Preparation technical method of urine sulfur radical composite fertilizer

A technology of sulfur-based compound fertilizer and preparation process, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, inorganic fertilizer, etc., can solve the problems of difficult curing of products, low production cost, low phosphorus conversion rate, etc., and achieve easy caking, cost reduction, The effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

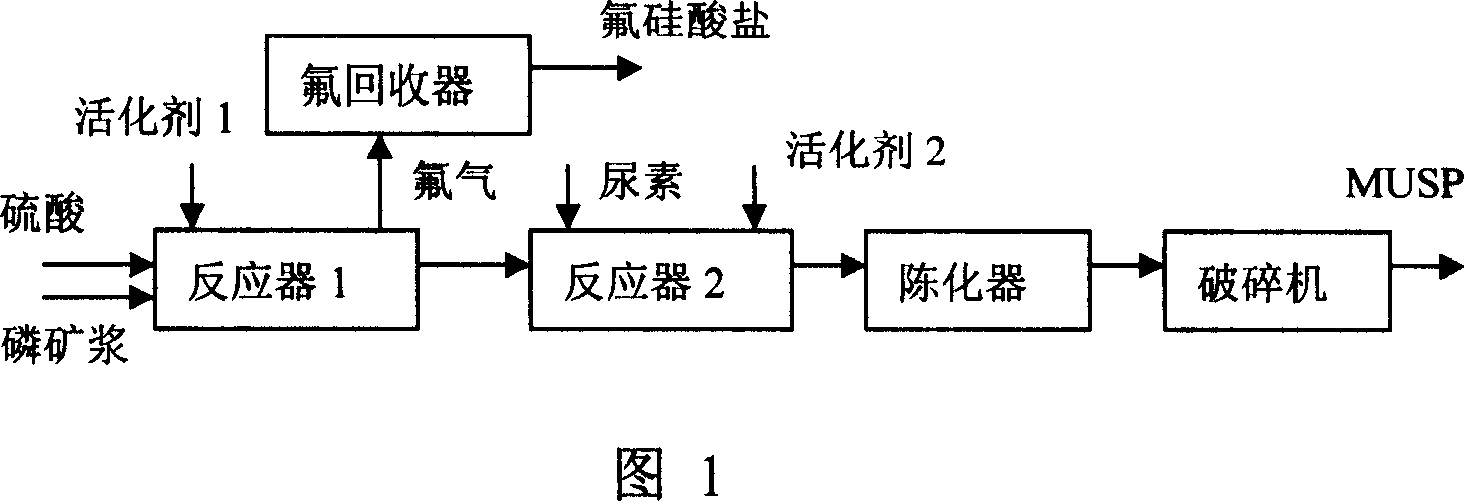

[0032] The process flow of this embodiment is shown in Figure 1. The raw material is phosphorite tailings obtained from Liaoning phosphorite ore after iron separation, P 2 o 5 It is about 30%. 100 parts of phosphate rock powder and 30 parts of water are prepared into phosphate rock slurry, and 40 parts of sulfuric acid with a concentration of 90% are added to acidolysis reactor 1 for acidolysis reaction, and 2 parts of activator dimethyl alkyl brominated agent are added, The reaction temperature is about 130° C., and the reaction time is about 30 minutes. The add-on of sulfuric acid all can be in the scope of 40~80 parts. The fluorine gas produced in the acidolysis reaction enters the fluorine recovery device, and fluorine is recovered in the form of fluorosilicate, and the acidolysis slurry after the reaction enters the conversion reactor 2, and 110 parts of urea are added at the same time to carry out the conversion reaction, and an activator is added 1 part of cationic ...

