Nitrogen-phosphor codoping titanium oxide multi-stage aperture photocatalysis material and method for making same

A catalytic material, titanium oxide technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of nano-crystal particle agglomeration and growth, and achieve simple preparation process and equipment, good industrialization The effect of production prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

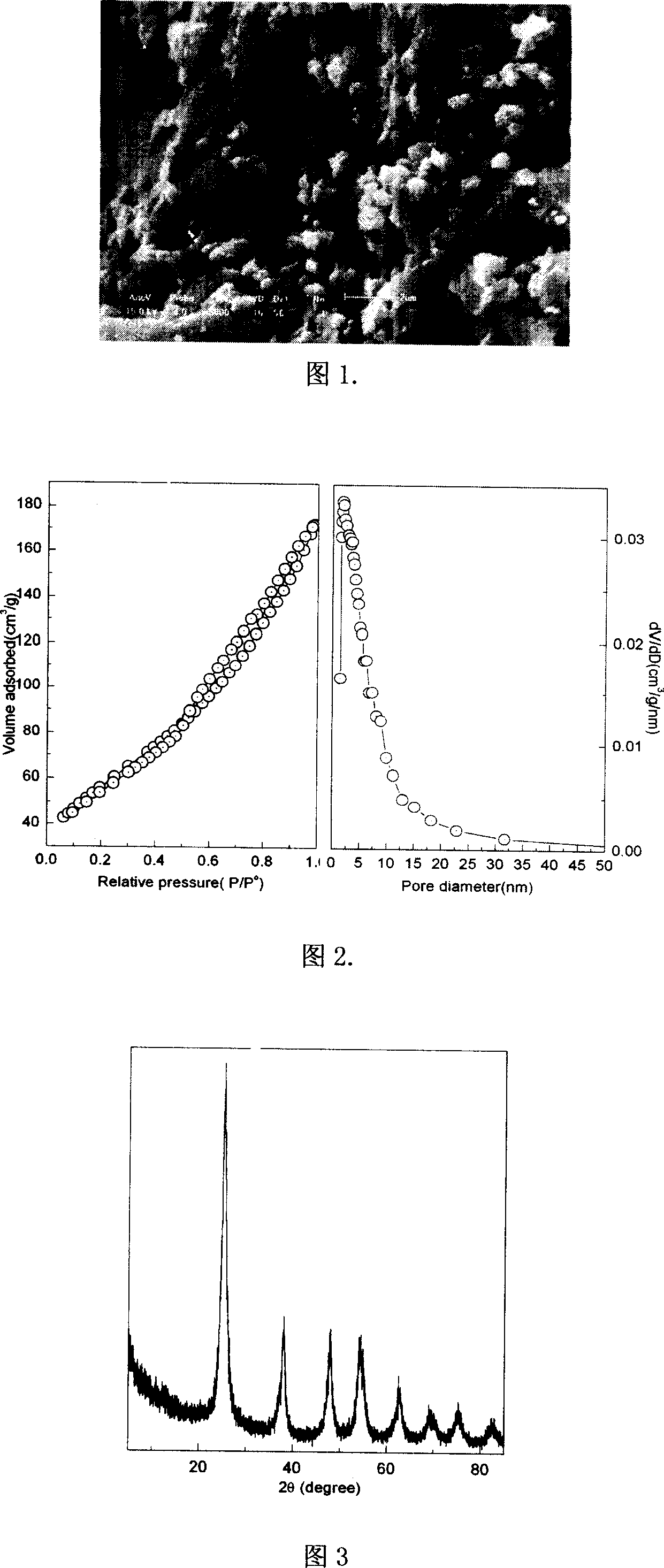

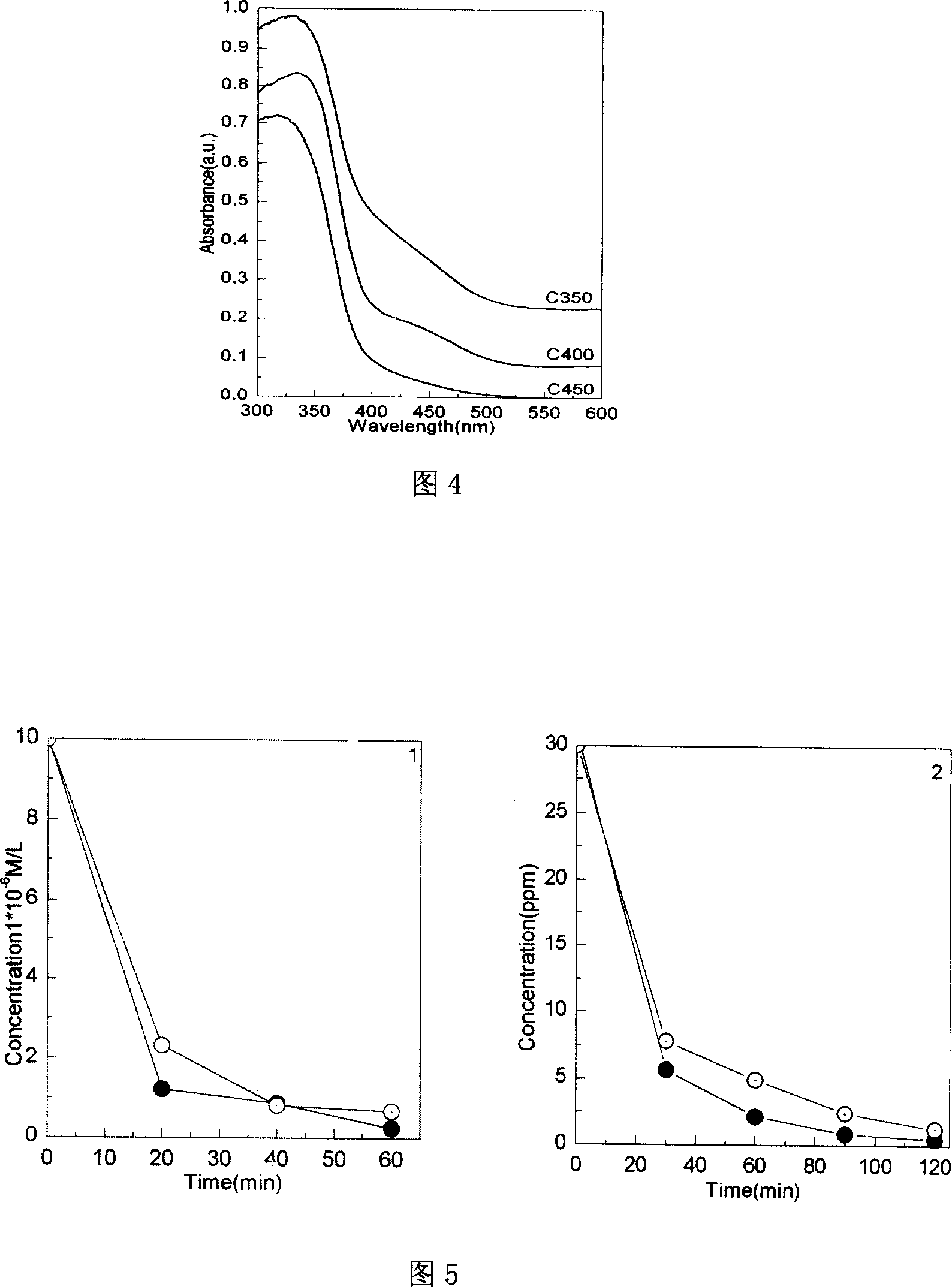

[0030] Add 8.7 g of butyl titanate and n-propanol (mass ratio: 28:1) into 30 ml of phosphoric acid solution (pH=2), stir for 2 hours, and then transfer to an 80-degree autoclave for aging for 48 hours, take it out, wash it, and dry it at 60°C. Obtain precursor powder. Weigh 2g of the precursor, add 5ml of urea aqueous solution (2mol / L), stir for three hours, age at room temperature for 24 hours, dry, and roast at 350, 400, 450°C for 2 hours in an air atmosphere, and the obtained light yellow-brown powder is nitrogen Phosphorus co-doped macroporous-mesoporous titania. Figure 1 is its scanning electron micrograph, showing that the sample has regularly arranged macropore channels of 0.5-2 μm. Figure 2 is the nitrogen adsorption-desorption isotherm and the corresponding pore size distribution diagram, the mesopore diameter is 0.21-0.35nm, and the specific surface is as high as 272m 2 / g. Figure 3 is its XRD spectrum, which shows titanium oxide in anatase phase. Elemental anal...

Embodiment 2

