Technique and equipment for treating electroplating sludge

A technology for electroplating sludge and treatment process, which is applied to the improvement of process efficiency, electrolysis process, electrolysis components, etc., can solve the problems of excessive dust, large coke consumption, low recovery rate, etc., achieve large processing capacity, improve sintering efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

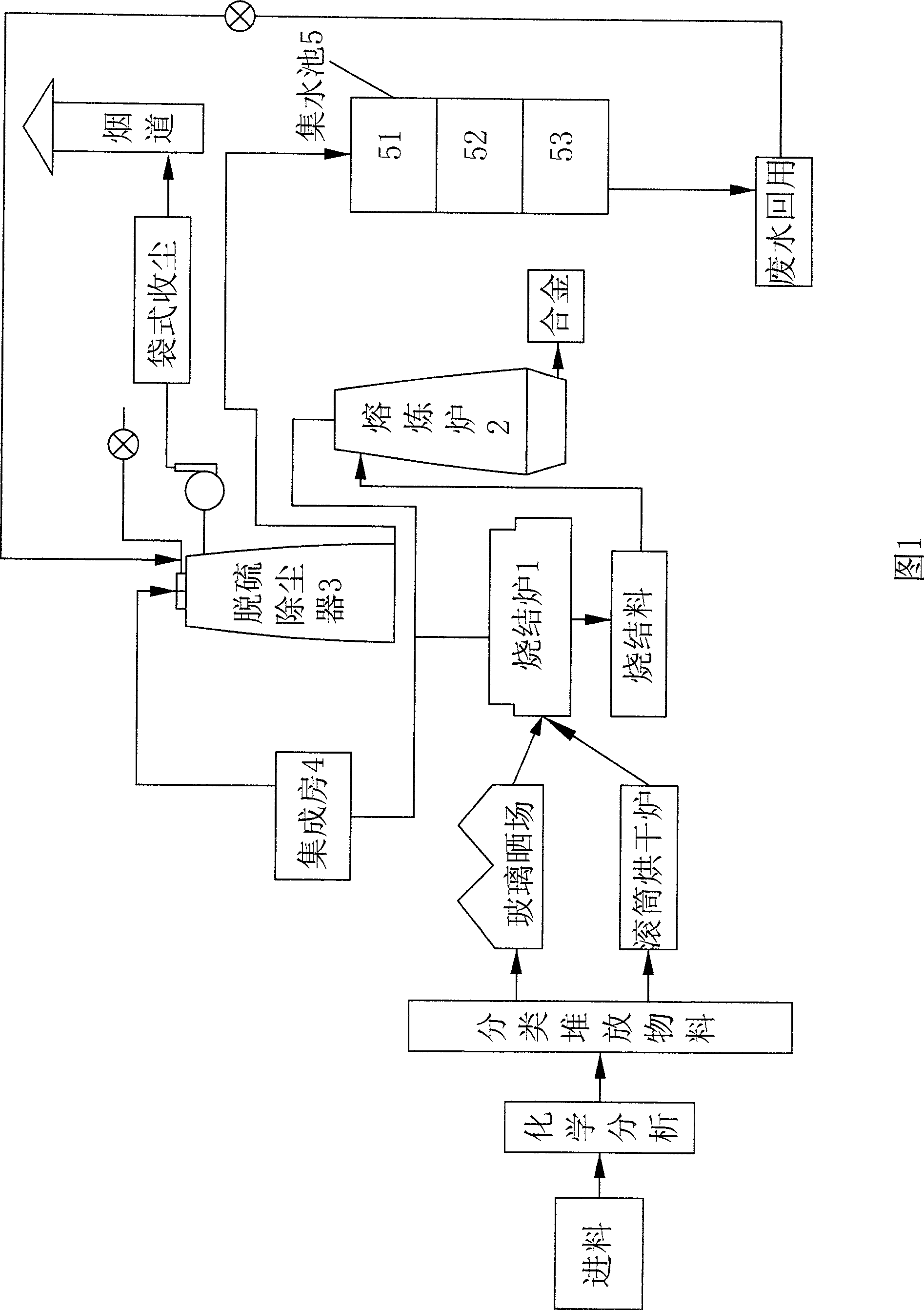

[0031] See Figure 1 to Figure 13 , The electroplating sludge treatment device of the present invention includes a sintering furnace 1, a smelting furnace 2, a desulfurization and dust removal device 3, a dust collection room 4 and a sump 5.

