Magnesium amide nano-particle hydrogen storage material and preparation thereof

A nanoparticle and ammonia technology, which is applied in the field of preparation of metal amide compounds, can solve problems such as Mg that cannot be prepared as single crystals, achieve excellent hydrogen absorption and desorption kinetic properties, high sample purity, and improve hydrogen absorption and desorption kinetic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, synthetic Mg (NH 2 ) 2 nanoparticles

[0016] (1) Put the magnesium block in the plasma arc heating furnace, after vacuuming, under 65%Ar / 35%NH with a total pressure of 0.9bar 3 (volume content) atmosphere, apply DC arc plasma to heat and evaporate magnesium and combine with NH 3 The reaction produces Mg 3 N 2 nanoparticles;

[0017] (2) the prepared Mg 3 N 2 Put the nanoparticles into the ammonia reaction furnace, heat the system to 325°C after vacuuming the system, pass through 4bar ammonia gas for 12 hours, and cool to room temperature to obtain Mg(NH 2 ) 2 particles. Embodiment 2, synthetic Mg (NH 2 ) 2 nanoparticles

Embodiment 2

[0017] (2) the prepared Mg 3 N 2 Put the nanoparticles into the ammonia reaction furnace, heat the system to 325°C after vacuuming the system, pass through 4bar ammonia gas for 12 hours, and cool to room temperature to obtain Mg(NH 2 ) 2 particles. Embodiment 2, synthetic Mg (NH 2 ) 2 nanoparticles

[0018] (1) Put the magnesium block in the plasma arc heating furnace, after vacuuming, under 40%N 2 / 60%NH 3 (Volume content) Under the mixed atmosphere, apply DC arc plasma to heat and evaporate magnesium and combine with NH 3 The reaction produces Mg 3 N 2 nanoparticles;

[0019] (2) the prepared Mg 3 N 2 Put the particles into a hydrogen reaction furnace. After the system is evacuated, 4 bar of ammonia gas is introduced, heated to 350°C, reacted for 6 hours, and cooled to room temperature to obtain Mg(NH 2 ) 2 particles.

Embodiment 3

[0020] Embodiment 3, synthetic Mg (NH 2 ) 2 nanoparticles

[0021] (1) Put the magnesium block in the hydrogen plasma electric arc heating furnace, after vacuuming, under the 30%Ar / 70%NH with a total pressure of 0.5bar 3 (Volume content) Under the mixed atmosphere, apply DC arc plasma to heat and evaporate magnesium and combine with NH 3 The reaction produces Mg 3 N 2 nanoparticles;

[0022] (2) the prepared Mg 3 N 2 Put the particles into a hydrogen reactor, heat the system to 250°C after evacuating the system, pass through 4bar ammonia gas for 20 hours, and cool to room temperature to obtain Mg(NH 2 ) 2 particles.

