Etching method and composition for forming etching protective layer

An etching protection and composition technology, which is applied to photosensitive materials for opto-mechanical equipment, photo-engraving processes for patterned surfaces, instruments, etc. Problems such as pattern-transferring shape deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0030] (Formation of resist pattern)

[0031] Positive photoresist AZ 7900 (i-line resist) ("AZ" is a registered trademark) produced by Clariant Japan K.K. was coated using a spin coater produced by Lithotech Japan Co., LARCULTIMA-1000 onto a 6-inch silicon wafer with a 1 μm oxide film and treated with HMDS. The coated silicon wafer was preheated on a heating plate at 100° C. for 60 seconds, and a resist film with a thickness of 1 μm was formed. The film thickness was measured by a film thickness measuring device produced by Dai-Nippon Screen Co. (Lambda Ace). Then, the silicon wafer is exposed, using a stepper (produced by Nikon Co., NSR 1755iB, NA=0.54) of i-line (365nm) exposure wavelength, through a reticle of a line and space pattern with a width of 0.3 μm. Change exposure in steps. The exposed silicon wafer was heated on a hot plate at 100° C. for 90 seconds. At 23°C, the silicon wafer was developed by paddle development for 1 minute, and AZ 300MIF Developer produced...

reference example 2

[0050] Using a spin coater (Mark 8) produced by Tokyo Electron Co., a positive-type photoresist (KrF resist) consisting of the composition described below was applied onto a 6-inch silicon wafer, which There is a 1μm oxide film and treated with HMDS. The coated silicon wafer was preheated on a heating plate at 90° C. for 60 seconds, and prepared to form a resist film with a thickness of 0.7 μm. The film thickness was measured by a film thickness measuring device produced by Dai-Nippon Screen Co. (Lambda Ace). Then, the silicon wafer was exposed, using a stepper with 248nm exposure wavelength (produced by Canon Co., FPA3000EX5, NA=0.63), and the exposure amount was changed step by step through a reticle with a line and space pattern of 0.3 μm width. The exposed silicon wafer was heated on a hot plate at 110° C. for 90 seconds. At 23°C, the silicon wafer was developed by paddle development for 1 minute, and AZ 300MIF Developer produced by Clariant Japan K.K. was used as an alk...

Embodiment 1

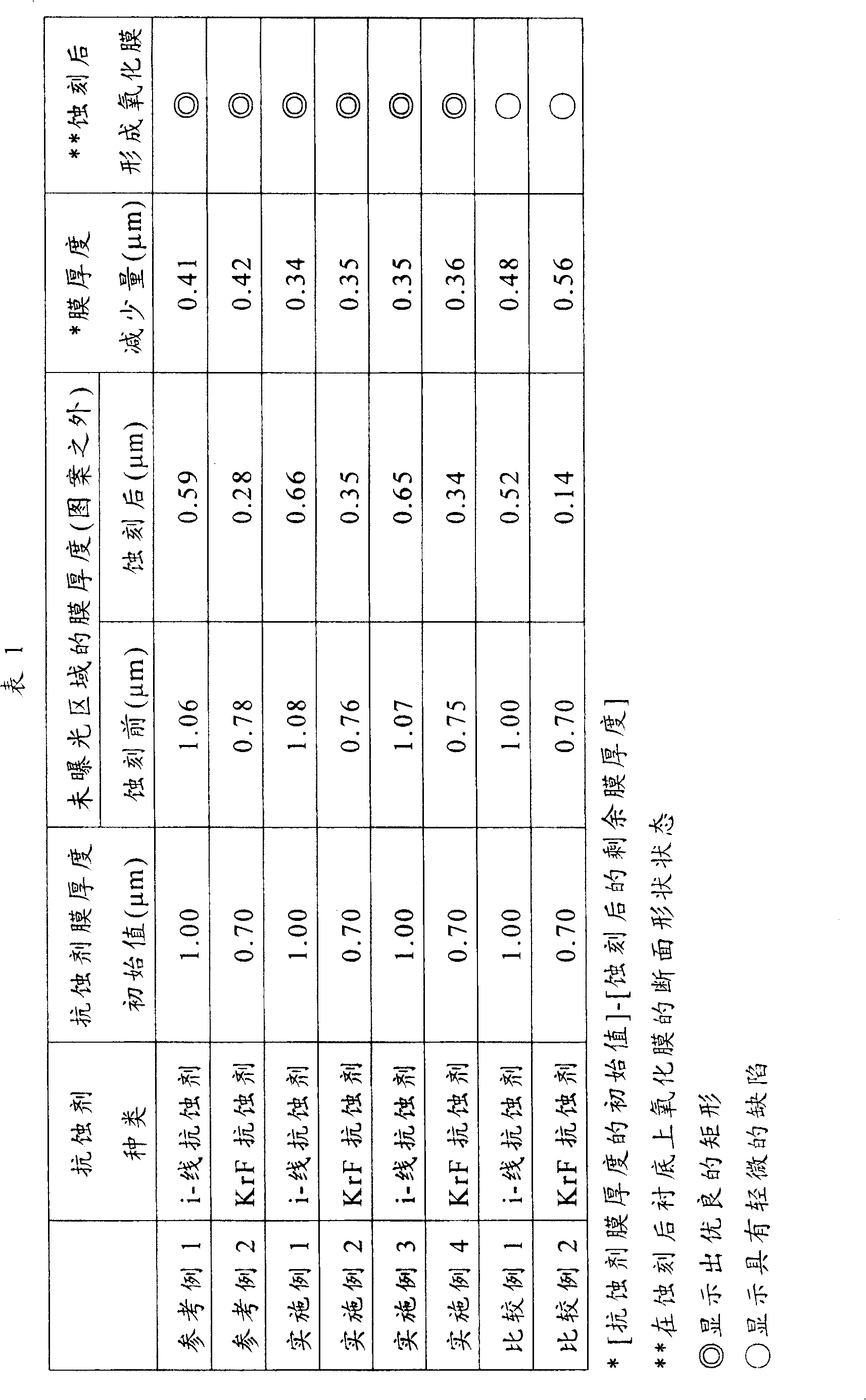

[0058] An etching mask having an etching protective layer was formed in the same manner as in Reference Example 1 except that Composition B for forming an etching protective layer prepared as described below was used instead of Composition A for forming an etching protective layer. Etching was performed on a substrate having an etching mask in the same manner as in Reference Example 1, and the etching resistance of the resist mask was evaluated. The results are shown in Table 1.

[0059] (Preparation of composition B for forming an etch protection layer)

[0060] Mix each of the components described below in the proportions described below, stir well and dissolve. Composition B for forming an etching protective layer was prepared after filtering the composition through a 0.2 μm filter.

[0061] Component Parts by weight

[0062] Copolymer of acrylic acid and p-hydroxystyrene (85 / 15 molar ratio) 2.0

[0063] Methoxymethylated melamine 0.5

[0064] 2-propanol 2.5

[0065] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com