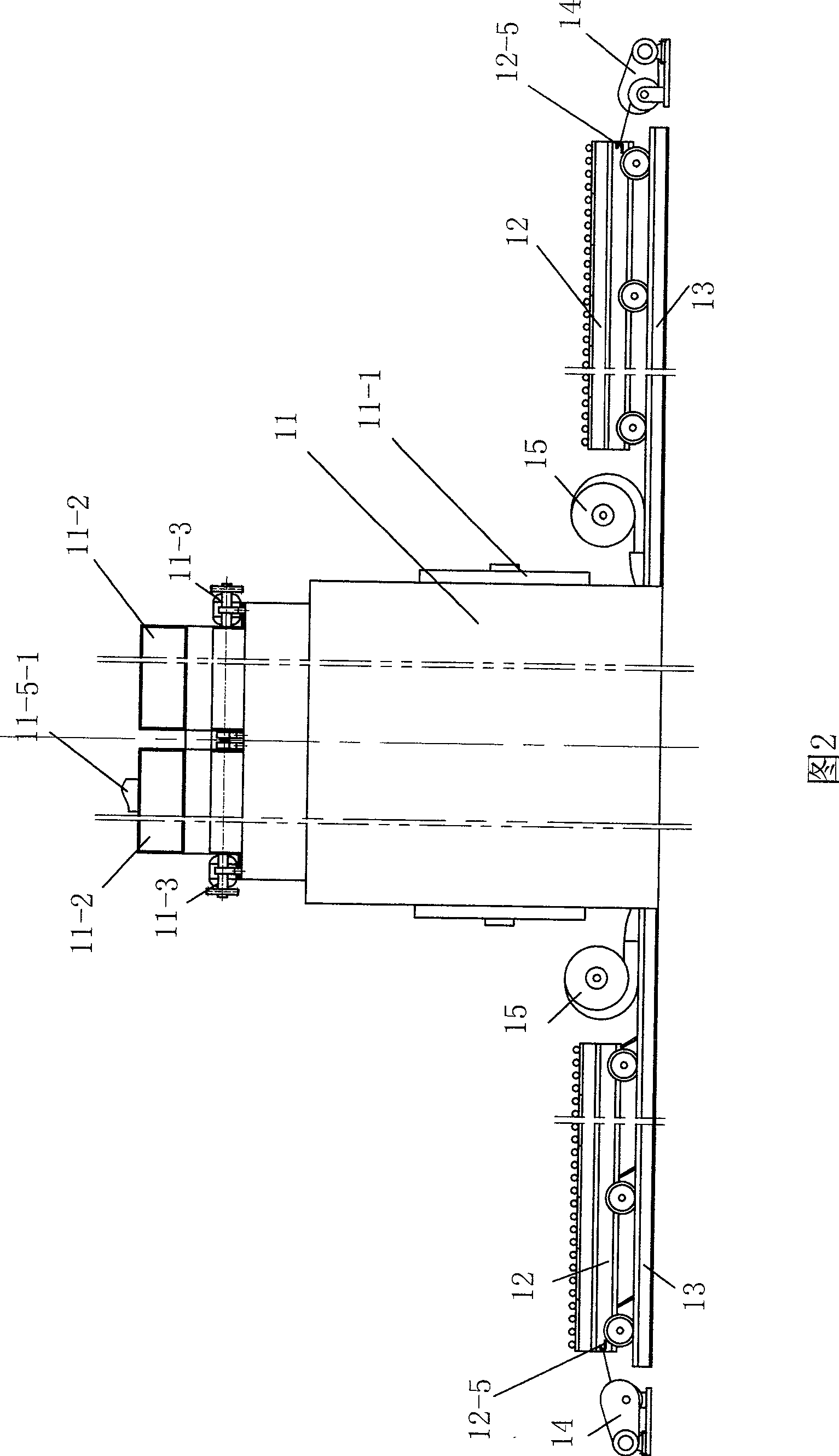

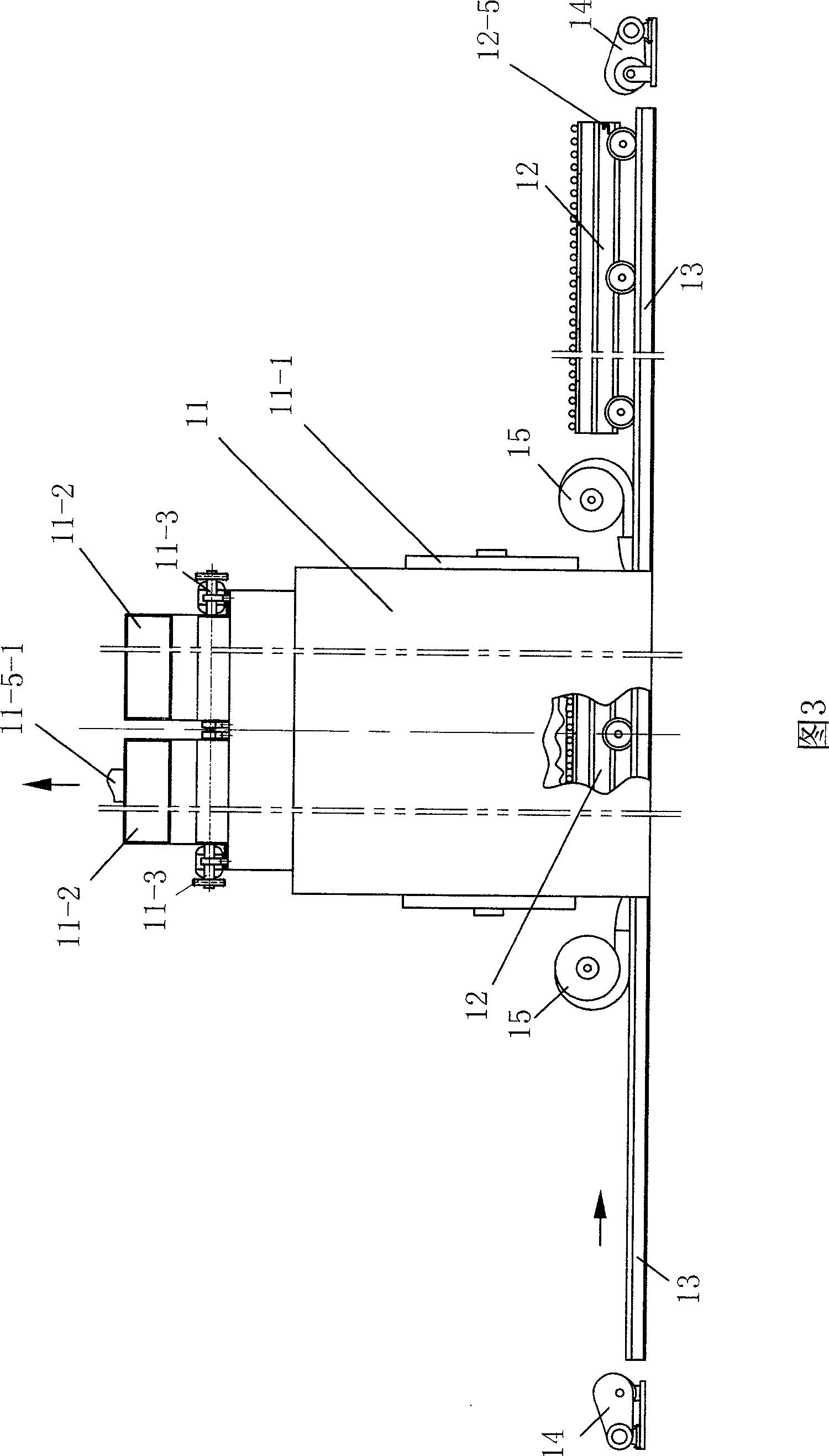

[0032] The sintering furnace 1 includes a furnace body 11 and a furnace car 12, and a light rail 13 cooperating with the furnace car 12 to roll. In order to facilitate continuous production and improve the throughput, two sets of the furnace car 12 and the light rail 13 of the present invention are arranged, respectively located on two sides of the furnace body 11. side. The inboard of body of furnace 11 adopts refractory material to build by laying bricks or stones, and lower half both sides are respectively provided with a cast iron plate 11-10, and this cast iron plate 11-10 is about 1 meter high, wide about 0.2cm, because temperature in body of furnace 11 is very high, Especially in the area with material 1 meter below, the cast iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com