Method for preparing sol of high active Nano titanium dioxide

A nano-titanium dioxide, high-activity technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of low crystallization, high impurity content, low activity, etc., achieve reduced impurity content, simple process, sterilization and antibacterial and Effect of mildew prevention effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1. prepare titania sol with titanyl sulfate high pressure hydrothermal

[0032] Weigh titanyl sulfate, add water and stir until transparent, add dropwise sodium hydroxide to adjust the pH to more than 9, continue to stir for more than 2 hours, then repeatedly filter and wash until there is no sulfate ion (detected by titration with 0.5M barium chloride solution), Then wash repeatedly with distilled water until neutral. Finally, add water to the filter cake, mix it, beat it, then transfer the slurry to a constant temperature heating reactor with a double jacket, add water and mix it, then add acid solution dropwise to make the pH 1.2, and stir at room temperature for more than 2 hours. Then degumming is carried out, the slurry is heated and stirred at 75 °C, and a nano-titanium dioxide sol with a certain degree of crystallization is obtained after 24 hours; then it is transferred to a closed pressure-resistant reactor, and the pressure is controlled at 5×10 5...

Embodiment 2

[0033] Example 2. Purification and removal of impurities and pH adjustment of titanium dioxide sol prepared by high-pressure hydrothermal method

[0034] Weigh titanyl sulfate, add water and stir until transparent, add ammonia water dropwise to adjust the pH to more than 9, continue to stir for more than 2 hours, then repeatedly filter and wash until there is no sulfate ion (detected by titration with 0.5M barium chloride solution), and then Repeatedly wash with distilled water until neutral. Finally, add water to the filter cake, mix it, beat it, then transfer the slurry to a constant temperature heating reactor with a double jacket, add water and mix it, then add acid solution dropwise to make the pH 1.0, and stir at room temperature for more than 2 hours. Then degumming is carried out, the slurry is heated and stirred at 65 °C, and a nano-titanium dioxide sol with a certain degree of crystallization is obtained after 20 hours; then it is transferred to a closed pressure-res...

