Method for preparing high water soluble nano carbon tube grafted by super branched polymer

A technology of hyperbranched polymers and carbon nanotubes, applied in the field of nanomaterials, can solve the problems of poor solubility of products, materials that cannot reflect the characteristics of carbon nanotubes, and low content of carbon nanotubes, and achieves water solubility and excellent dispersion. The effect of simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using the multi-walled carbon nanotubes prepared by catalytic pyrolysis as the initial raw material, the carbon nanotubes are purified by strong oxidizing acid to remove impurities in the raw materials, and at the same time, the carbon nanotubes are chopped. Utilizing the action of active groups appearing on the surface of carbon nanotubes after chopping and polyamines, a certain hyperbranching initiating group is modified on the surface of carbon nanotubes. Then react with hyperbranched poly(amide-ester) (the number of hyperbranched polymers is five generations) synthesized by phenyl anhydride (benzene-1,2,4-tricarboxylic acid-1,2 anhydride) and diethanolamine to obtain hyperbranched Poly(amide-ester) grafted carbon nanotubes.

[0024] Step (a): Put 2 g of dry multi-walled carbon nanotubes and 40 mL of 60% concentrated nitric acid into a 100 mL flask equipped with a magnetic stirrer, and reflux for 24 h under magnetic stirring at 80 ° C; discard the upper layer liquid ...

Embodiment 2

[0029] On the basis of Example 1, step (a) is the same as Example 1, and the input amount of diethanolamine is changed to 1.4g in step (b), and 10% metaphthalic anhydride (benzene-1,2,4- Tricarboxylic acid-1,2 anhydride) and diethanolamine synthesized hyperbranched poly(amide-ester) (hyperbranched polymer generation number is five generations) DMF solution input amount is changed into 40mL, other conditions are constant, obtained black powder The graft modification of hyperbranched poly(amide-ester) carbon nanotubes.

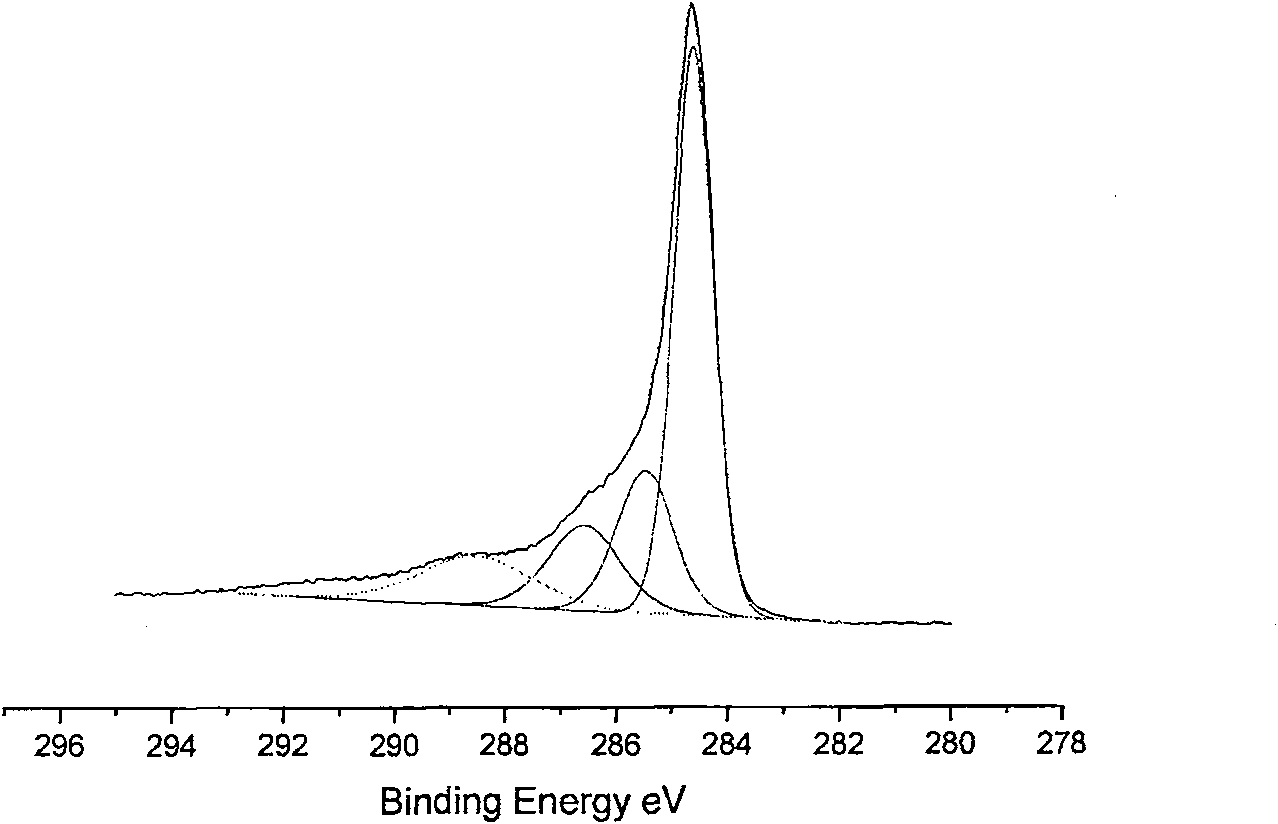

[0030] Compared with the product obtained in the examples, the content of N elements (8.1%) and O elements (0.62% becomes 14%) changes more obviously in the elemental analysis, and the peak values of amido and carboxyl groups in the XPS analysis results are higher than those in Example 1. The map is larger, the result is clearer and more obvious, and the dispersion performance of the modified product in water is improved to a certain extent (20mg / mL)

Embodiment 3

[0032] On the basis of Example 1, step (a) is the same as Example 1, and the input amount of diethanolamine is changed to 2.1g in step (b), and 10% metaphthalic anhydride (benzene-1,2,4- Tricarboxylic acid-1,2 anhydride) and diethanolamine synthesized hyperbranched poly(amide-ester) (hyperbranched polymer generation number is five generations) DMF solution input amount is changed into 50mL, other conditions are constant, obtained black powder The graft modification of hyperbranched poly(amide-ester) carbon nanotubes.

[0033] The obtained result product has some changes in the content of N element (9.7%) and O element (0.62% becomes 14.3%) relative to the result of the product of Example 2 in elemental analysis, and the peaks of amido and carboxyl in the XPS analysis results are also different from the spectrum of the embodiment Greater increase, the result further proves the grafting effect of amine group and hyperbranched polymer, and the dispersion performance of the modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com