Method for preparing high optical electrical conductibility poly-p-vinylbenzene/phthalocyanine composite material

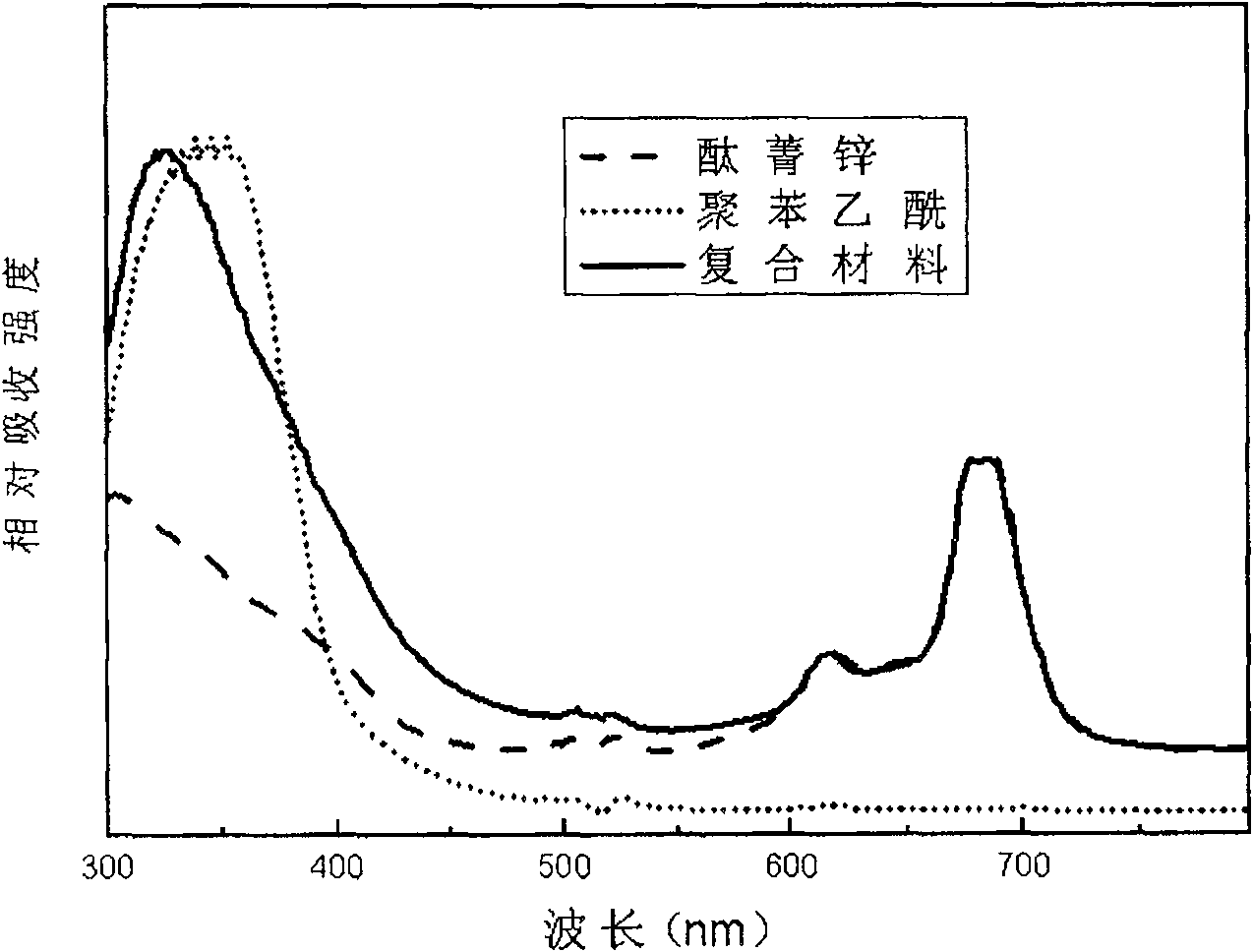

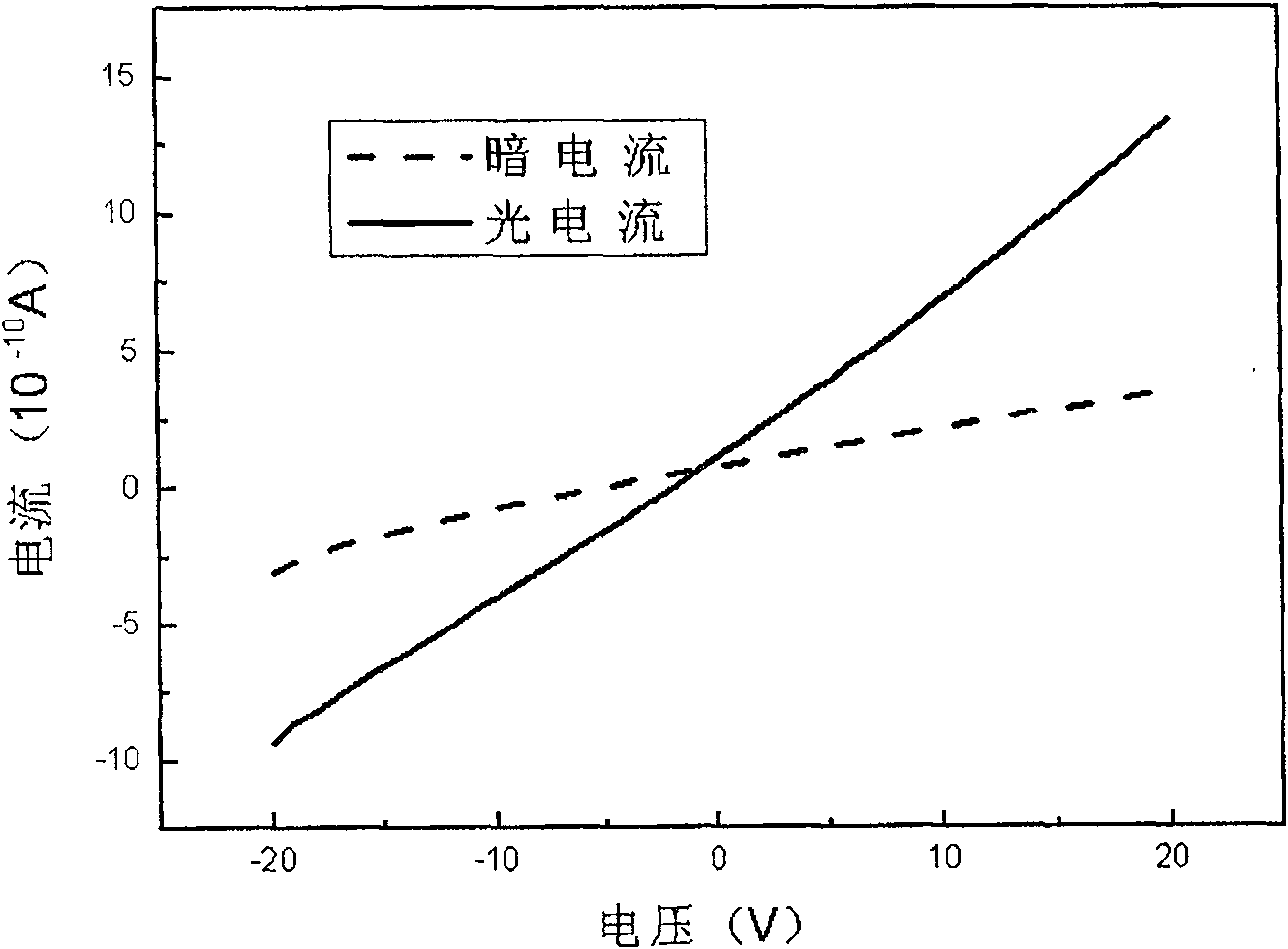

A technology of poly(p-phenylene vinylene) and photoconductivity, which is applied in the field of functional materials, can solve the problems of low photoconductivity and achieve the effects of improving light absorption range, good solubility and film-forming properties, and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The concrete steps of this embodiment are as follows:

[0027] 1. Mix 8.84g of phthalic anhydride, 2.63g of zinc acetate, 55.2g of urea and 0.20g of ammonium molybdate tetrahydrate and grind them evenly with a mortar, then add them to a 500ml three-necked flask, and then add 100ml of nitrobenzene as solvent. Put the three-necked flask into an oil bath and heat it to 190°C while stirring with an electric mixer. After reacting for 5 hours, cool and filter, and wash the filter residue with methanol until there is no nitrobenzene smell. The solid powder obtained by the reaction was boiled with 1mol / L hydrochloric acid solution for 30 minutes, filtered and then boiled with 1mol / L sodium hydroxide solution for 30 minutes, filtered, finally washed with deionized water until neutral, and dried to obtain amide phthalocyanine zinc Add 2.0g zinc amide phthalocyanine and 50ml hydrochloric acid into a 250ml flask, stir at 100°C for 24 hours, filter after cooling, wash the filter re...

Embodiment 2

[0033] This embodiment is basically the same as the above-mentioned embodiment, the difference is:

