Solution raw material for organic metal chemical vapor deposition and complex oxide dielectric thin film formed by using such raw mataerial

A chemical vapor deposition and organometallic technology, which is applied in metal material coating process, gaseous chemical plating, circuit, etc., can solve problems such as troublesome film preparation, reduced film forming stability, and unstable coordination compounds, etc., and achieves excellent results. Effects of Gradient Coverage and High Film Formation Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] First, prepare Pb(dpm) separately 2 As an organic Pb compound, Zr(dmhd) was prepared 4 As an organic Zr compound, Ti(O-i-Pr) was prepared 2 (dpm) 2 as an organic Ti compound. Wherein, dmhd represents 2,6-dimethyl-3,5-heptanedione residue, and O-i-Pr represents isopropoxide. The above Pb(dpm) 2 , Zr(dmhd) 4 and Ti(O-i-Pr) 2 (dpm) 2 mixed so that it forms the predetermined Pb 1.15 (Zr 0.45 Ti 0.55 )O 3 The composition ratios were dissolved in the organic solvents shown in Tables 1 to 3 below to prepare 0.3 mol / L solution raw materials No. 1 to No. 15-4, respectively. Also, prepare O 2 as an oxygen source.

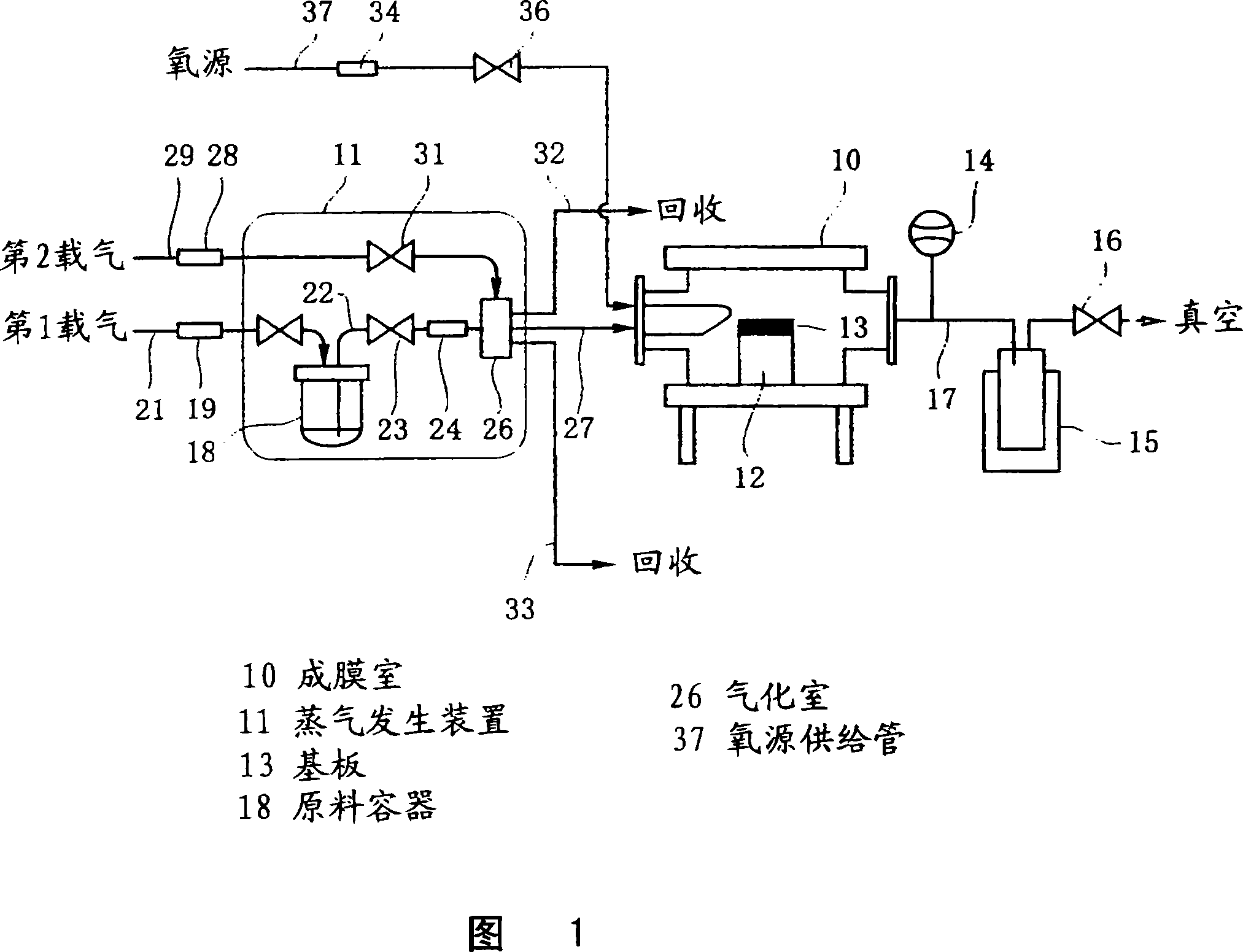

[0051] Then, prepare Pt(200nm) / Ti(20nm) / SiO 2 A (500 nm) / Si substrate was used as a substrate, and this substrate was set in the film formation chamber of the MOCVD apparatus shown in FIG. 1 . In addition, the prepared solution raw material is stored in the raw material container 18 . Then, the temperature of the substrate 13 was set at 600° C., the tem...

comparative test 1

[0055] In order to confirm whether the PZT dielectric thin films obtained in Example 1 and Comparative Example 1 have high remnant polarization, the following remnant polarization measurement and gradient coating test were performed on these films. The results are shown in Tables 1 to 3, respectively.

