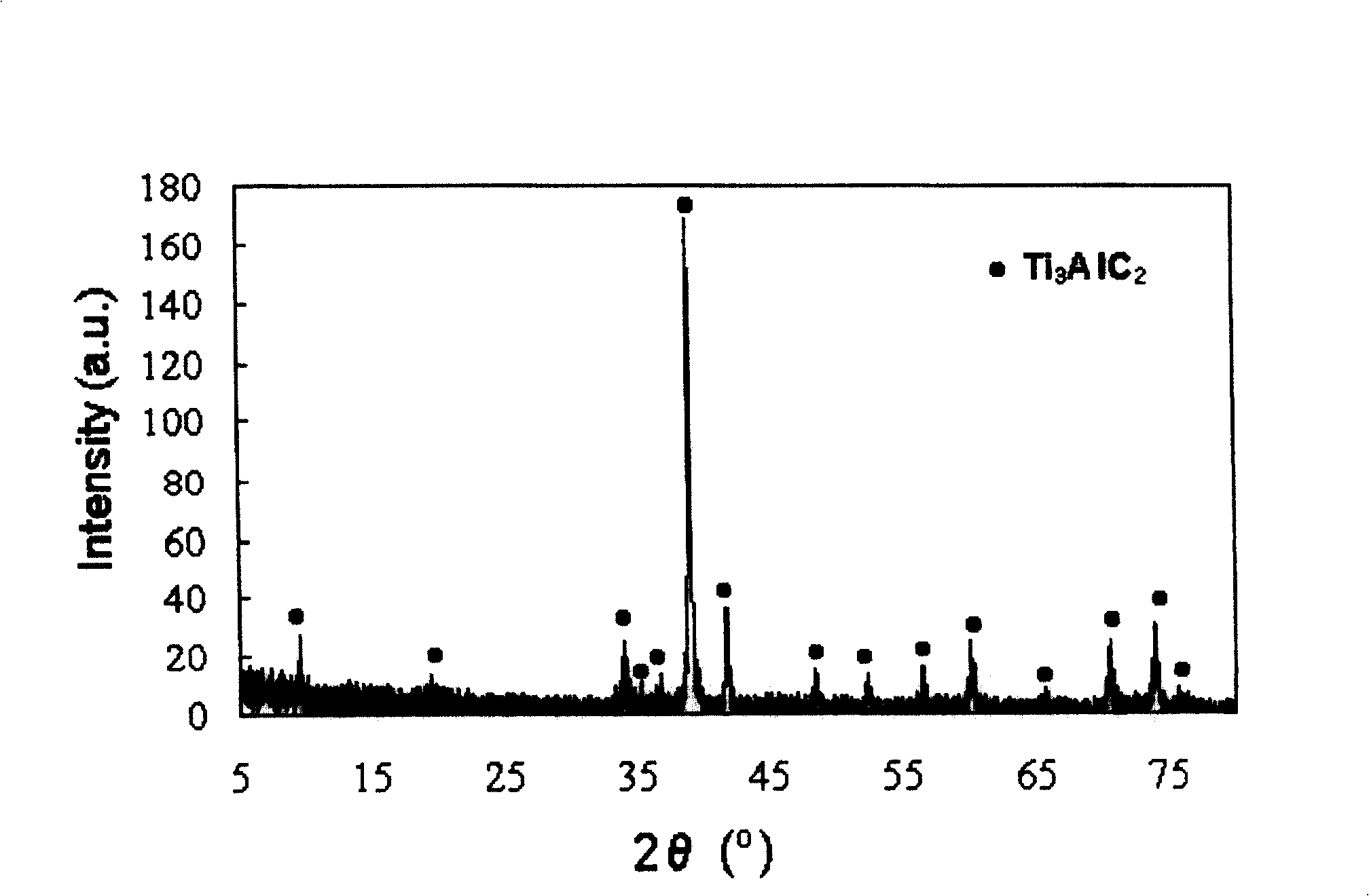

[0029] 4) Put the above briquette into a high-temperature furnace, protect the atmosphere with argon gas, raise the temperature of the furnace to 1350°C at a heating rate of 30°C / min, and keep the holding time for 15min to obtain high-purity Ti 3 AlC 2 powder, the X-ray diffraction (XRD) pattern of powder sees attached figure 1 . It can be seen from the figure that the product has high purity, and there is no impurity phase such as TiC in the XRD spectrum.

Embodiment approach 2

[0031] 1) According to the molar ratio of Ti:Al:TiC:Sn=1:1:1:0.1, weigh 24.6 grams of Ti powder, 13.9 grams of Al powder, 30.8 grams of TiC powder, and 6.1 grams of Sn powder.

[0032] 2) Put the above ingredients into a ball mill tank and mix for 5 hours.

[0033] 3) Press the homogeneously mixed ingredients into a block under a pressure of 10 MPa.

[0034]4) Put the above briquette into a high-temperature furnace, protect the atmosphere with argon gas, raise the temperature of the furnace to 1400°C at a heating rate of 40°C / min, and hold the temperature for 10 minutes to obtain high-purity Ti 3 AlC 2 Powder, its XRD result is identical with embodiment one.

Embodiment approach 3

[0036] 1) According to the molar ratio of Ti:Al:TiC:Sn=1:1:1:0.15, weigh 28.7 grams of Ti powder, 16.2 grams of Al powder, 35.9 grams of TiC powder, and 10.7 grams of Sn powder.

[0037] 2) Put the above ingredients into a ball mill tank and mix for 6 hours.

[0038] 3) Press the homogeneously mixed ingredients into a block under a pressure of 30 MPa.

[0039] 4) Put the above briquette into a high-temperature furnace, protect the atmosphere with argon gas, raise the temperature of the furnace to 1450°C at a heating rate of 40°C / min, and hold the temperature for 15 minutes to obtain high-purity Ti 3 AlC 2 Powder, its XRD result is identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com