Embodiment 3

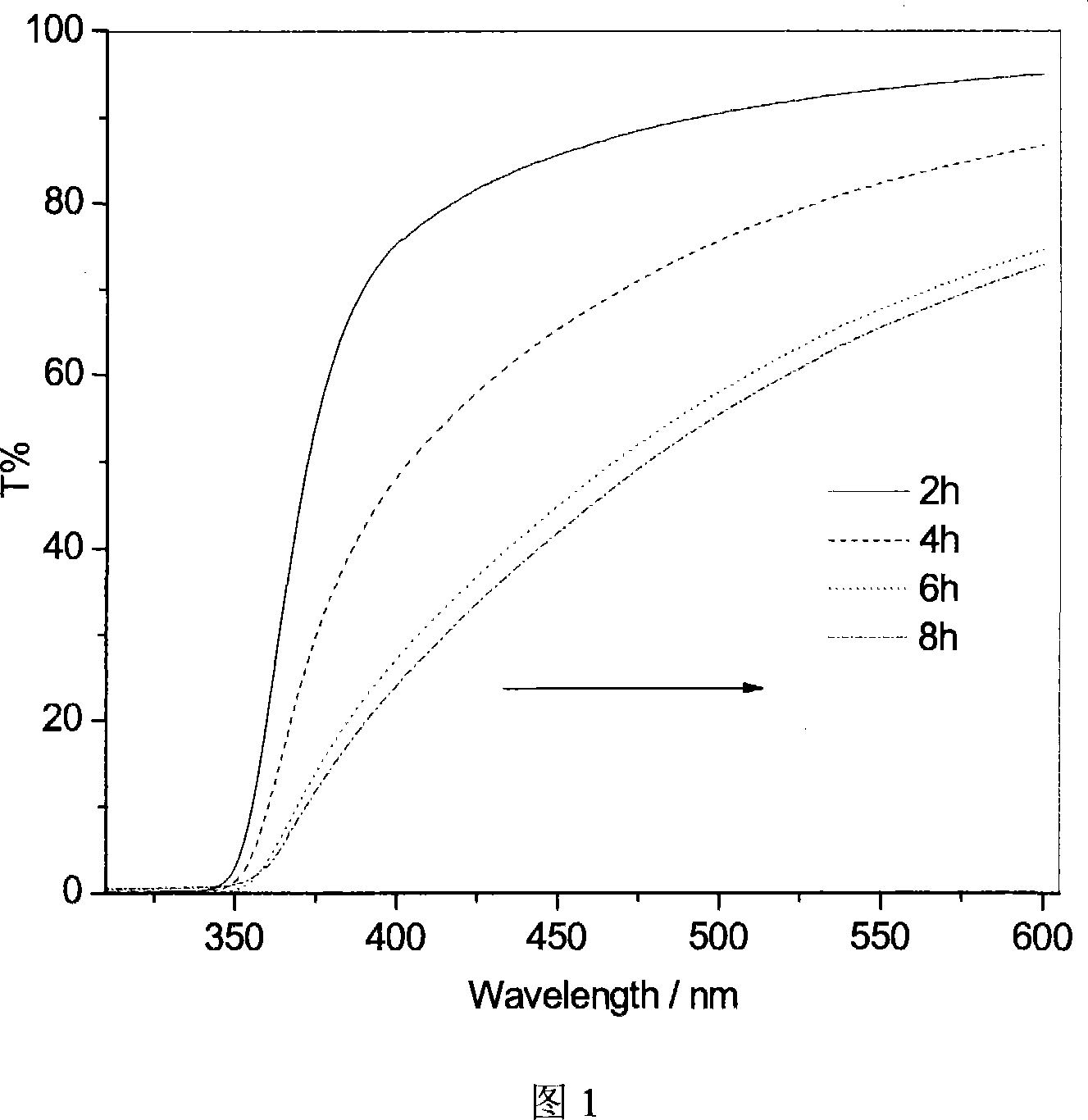

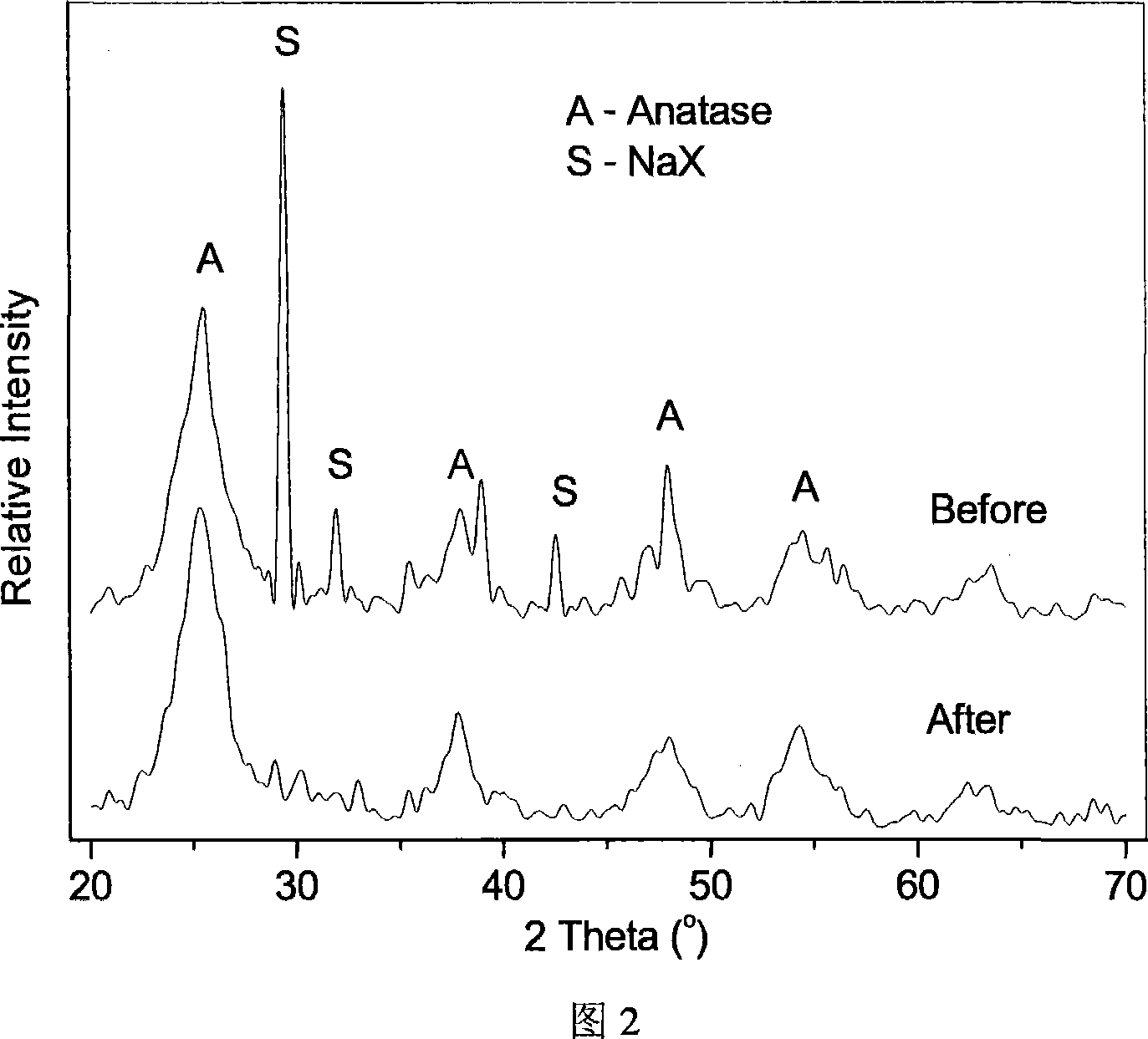

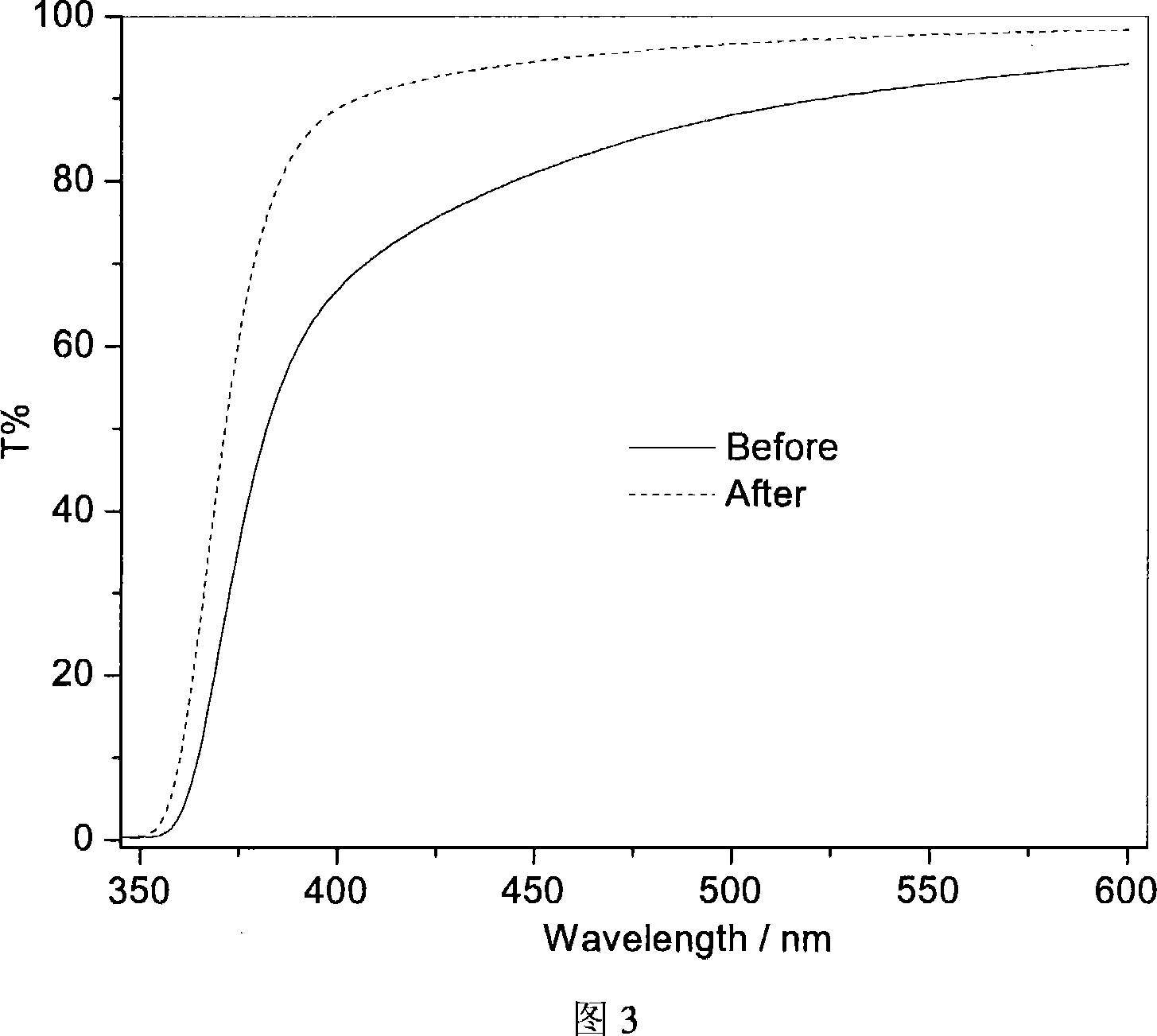

[0035] Embodiment 3. Spectral analysis and structural analysis of titanium dioxide sol before and after purification and impurity removal

[0036] In order to show the performance changes before and after the dialysis treatment in Example 2, we carried out XRD, UV-visible light transmittance spectrum and infrared (FTIR) tests on it. Figure 2 is the XRD spectrum of titania sol before and after dialysis. The results show that before dialysis, in addition to the diffraction peak of anatase, there are several very sharp diffraction peaks (as shown by S in the figure). Compared with the standard spectrum, it can be known that its by NaNO 3 、Na 2 SO 4 It is caused by the crystallization of sodium salt (NaX), which is caused by the debonding agent (nitric acid) and the residual impurities of raw materials in the preparation process. After dialysis (as shown in the figure After), the diffraction peaks of these impurities are greatly weakened or even disappeared, and the diffraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com