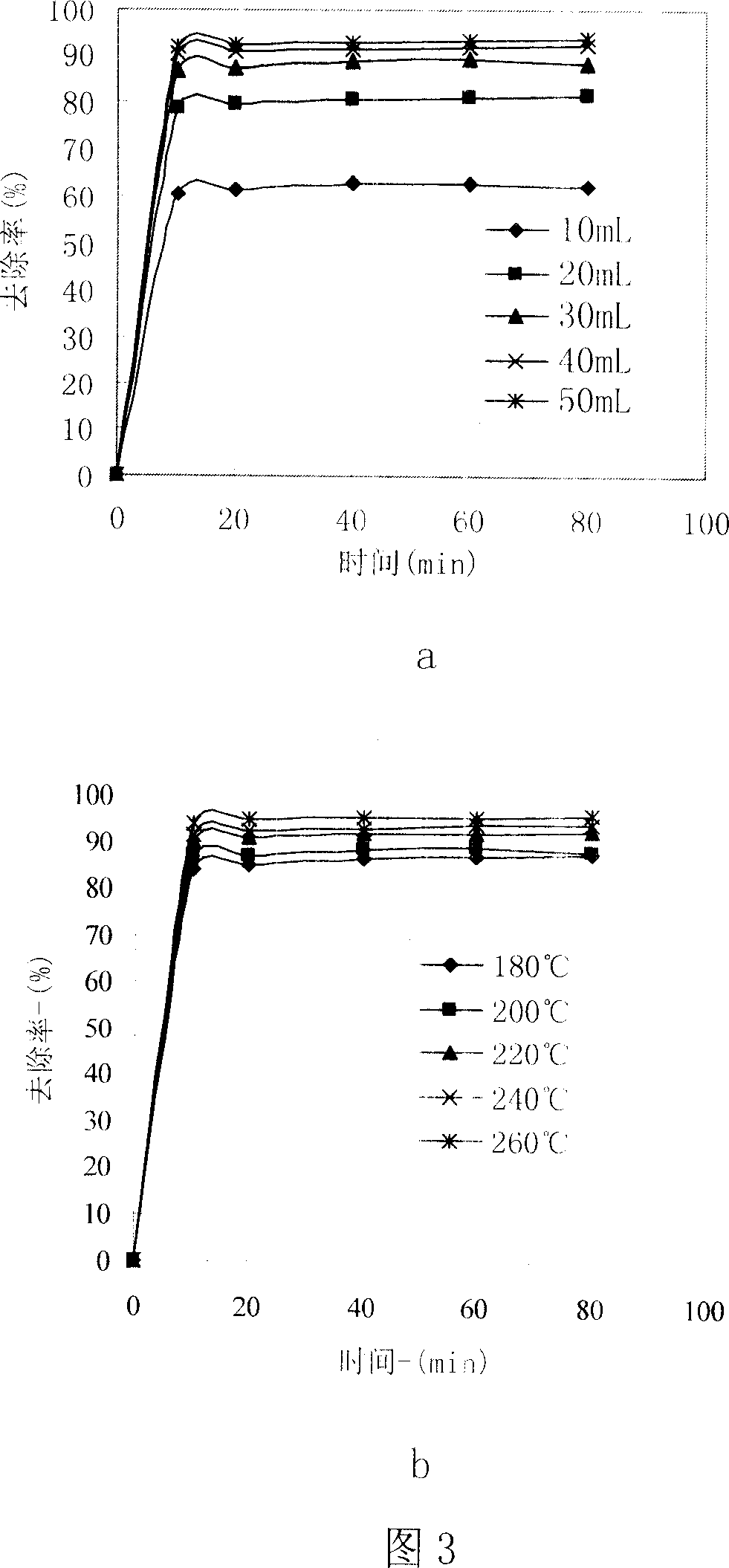

Method oxidation degradating m-nitrobenzene sodium sulfonate by catalytic wet method

A technology of sodium nitrobenzene sulfonate, catalytic wet oxidation, applied in chemical instruments and methods, oxidized water/sewage treatment, physical/chemical process catalysts, etc., can solve the problems of reduced hydrogen peroxide production cost and high treatment cost , to achieve high practicability and application value, high processing efficiency, and short time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

