Membrane electrode of protone exchange membrane fuel cell and preparation method thereof

A proton exchange membrane and fuel cell technology, which is applied to fuel cell parts, fuel cells, battery electrodes, etc., can solve the problem of increasing the contact resistance of membrane electrodes, reducing the time stability of membrane electrodes, affecting the electrochemical performance of fuel cells and Life and other issues, to achieve the effect of ensuring timely discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

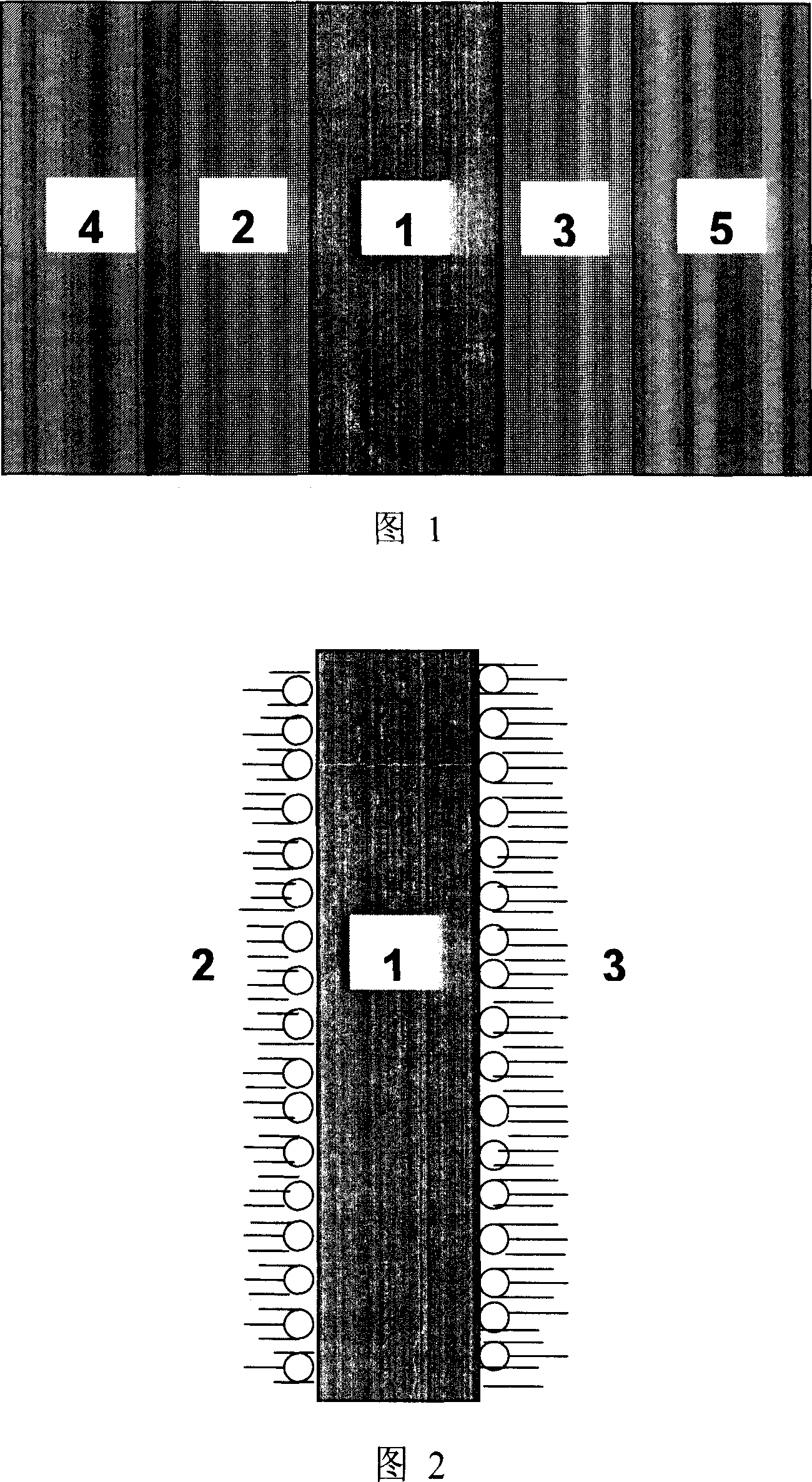

Image

Examples

Embodiment 1

[0030] (1) At 200°C, dissolve CHF1000 resin into N,N-dimethylformamide to obtain a resin solution with a concentration of 5wt%, and then put 1 part of carbon-supported Pt catalyst into 100 parts of the resin solution , mixed evenly to make a catalyst slurry, wherein the Pt content in the carbon-supported Pt catalyst is 20wt%, the catalyst slurry is sprayed, compounded on both sides of the CHFM1150 membrane, dried at 80 ° C for 60 minutes, and then flattened The catalyst slurry was coated on both sides of the CHFM1150 membrane, and the total loading of the catalyst Pt on the CHFM1150 membrane was 1.0 mg / cm 2 , to obtain a CHFM1150 film coated with catalyst slurry;

[0031] (2) Shorten the activated carbon fiber filaments with a diameter of 50-100 microns so that the length of the activated carbon fibers is between 0.01-5 mm to obtain carbon fibers; respectively place the CHFM1150 film and carbon fiber coated with catalyst slurry in an electrostatic The receiving screen and the...

Embodiment 2

[0034] (1) At 200°C, dissolve the CHF1000 resin into a mixed solvent of water and N,N-dimethylformamide with a volume ratio of 1:5 to obtain a resin solution with a concentration of 5wt%, and then add 5 parts of carbon Load Pt catalyst into 100 parts of resin solution, mix uniformly to make catalyst slurry, wherein the Pt content in the carbon-supported Pt catalyst is 20wt%, the catalyst slurry is compounded on both sides of the CHFM1150 membrane by spraying, Dry at 80°C for 60 minutes, and then coat the catalyst slurry on both sides of the CHFM1150 membrane after leveling. The total loading of catalyst Pt on the CHFM1150 membrane is 1.0mg / cm 2 , to obtain a CHFM1150 film coated with catalyst slurry;

[0035] (2) Shorten graphite carbon fiber filaments with a diameter between 50 and 100 microns, so that the length of graphite carbon fibers is between 0.01 and 5 mm to obtain carbon fibers; respectively place the CHFM1150 film and carbon fiber coated with catalyst slurry in an e...

Embodiment 3

[0038] (1) At 200°C, CHF1000 resin is dissolved in N, N-dimethylacetamide to obtain a resin solution with a concentration of 5 wt%, and then 200 parts of carbon-supported Pt catalysts are dropped into 100 parts of the resin solution , mixed evenly to make a catalyst slurry, wherein the Pt content in the carbon-supported Pt catalyst is 40wt%, the catalyst slurry is sprayed, compounded on both sides of the CHFM10125 film, dried at 80 ° C for 60 minutes, and then flattened The catalyst slurry was coated on both sides of the CHFM10125 membrane, and the total loading of the catalyst Pt on the CHFM10125 membrane was 1.0 mg / cm 2 , to obtain the CHFM10125 proton exchange membrane coated with catalyst slurry;

[0039] (2) Shorten the activated carbon fiber filaments with a diameter of 50-100 microns so that the length of the activated carbon fibers is between 0.01-5 mm to obtain carbon fibers; respectively place the CHFM10125 film and carbon fiber coated with catalyst slurry in an elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com