[0032] Add 8.7g of butyl titanate into 30ml of phosphoric acid solution (pH=2), stir for 2 hours, then transfer to an 80-degree autoclave for aging for 48 hours, take it out, wash with distilled water, and dry at 60°C to obtain a precursor powder . Weigh 2 g of the precursor, add 5 ml of urea aqueous solution (2 mol / L), stir for three hours, age at room temperature for 24 hours, dry, and roast at 350, 400, and 450 °C for 2 hours in an air atmosphere, and the obtained light yellow-brown powder is Nitrogen and phosphorus co-doped macroporous-mesoporous titania. The XRD spectrum shows that the sample is anatase phase titanium oxide. Nitrogen adsorption analysis shows that the mesopore diameter is 0.27-0.36nm, and the specific surface is as high as 261m 2 / g. Elemental analysis showed that the sample contained 1.12% nitrogen and 1.32% phosphorus. Fig. 4 is a UV-vis absorption spectrum, which shows that the absorption side band of the titanium oxide material is red-shifted to 4...

Embodiment 3

[0034] Mix 20ml of urea aqueous solution (2mol / L) and phosphoric acid solution (pH=2), add 34.8g of n-butyl titanate, stir for 2 hours, then transfer to a 60-degree autoclave for aging for 48 hours, after taking out It was washed and dried at 60°C. The obtained solid powder was calcined at 350-550° C. for 6 hours in an air atmosphere to obtain a light yellow-brown powder sample, which is a titanium oxide material co-doped with nitrogen and phosphorus. The sample has macroporous channels regularly arranged around 2μm, the mesopore diameter is 2-5nm, and the specific surface is as high as 359m2 / g. Elemental analysis showed that the sample contained 1.5% nitrogen and 3.2% phosphorus.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore size | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com