Method of extracting gossypol acetate from cotton seed oil niger

A technology of cotton oil soapstock and gossypol acetate, which is applied in the separation/purification of carbonyl compounds, organic chemistry and other directions to achieve the effects of reducing pollution, small demand and reducing the pressure of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

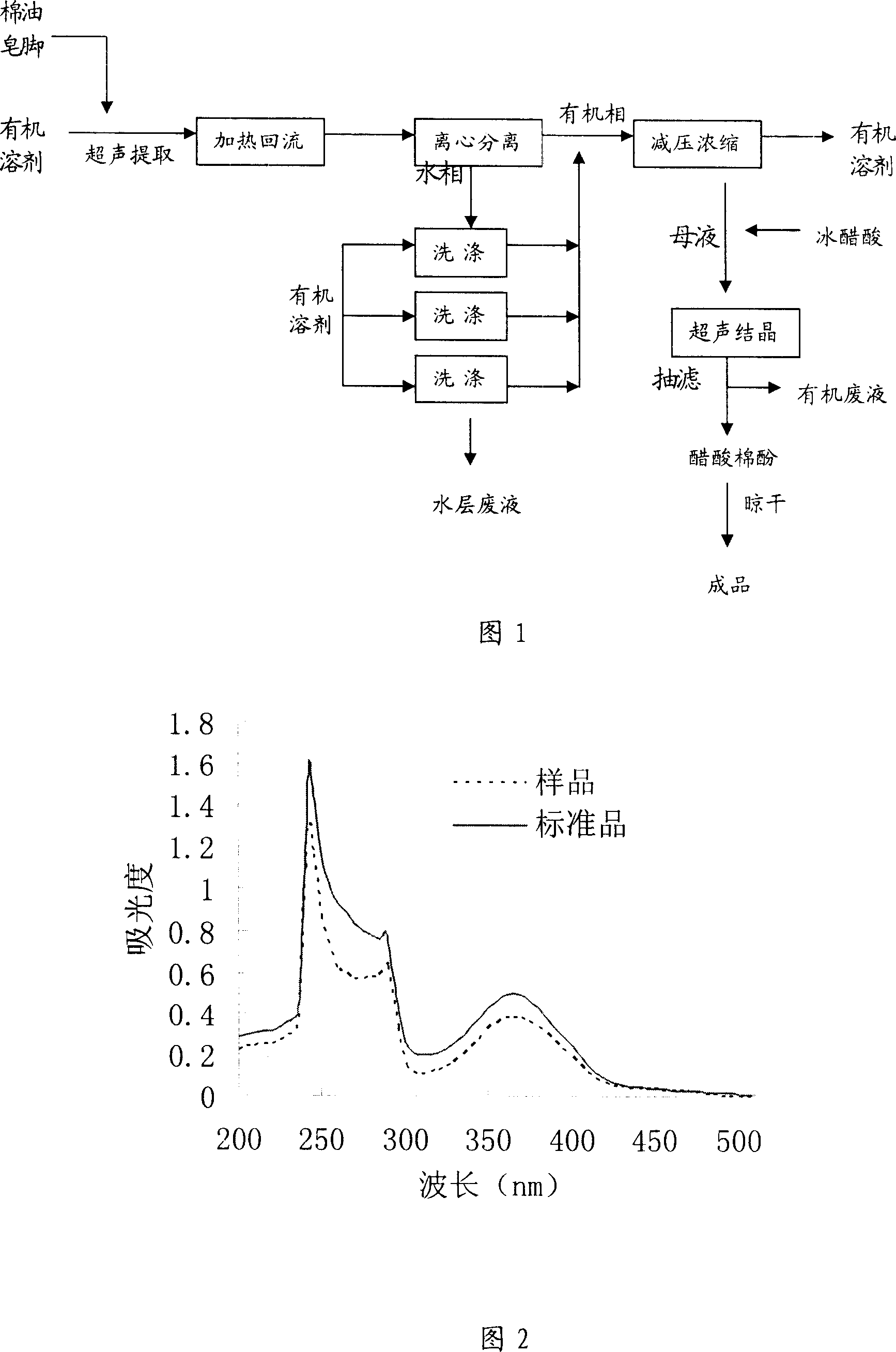

Method used

Image

Examples

Embodiment 1

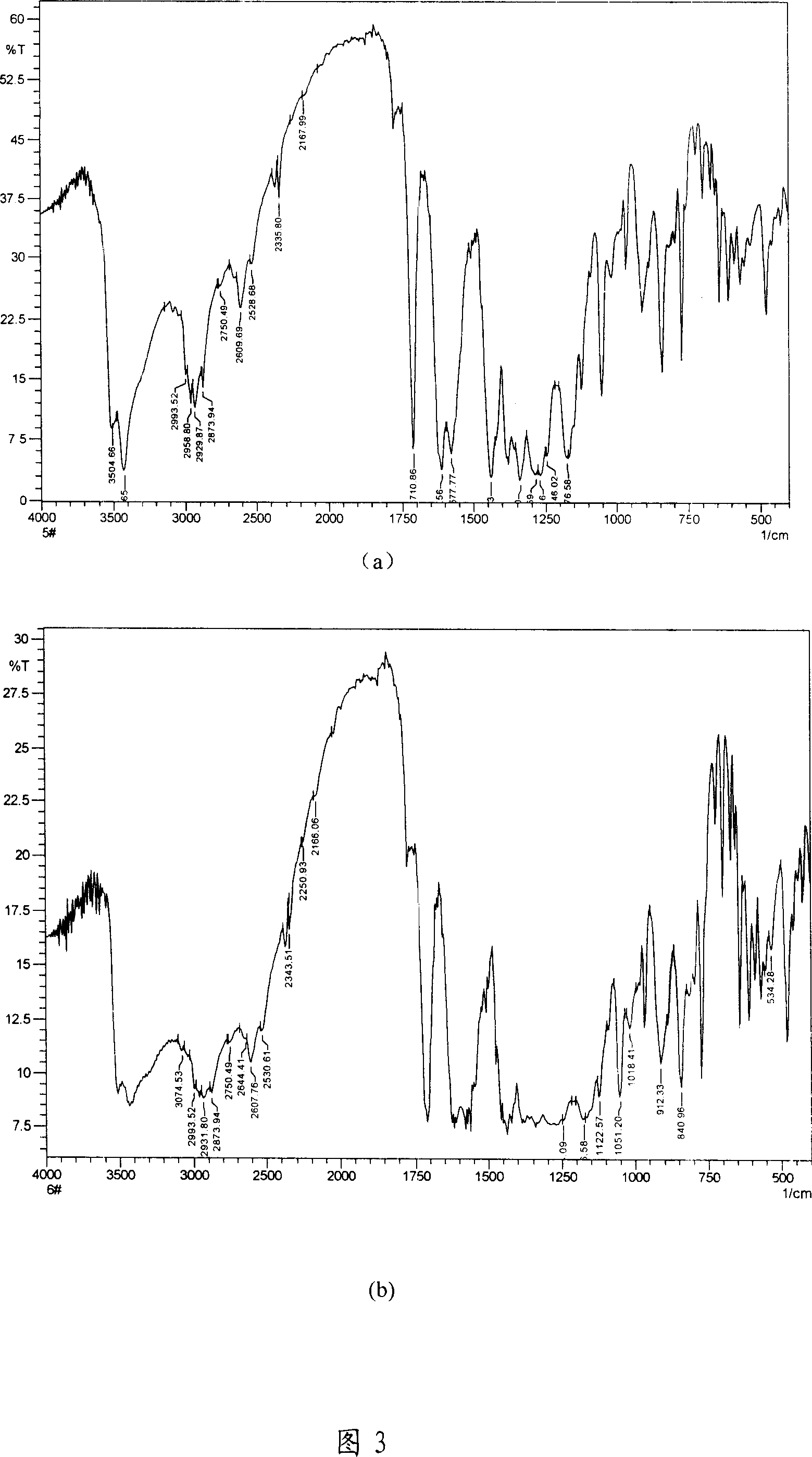

[0022] Weigh 100 grams of oil factory cotton oil soapstock with a balance and add it to 100 grams, adjust its acidity to 0.1mol.L with sulfuric acid -1 in methanol solution, stirred evenly, placed in ultrasonic extraction equipment with a power of 50W, ultrasonically extracted for 5 minutes, heated and refluxed in a water bath for 30 minutes, cooled to room temperature, centrifuged at 3000 rpm for 20 minutes, and washed with 2 times Wash the aqueous phase three times with methanol in the volume of the cooling liquid, collect the organic phase, and concentrate to the original 1 / 3 volume in a rotary evaporator at a vacuum of 0.08Mpa, then add 1 / 6 volume of glacial acetic acid to the concentrated solution, Simultaneously in the ultrasonic equipment of 100W, induced crystallization 3 minutes, after decompression suction filtration, normal hexane washing and drying, obtain 0.87 gram product, its infrared spectrogram and ultraviolet scan collection of illustrative plates are consiste...

Embodiment 2

[0024] Weigh 100 grams of protein factory cotton oil soap stock with a balance and add it to 500 grams, adjust its acidity to 0.5mol.L with phosphoric acid -1 In the ethanol solution, stir evenly, place in an ultrasonic extraction equipment with a power of 100W, after