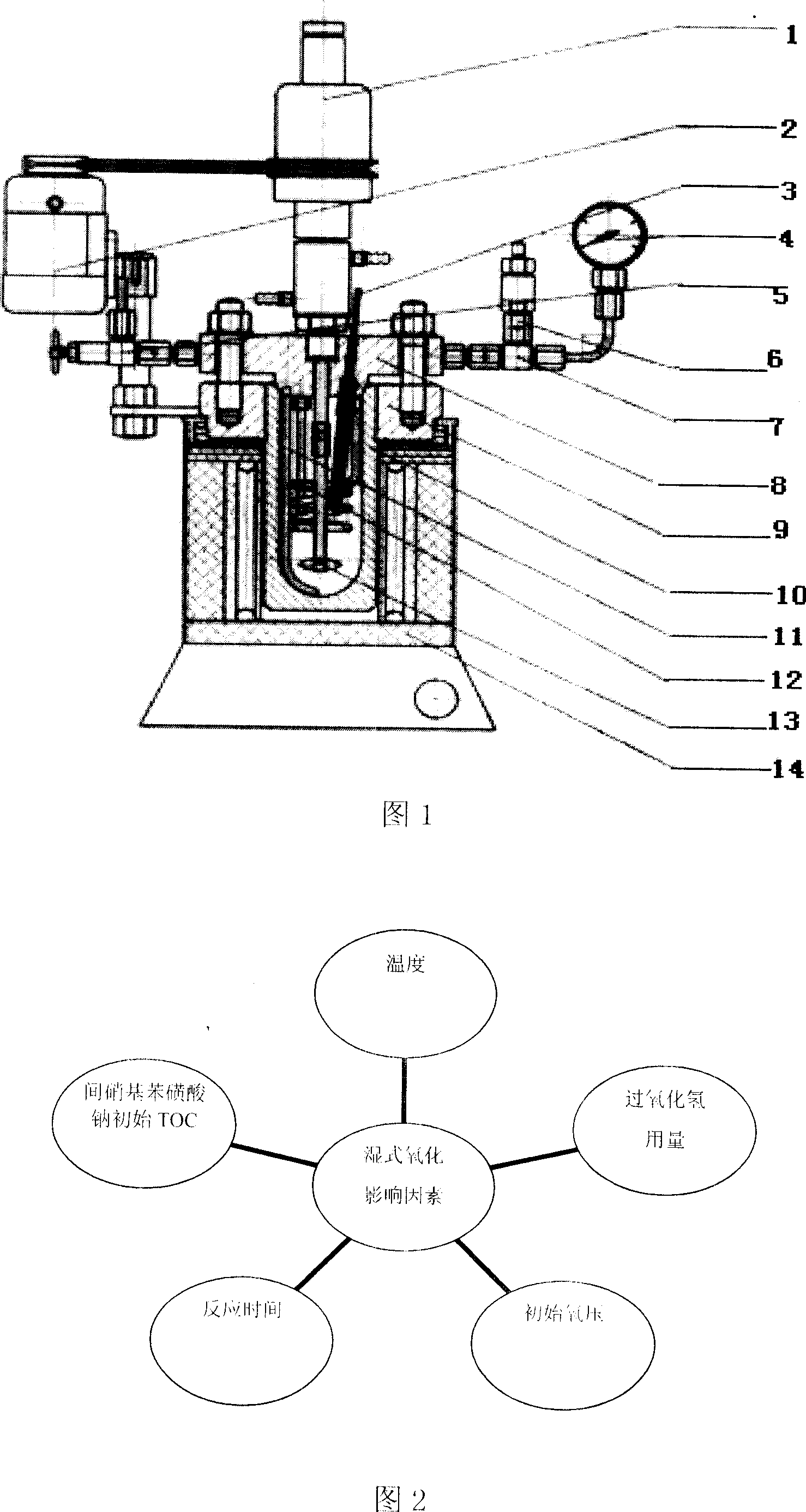

Method used

Image

Examples

Embodiment 1

[0040] Add 500 mL of sodium m-nitrobenzenesulfonate solution (initial TOC: 2560 mg / L) containing 1.0 g of copper nitrate and 25 mL of hydrogen peroxide into a 1 L reaction vessel, and seal it. Introduce 500mL of oxygen with an initial pressure of 1.0MPa, set the temperature at 180°C, stir, heat the reaction, take a sample after 1 hour of reaction, continue to heat up after sampling, and start timing when the temperature reaches 200°C, continue to react after 1 hour Sampling, reaction sampling at 220°C, 240°C, and 260°C in turn, using a total organic carbon analyzer (model TOC-V) produced by Shimadzu Corporation of Japan CPH ) to measure total organic carbon (TOC).

[0041] The measurement results are shown in the table:

[0042] Table 1 Sample treatment effect under different temperature conditions

[0043] temperature reflex

[0044] It can be seen from the above table that as the temperature increases and the time prolongs, the total organic carbon (TOC) of the ...

Embodiment 2

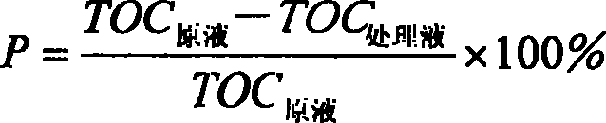

[0046] Add 500 mL of sodium m-nitrobenzenesulfonate solution (TOC: 2560 mg / L) containing 1.0 g of copper nitrate and 30 mL of hydrogen peroxide into the reaction kettle, and seal it. Introduce 500mL of oxygen with an initial pressure of 1.0MPa, set the temperature at 180°C, stir, heat and react, and take out the treatment liquid from the sampling valve at different time periods. The sampling time is set to 10 minutes, 20 minutes, 40 minutes, 60 minutes Minutes, 80 minutes, with a total organic carbon analyzer (model TOC-V) produced by Shimadzu Corporation of Japan CPH ) to measure total organic carbon (TOC). Change the reaction temperature to repeat the experiment, and select 200°C, 220°C, 240°C, 260°C to investigate the relationship between the removal rate and the reaction temperature. When the temperature is 180°C, the TOC removal rate is 87.26% after 80 minutes of reaction; when the temperature rises to 200°C, the TOC removal rate is 89.07% after 80 minutes of reaction; a...

Embodiment 3

[0049] Add 500 mL of sodium m-nitrobenzenesulfonate solution (TOC: 2560 mg / L) containing 1.0 g of copper nitrate and 30 mL of hydrogen peroxide into the reaction kettle, and seal it. Introduce 500mL of oxygen with an initial pressure of 1.0MPa, set the temperature at 200°C, stir, heat and react, and take out the treatment liquid from the sampling valve at different time periods, and set the sampling time as 10 minutes, 20 minutes, 40 minutes, 60 minutes Minutes, 80 minutes, with a total organic carbon analyzer (model TOC-V) produced by Shimadzu Corporation of Japan CPH ) to measure total organic carbon (TOC). Change the consumption of reaction copper nitrate catalyst, be selected as 0.5g, 1.5g, 2.0g, 3.0g. Investigate the relationship between removal rate and catalyst dosage. After 80 minutes of reaction, when no catalyst was added, the corresponding catalytic wet oxidation process removed m-nitrobenzene sulfonate with a removal rate of 86.23%; when adding 0.5 gram of cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com