Elastic mud ground wal ceramic tile and manufacturing method

A mud floor and wall brick technology, applied in the field of elastic mud floor wall bricks and their manufacturing, can solve the problems of easy aging, low tensile strength, flammability, etc., and achieve the effects of not easy aging or deformation, and excellent weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

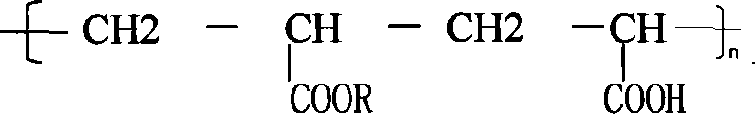

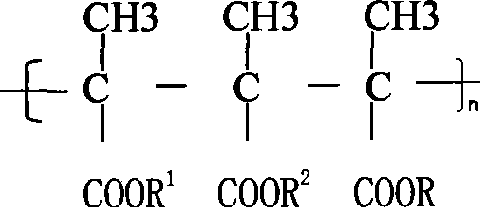

[0048] 70% yellow mud powder after drying, crushing and passing through 100-500 mesh sieve, 24.8% acrylic polymer copolymer emulsion, 0.2% benzylnaphthalenesulfonic acid formaldehyde condensate dispersant, silicone and fatty amine emulsion Softener 3%, toluenesulfonyl hydrazide foaming agent 2%, mechanically mixed to make it into a uniform composite mud; the mud is coated on the template with skin texture, the thickness of the coating is 2mm, and it is heated at 200 ° C ± 100 After drying at ℃, the mold was removed to obtain a yellow elastic clay floor and wall tile product with leather texture. If you need elastic mud floor tiles of other colors, add the corresponding color paste or color powder to the mud, and use the same method to make it. It is necessary to produce elastic mud floor wall tiles with different thicknesses, just increase or decrease the coating thickness. It is necessary to produce yellow elastic mud floor wall tiles with different surface patterns, just re...

Embodiment 2

[0050] Drying, crushing, 100-500 mesh sieve white mud powder 45%, polyethylacrylate, polybutylacrylate, methylolacrylamide copolymer 41.9%, water 3%, benzylnaphthalenesulfonic acid formaldehyde condensate Dispersant 0.1%, silicone and fatty amine emulsion softener 4%, azodicarboxamide foaming agent 4%, pigment printing color paste brown 2%, mechanically mixed to make it a uniform composite mud; The mud is coated on the formwork with antique brick patterns, the coating thickness is 6mm, and after drying at 200°C±100°C, the mold is released to obtain brown-yellow antique brick pattern elastic mud floor wall tiles. Antique brick pattern elastic mud floor wall tiles of other colors are required, and the corresponding color paste or color powder can be added to the mud, and the same method can be used. It is necessary to produce antique brick pattern elastic mud floor wall tiles of different thicknesses, just increase or decrease the coating thickness. It is necessary to produce b...

Embodiment 3

[0052] After drying, crushing, 37% of white mud powder through 100-500 mesh sieve, 50.9% of butyl acrylate (n-BA) and 2-ethylhexyl acrylate (octyl acrylate, 2-EHA) copolymer, benzyl 0.1% of naphthalenesulfonic acid formaldehyde condensate dispersant, 5% of silicone emulsion softener, 5% of azodicarbonamide (ADC) foaming agent, 1% of pigment printing paste black and red, mechanically mixed to make It becomes a uniform composite mud; the mud is coated on the formwork with wood grain, the coating thickness is 5mm, and after drying at 200°C±100°C, the mold is released to obtain a pink wood grain elastic mud floor wall tile product. If you need wood-grain elastic mud floor tiles of other colors, add the corresponding color paste or color powder to the mud, and use the same method to make it. It is necessary to produce wood-grain elastic mud floor wall tiles of different thicknesses, just increase or decrease the coating thickness. It is necessary to produce pink elastic mud floor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com