Method for reducing Fe(III)EDTA in solution and uses thereof

A solution and mixed solution technology, applied in the field of environmental pollution control, can solve the problems of reducing NO absorption rate, low regeneration rate, loss of complexation ability, etc., and achieve the effects of avoiding secondary pollution, increasing reduction rate, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

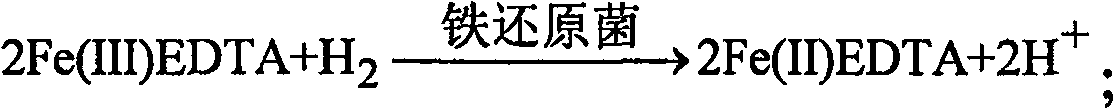

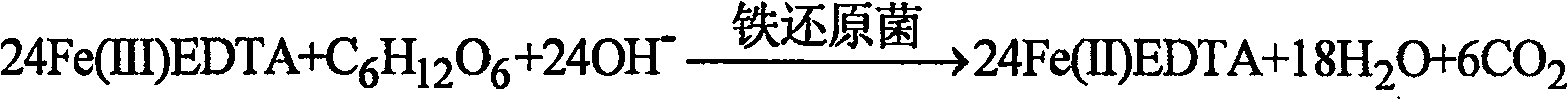

Method used

Image

Examples

Embodiment 1

[0030] 3mmol FeCl 3 4H 2 O, 3mmol Na 2 h 2 EDTA was dissolved in water to make Fe(III)EDTA solution, then 30mmol glucose and basal medium concentrate were dissolved in the above solution to make 1L mixed solution, the pH value of the mixed solution was adjusted to 6.5, and the concentration of Fe(III)EDTA in the solution The concentration of the basal medium is 3mmol / L, the concentration of the basal medium is consistent with the concentration of the basal medium of the enrichment culture, and then the mixed solution is poured into the reactor; at a temperature of 50°C, the physical electrode with the iron-reducing bacteria film Put it into the mixed solution and electrify, where the current density is 0.03mA / cm 2 , after reduction reaction 3 hours, the Fe(III)EDTA in the reactor is 0.2mmol / L.

Embodiment 2

[0032] 5mmol Fe 2 (SO 4 ) 3 , 10mmolNa 2 h 2 EDTA is dissolved in water and makes Fe(III)EDTA solution, then 30mmol ethanol and basal medium concentrate are dissolved in above-mentioned solution to make 1L mixed solution, the pH value of adjusting mixed solution is 5, the Fe(III)EDTA in the solution The concentration of the basal medium is 10mmol / L, the concentration of the basal medium is the same as that of the enriched culture, and then the mixed solution is poured into the reactor; at a temperature of 30°C, the electrode with the iron-reducing bacteria film is placed Into the mixed solution and electrified, where the current density is 0.01mA / cm 2 , after reduction reaction 6 hours, the Fe(III)EDTA in the reactor is 3.4mmol / L.

Embodiment 3

[0034] 10mmol FeCl 3 4H 2 O, 10mmol Na 3 HEDTA is dissolved in water, then 30mmol sodium acetate and basal medium concentrate are dissolved in above-mentioned solution and make 1L mixed solution, the pH value of adjusting mixed solution is 6.5, the Fe(III)EDTA concentration in the solution is 10mmol / L, basic The concentration of the medium is consistent with the concentration of the basal medium for enrichment culture, and then the mixed solution is poured into the reactor; at a reaction temperature of 60°C, the electrode with the iron-reducing bacteria film is placed in the mixed solution and energized , where the current density is 0.59mA / cm 2 , after reducing for 6 hours, the Fe(III)EDTA in the reactor was 2.9mmol / L

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com