[0056] (1) Determination of residual polarization

[0057] On the film-formed substrate, the upper electrode was formed of 200 nm of Pt, and the residual polarization of the PZT dielectric thin film was measured using a ferroelectric detector (Ferroelectric Testeichi) (manufactured by Rajendontechnorochi Co., Ltd.; RT6000S).

[0058] (2) Gradient coverage test

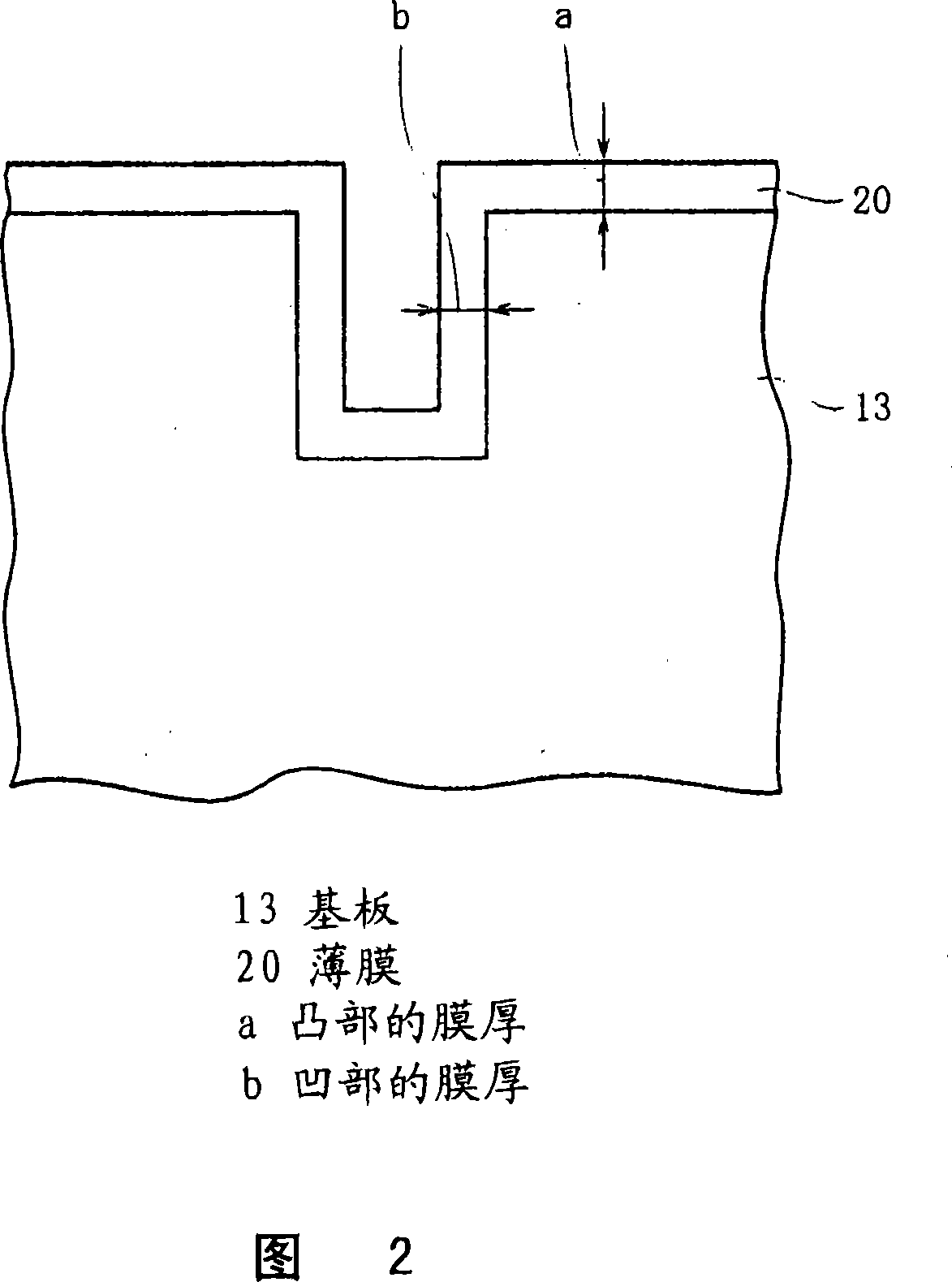

[0059] The gradient coverage of the PZT dielectric thin film on the film-formed substrate was measured from a cross-sectional SEM (Scanning Electron Microscope) image. The gradient coverage is represented by the numerical value of a / b when the thin film 20 is formed on the substrate 13 having steps such as grooves sho...

Embodiment 2

[0068] First, prepare Ba(dpm) separately 2 Prepare Sr(dpm) as an organic Ba compound 2 As an organic Sr compound, Ti(O-i-Pr) was prepared 2 (dpm) 2 as an organic Ti compound. Put the above Ba(dpm) 2 , Sr(dpm) 2 and Ti(O-i-Pr) 2 (dpm) 2 mixed to form a predetermined (Ba 0.7 St 0.3 )TiO 3 The composition ratios were dissolved in the organic solvents shown in Tables 4 to 6 below to prepare 0.3 mol / L solution raw materials No. 16 to No. 30-4, respectively. Also, prepare O 2 as an oxygen source.

[0069] Then, prepare Pt(200nm) / Ti(20nm) / SiO 2 A (500 nm) / Si substrate was used as a substrate, and this substrate was set in the film formation chamber of the MOCVD apparatus shown in FIG. 1 . In addition, the prepared solution raw material is stored in the raw material container 18 . Then, the temperature of the substrate 13 was set to 700° C., the temperature in the vaporization chamber 26 was set to 250° C., and the pressure in the film formation chamber 10 was set to abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com