Method for producing biodiesel oil and soil regulator using plant waste

A technology of plant waste and soil conditioner, applied in the field of biodiesel and soil conditioner production, can solve the problems of no patents and no reports, and achieve the effects of improving soil physical and chemical properties, improving soil structure, and loosening soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

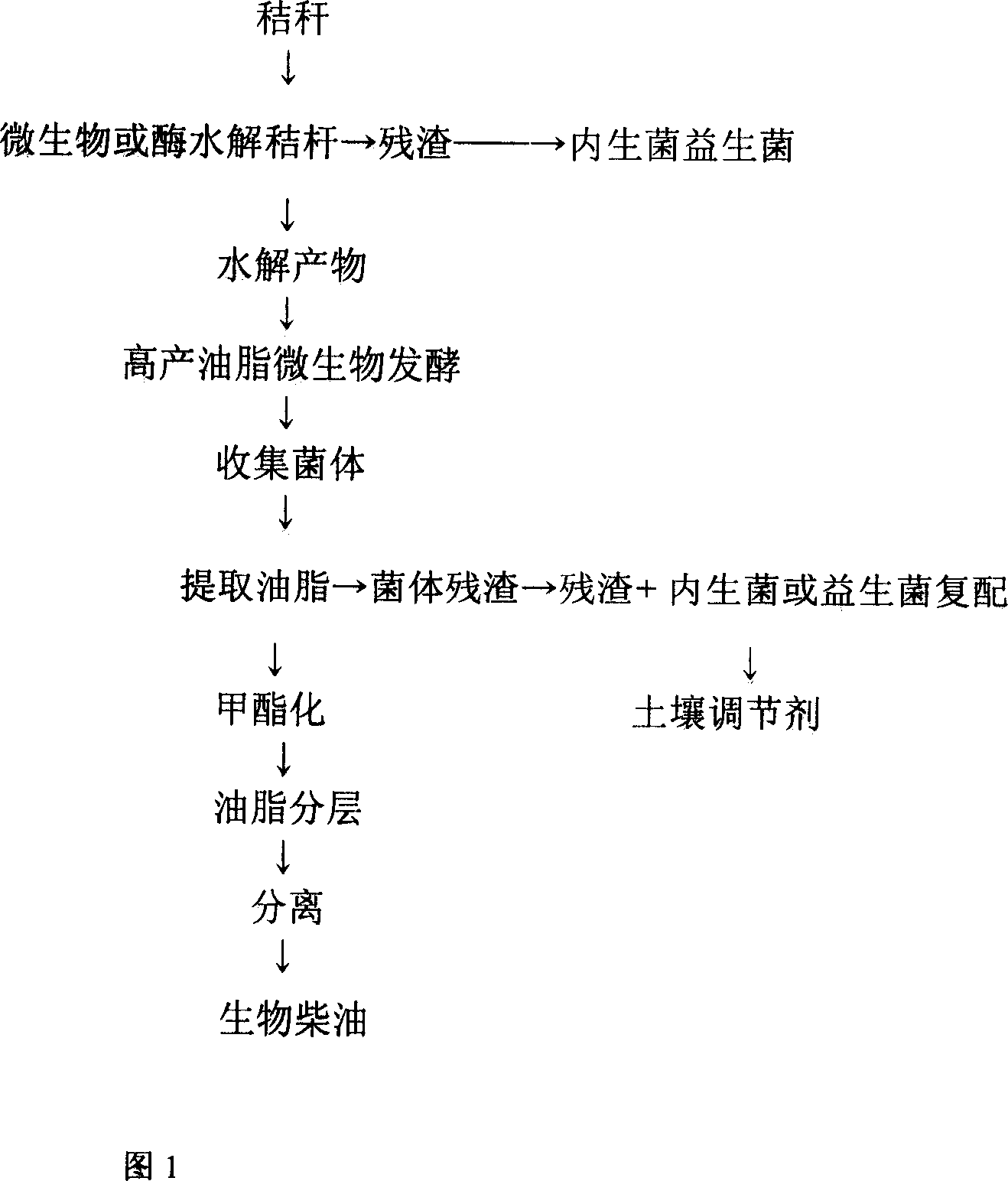

Image

Examples

Embodiment 1

[0031] The corn stalks were properly crushed, added with nutrients, cultured with Trichoderma reesei ATCC46480 at 25℃ for 3 days, added with Rhodotorula glutinis ATCC10659, cultivated for 3 days, harvested, and extracted with organic solvents Oils and fats undergo an exchange reaction with methanol under acid-base catalysis to produce fatty acid methyl esters (ie biodiesel). The solid waste of product production is inoculated with plant endophytes or probiotics (such as the probiotic Trichoderma koningii ATCC201709) Incubate at 20-25°C for 3 days. After mixing, the microbial content and nutrient content in the product are uniform, and it becomes a soil regulator, which is used to improve the soil organic matter, nitrogen fertilizer level, and increase the number of soil microorganisms.

Embodiment 2

[0033] After the rice straw is properly crushed, the straw is directly hydrolyzed with microbial cellulase, hemicellulase, lignin hydrolase, etc., and the hydrolyzate is sterilized by adding nutrients and inoculated with high oil-yielding Rhodotorula glutinosa ATCC10659, fermented for 3 days The yeast cells are harvested, the oil is extracted with an organic solvent, and the exchange reaction with methanol is carried out under acid-base catalysis to produce fatty acid methyl esters (ie, biodiesel). Enzymatically hydrolyzed solid wastes of straw were inoculated with plant endophytes (Phomopsis sp ATCC201398), cultivated at 25°C for 3 days, and the dried mycelium after yeast extraction was blended to become a soil regulator and used to improve soil organic matter , Nitrogen fertilizer level, increase the number of soil microorganisms.

Embodiment 3

[0035]The deciduous leaves or branches of the poplar are crushed and inoculated with plant endophytes that produce high cellulase, lignin hydrolase, and high oil production, such as Chaetomium thermophile ATCC58420 and Phomopsissp. Microorganisms such as ATCC201398, Pestalotiopsis sp (ATCC90291), solid fermentation for 10 days or liquid aeration and stirring fermentation for 5 days, organic solvent extracts oil, and exchange reaction with methanol under acid-base catalysis to produce fatty acid methyl esters (ie biodiesel) ). The solid waste was again inoculated with Phomatophora ATCC201398, Chaetomium ATCC58420 and Polychaeteia ATCC90291 and other strains, cultivated at 25°C for 3 days, and after blending, it became a soil regulator, used to improve soil organic matter, nitrogen fertilizer levels, and increase soil Number of microorganisms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com