No-solvent electrically spinning process for preparing micron and nanometer fiber

A technology of micro-nano fiber and nano-fiber, applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problem of increasing the production cost of micro/nano fiber, the limitation of micro/nano fiber industrialization, and the absence of micro/nano fiber and other issues, to achieve the effect of easy promotion and application, easy operation and repetition, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

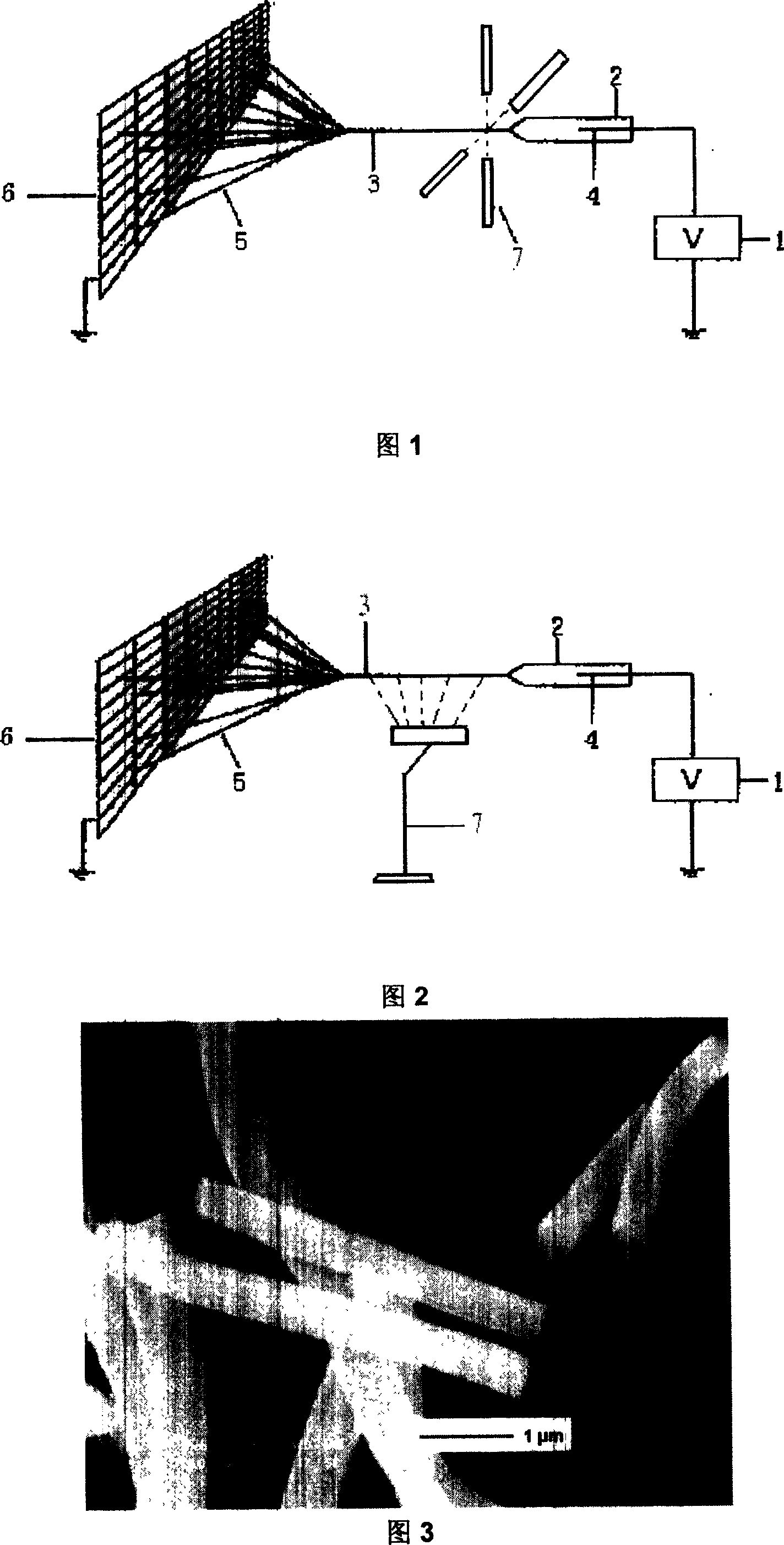

Method used

Image

Examples

Embodiment 1

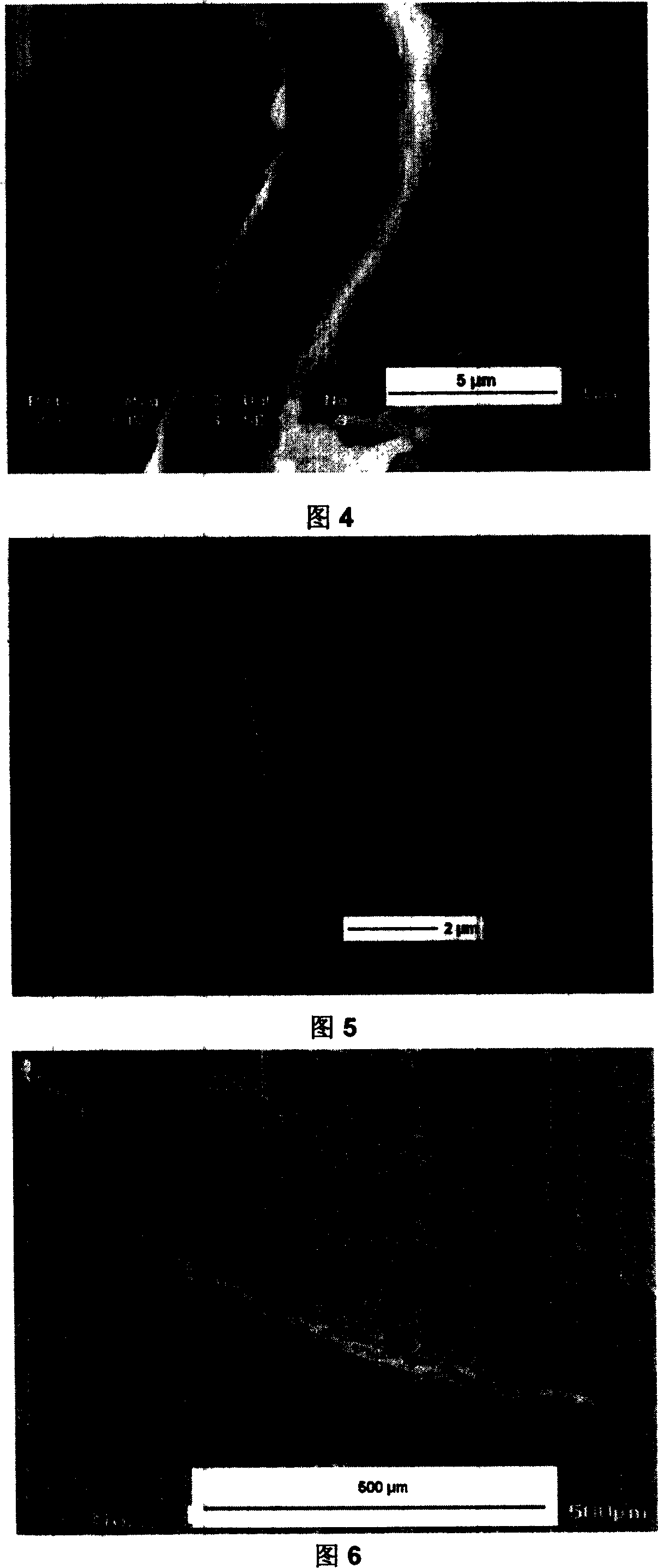

[0026] In a 20ml Erlenmeyer flask, add 0.07g of photoinitiator 1-hydroxy-cyclohexyl phenone (Gencure 184) to 2.19g of polyester acrylate (Gencure PEO 2257), cover it with black paper and place it at room temperature Stirred for 24 hours. Put the spinning solution into the spinneret, the inner diameter of the spinneret is 1mm, wrap the spinneret with black paper, then wrap it with aluminum foil, insert the copper electrode as the anode, and use the aluminum foil as the cathode to receive the product , the distance between the two pole plates is 45cm, and a 800mw / cm 2 The UV-LED point light source is applied at a voltage of 17kV for electrospinning, and at the same time, the UV-LED point light source is turned on for irradiation. After 10 minutes, short fibers with an average length of 4.5 μm and a diameter of 400 nm will be obtained on the aluminum foil.