[0034]1. Mix 17.68g of phthalic anhydride, 5.26g of zinc acetate, 55.20g of urea and 0.30g of ammonium molybdate tetrahydrate and grind them evenly with a mortar, then add them to a 500ml three-necked flask, and then add 200ml of nitrobenzene as solvent for the reaction. The solid powder obtained by the reaction was boiled with 1mol / L hydrochloric acid solution for 30 minutes, filtered and then boiled with 1mol / L sodium hydroxide solution for 30 minutes, filtered, finally washed with deionized water until neutral, and dried to obtain amide phthalocyanine zinc ; Add 2.40g zinc amide phthalocyanine and 60ml hydrochloric acid into a 250ml flask, and stir at 100°C for 24 hours. After cooling, filter, wash the filter residue with deionized water several times, then dissolve the filter residue with 0.50mol / L KOH and filter, titrate the filtrate with 1mol / L hydrochloric acid to a pH ...

Embodiment 3

[0040] This embodiment is basically the same as the above-mentioned embodiment, the difference is:

[0041] 1. Weigh 2.63g of zinc acetate, 8.84g of phthalic anhydride, 55.20g of urea and 0.20g of ammonium molybdate tetrahydrate and mix them evenly, then add them to a 500ml three-necked flask, then add 200ml of nitrobenzene as a solvent to react to obtain Amide phthalocyanine zinc; add 1g amide phthalocyanine zinc and 25ml hydrochloric acid into a 100ml flask, stir at 100°C for 24 hours, filter after cooling, wash the filter residue with deionized water several times and then dry to obtain carboxyl phthalocyanine zinc; 1.2g Zinc carboxyphthalocyanine, 3.6ml of thionyl chloride, and a few drops of pyridine were stirred and reacted in 12ml of benzene for 10 hours, and after the reaction was completed, the acid chloride phthalocyanine zinc was obtained by drying;

[0042] 2. Evaporate the solvent with a mechanical pump and a rotary evaporator;

[0043] 3. Dissolve 0.3g of polyph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com