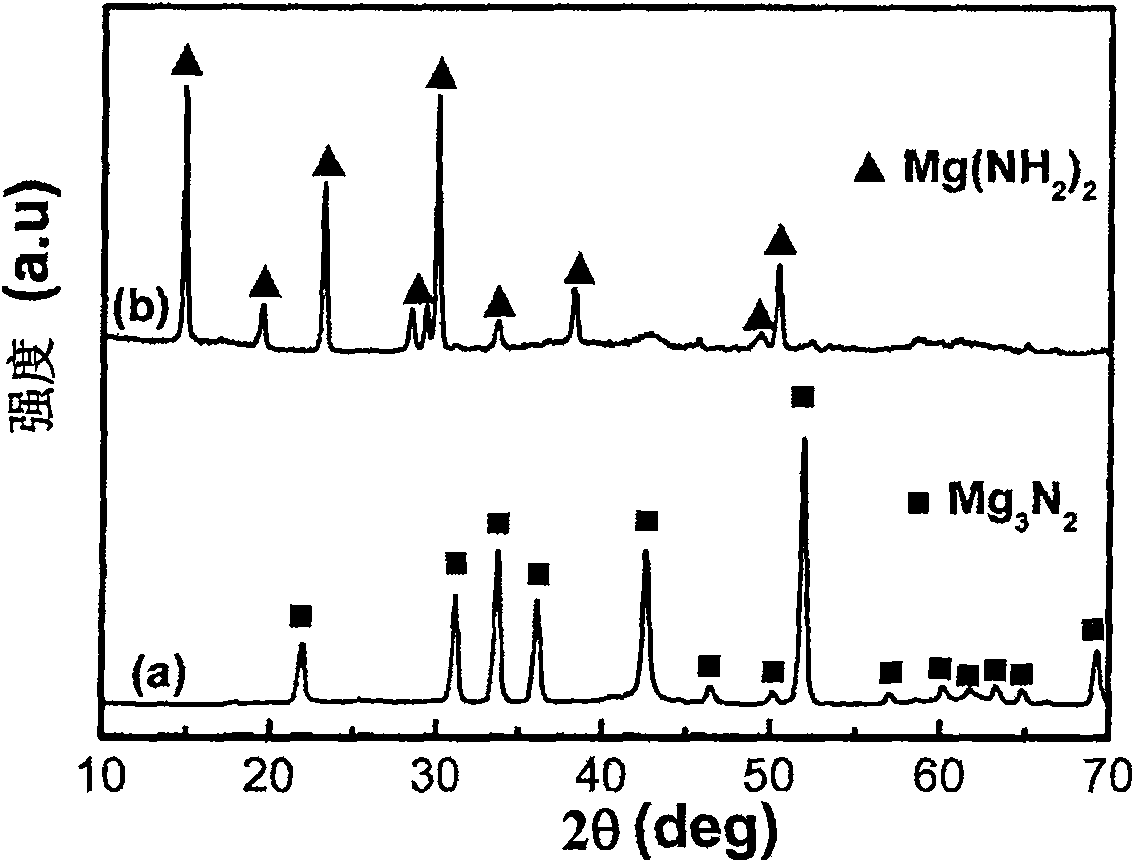

[0023] figure 1 Mg is the product of the above experiment 3 N 2 and Mg(NH 2 ) 2 The XRD (X-ray powder diffraction) figure, can clearly see that the prepared magnesium amido has a higher purity.

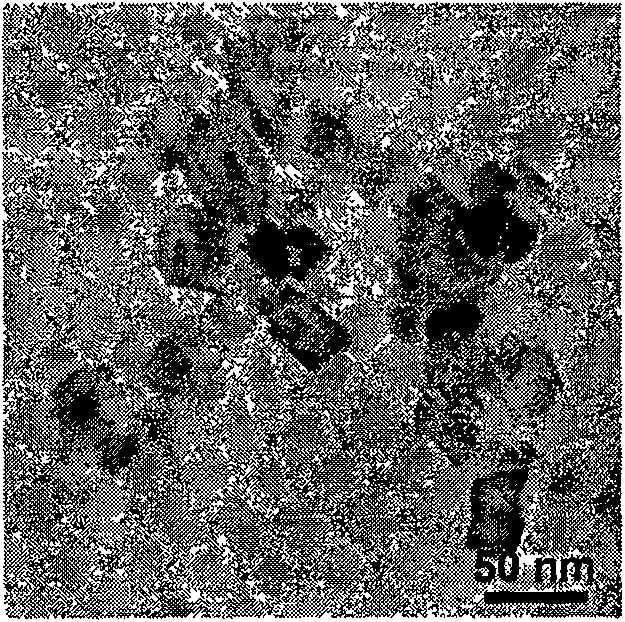

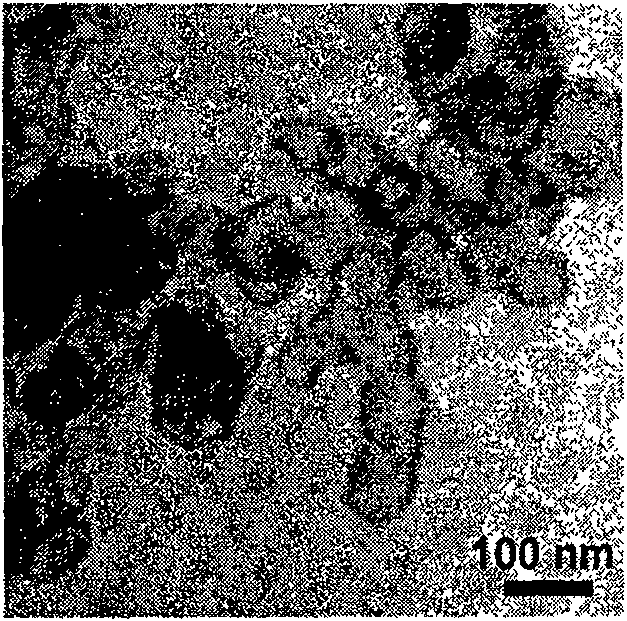

[0024] Figure 2a and 2b are the above experimental products Mg 3 N 2 and Mg(NH 2 ) 2 TEM (Transmission Electron Microscopy) image of nanoparticles, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com