Embodiment 2

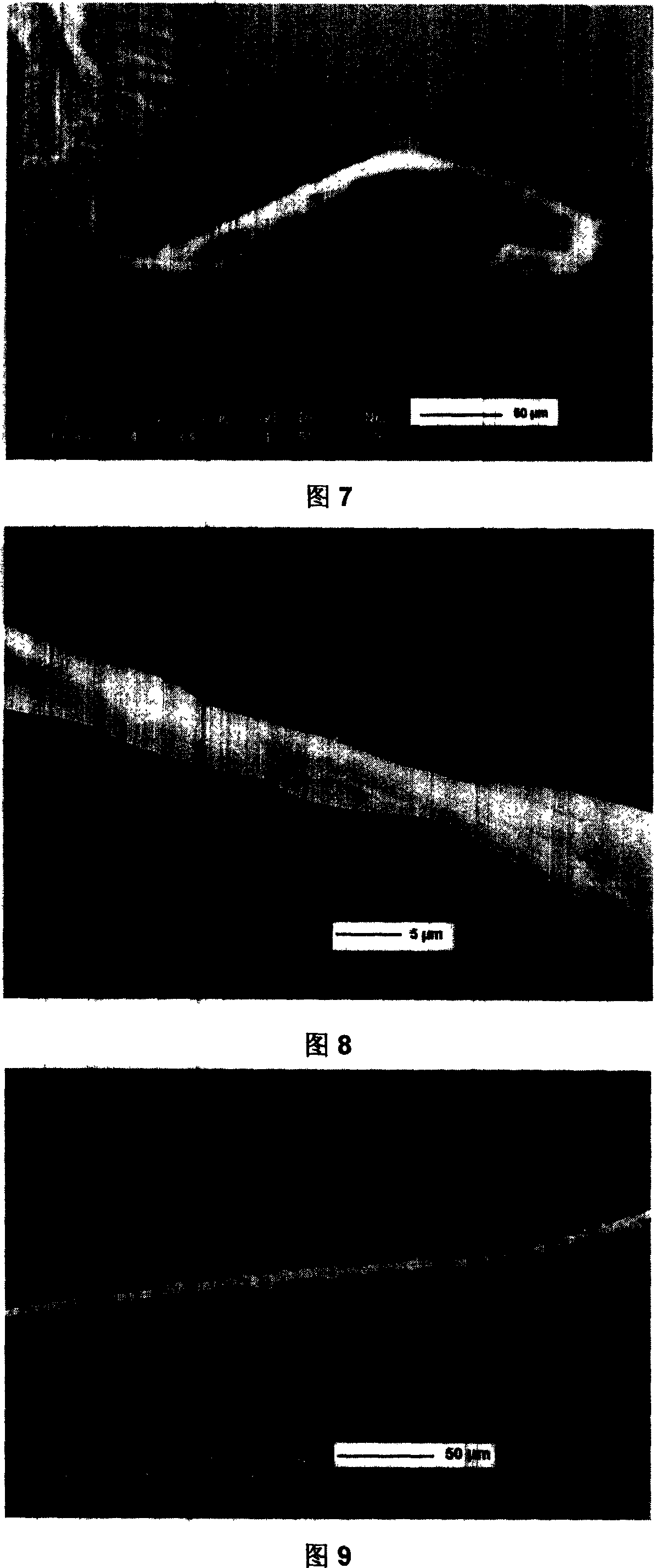

[0028] In a 20ml Erlenmeyer flask, add 0.07g photoinitiator 1-hydroxy-cyclohexyl phenone (Gencure 184) to 2.19g polyester acrylate (Gencure PEO 2257), cover it with black paper, at room temperature Stirred for 24 hours. Heat at 50°C for 2 hours, put the spinning solution into the spinneret, the inner diameter of the spinneret is 1mm, wrap the spinneret with black paper, then wrap it with aluminum foil, and insert the copper electrode as the anode. Use aluminum foil as the cathode to receive the product, the distance between the two plates is 45cm, place a PHILIPS 400W ultraviolet light source at a distance of 10cm from the spinneret and 45cm from the spinneret path, apply a voltage of 17kV, and turn on the PHILIPS 400W ultraviolet light source at the same time, after 10 minutes Finally, fibers with a diameter of 3 μm will be obtained on the aluminum foil.

Embodiment 3

[0030] In a 20ml Erlenmeyer flask, add 0.07g photoinitiator 1-hydroxy-cyclohexyl phenone (Gencure 184) to 2.19g polyester acrylate (Gencure PEO 2257), cover it with black paper, at room temperature Stirred for 24 hours. After heating at 50°C for 2 hours, after stirring at room temperature for 48 hours, put the spinning solution into the spinneret, the inner diameter of the spinneret is 1mm, wrap the spinneret with black paper, and wrap it with aluminum foil. On the package, a copper electrode is inserted as the anode, and an aluminum foil is used as the cathode to receive the product. The distance between the two pole plates is 45cm, and a PHILIPS 400W ultraviolet light source is placed at a distance of 10cm from the spinneret and 45cm from the spinneret path, and the applied voltage is 17kV. At the same time, the PHILIPS 400W ultraviolet light source is turned on. Fiber bundles with a diameter of approximately 200 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com