Embodiment 2

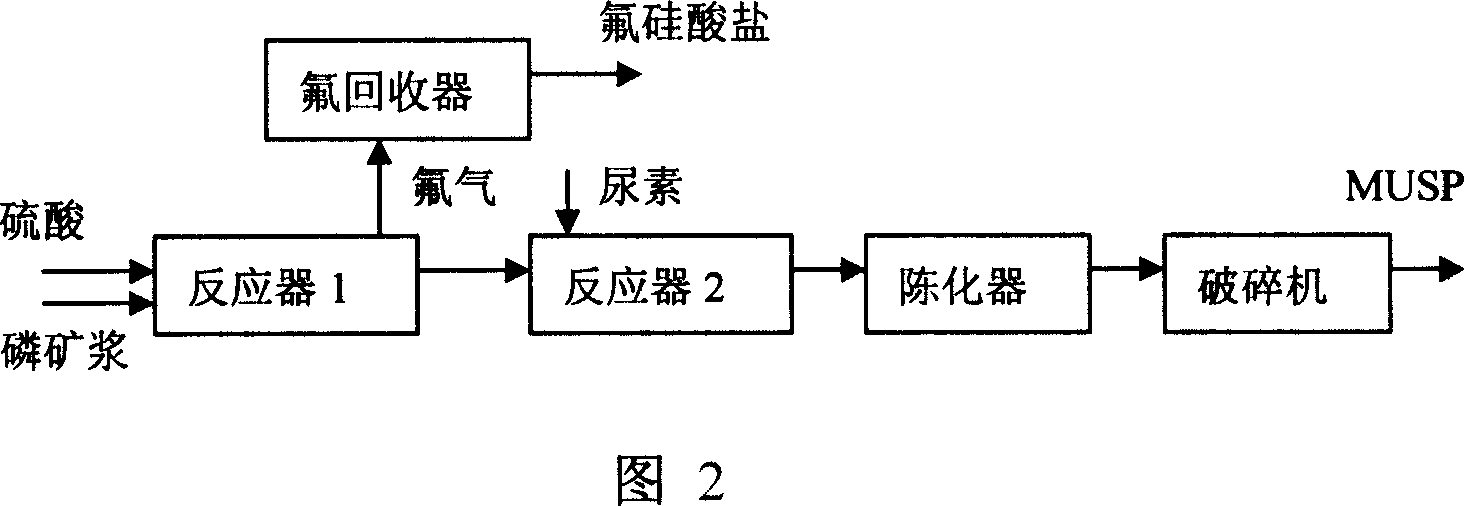

[0034] The process flow of this embodiment is shown in Figure 2. The raw material is still phosphorus tailings with a P2O5 content of about 30% obtained after iron separation from Liaoning phosphate iron ore. The process and process conditions of this embodiment are basically the same as in Example 1, except that the acidolysis reaction and conversion reaction do not add an activator to strengthen the reaction, the reaction time is longer, and the acidolysis reaction time is about 30 ~45 minutes, the conversion reaction time is about 45~60 minutes, and the aging time is about 17 hours, usually 16~20 hours. The conversion rate of phosphate rock is lower, and the conversion rate of phosphate rock in this embodiment is about 80%.

Embodiment 3

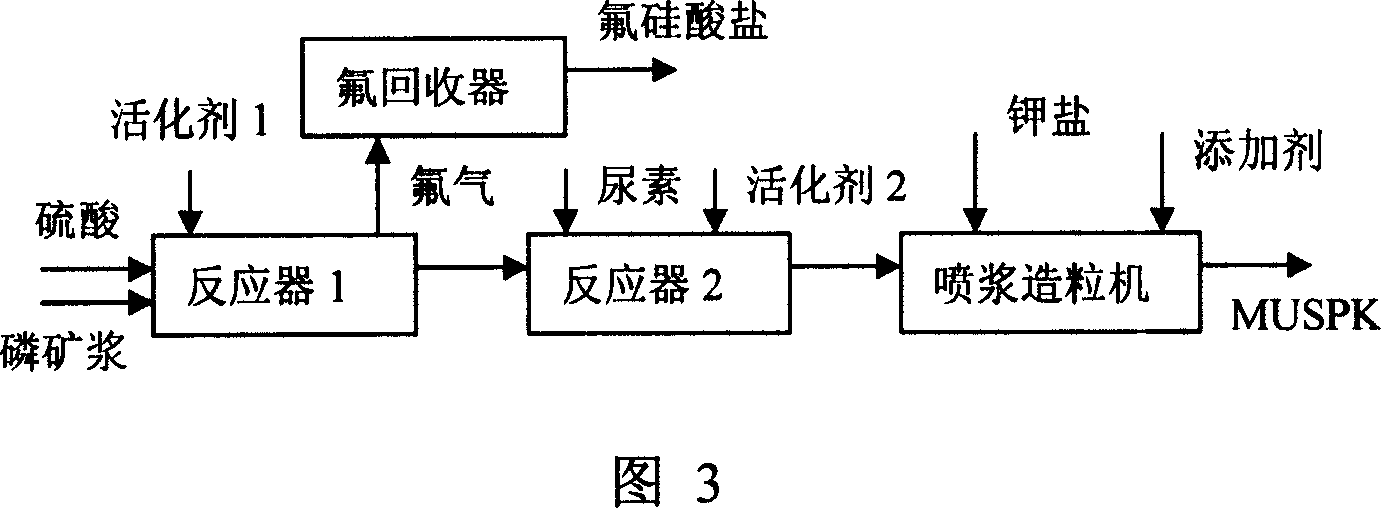

[0036] The process flow of this embodiment is shown in Figure 3. The raw material is P 2 o 5 Sichuan Jinhe Phosphate Mine with a content of 28%. 100 parts by weight of phosphate rock powder, 70 parts of water, 70 parts of sulfuric acid with a concentration of 98%, 2 parts of activator nitric acid, all materials are added to acid hydrolysis reactor 1 for acid hydrolysis reaction, the reaction temperature is about 100 °C, and the reaction time is about 20 minute. The add-on of sulfuric acid all can be in the scope of 30~70 parts. The fluorine gas produced in the acidolysis reaction enters the fluorine recovery device, and fluorine is recovered in the form of fluorosilicate. The acidolysis slurry after the reaction enters the conversion reactor 2, and 110 parts of urea are added at the same time, and the activator laurylamine polyoxygen Vinyl ether - 2 parts by weight of 12, the conversion reaction temperature is about 50°C, and the reaction time is about 45 minutes. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com