ultrasonic extraction for 10 minutes, heat and reflux in a water bath for 80 minutes, cool to room temperature, centrifuge at 3000 rpm for 20 minutes, and use 2 times Wash the aqueous phase three times with the ethanol volume of the cooling liquid, collect the organic phase, and concentrate it to the original 1 / 3 in the rotary evaporator under the vacuum degree of 0.08Mpa, then add 1 / 4 volume of glacial acetic acid to the concentrated solution, Simultaneously in the ultrasonic equipment of 100W, induced crystallization 5 minutes, after decompression suction filtration, normal hexane washing and drying, obtain 1.07 gram product, its infrared spectrogram and ultraviolet scanning collection of illustrative plates are...

Embodiment 3

[0026] Weigh 100 grams of oil factory cotton oil soap stock with a balance and add it to 1000 grams, adjust its acidity to 1.0mol.L with nitric acid -1Diethyl ether solution, stirred evenly, placed in ultrasonic extraction equipment with a power of 200W, ultrasonically extracted for 20 minutes, heated and refluxed in a water bath for 100 minutes, cooled to room temperature, centrifuged at 3000 rpm for 20 minutes, and washed with 2 times Wash the aqueous phase three times with diethyl ether in the volume of the cooling liquid, collect the organic phase, and concentrate it in a rotary evaporator under 0.08Mpa until the volume is 1 / 3 of the original volume, then add 1 / 3 of the volume of glacial acetic acid to the concentrated solution, Simultaneously, crystallization was induced in a 200W ultrasonic device for 8 minutes, and after vacuum filtration, n-hexane washing and drying, 0.94 g of product was obtained, and its infrared spectrum and ultraviolet scanning spectrum were consist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com