High-pureness high-density sintered tungsten oxide material

A technology of tungsten oxide and density, applied in the direction of tungsten oxide/tungsten hydroxide, etc., can solve the problems of difficult sintering and dense, low self-diffusion coefficient of pure tungsten trioxide, affecting performance and optoelectronic characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

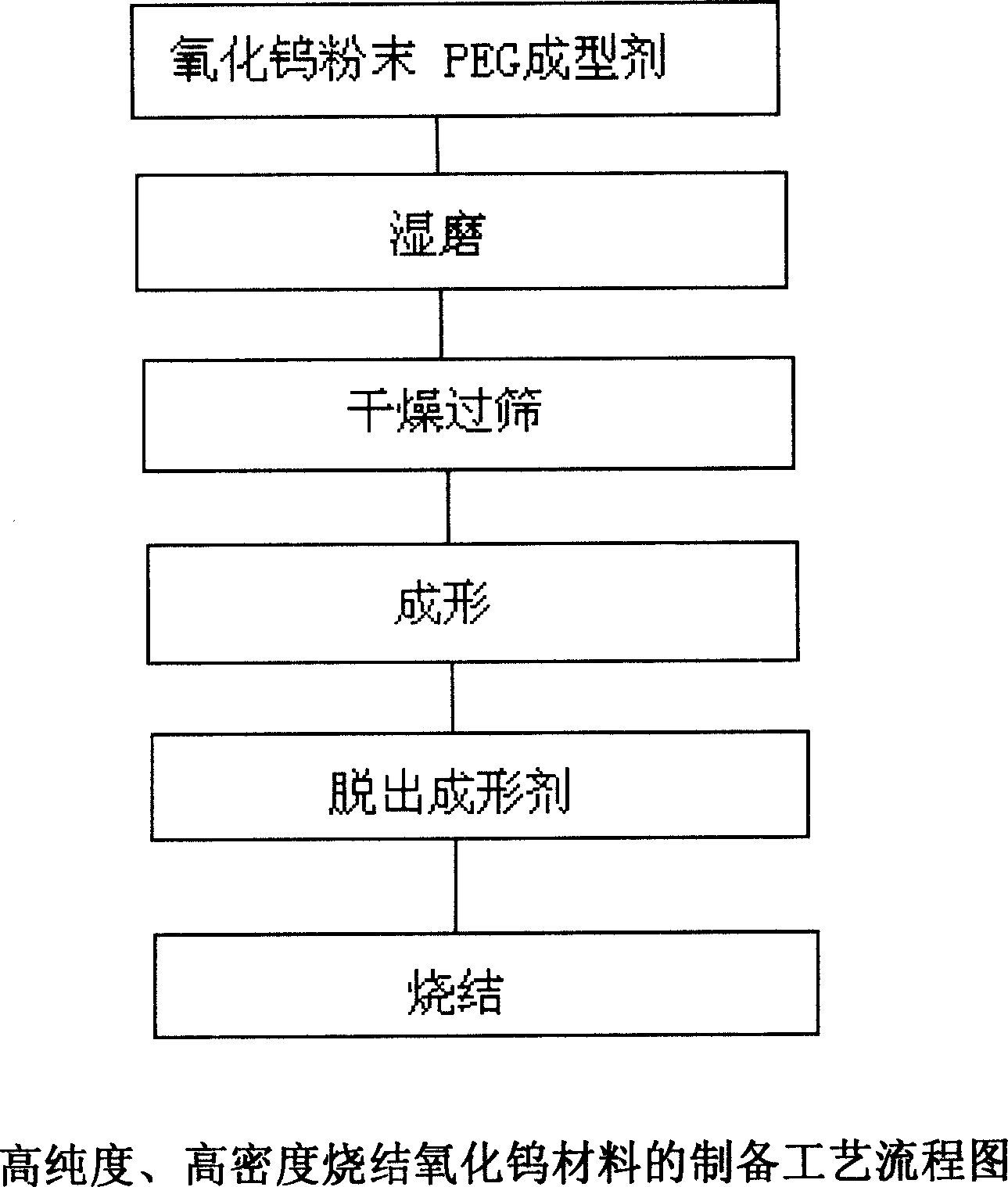

Method used

Image

Examples

example 1

[0011] Example 1: High-purity, high-density sintered tungsten trioxide

[0012] Trioxide powder (average particle size 17 microns) mixed with 1-5% (weight) polyethylene glycol (PEG) as a forming agent, added distilled water and wet milled in a ball mill for 24-96 hours, dried and sieved, at a pressure of 100-200MPa Press down to form, remove the molding agent, sinter in the silicon-aluminum rod furnace in the high-temperature furnace at 1110°C-1400°C in the air for 60-180 minutes at normal pressure, and cool with the furnace. The sintered tungsten trioxide produced in this way has a high purity Higher than 99%, density greater than 6.75g / cm 3 (relative density ≥ 94%)

example 2

[0013] Example 2: High-purity, high-density sintered tungsten trioxide

[0014] Trioxide powder (average particle size 10 microns), mixed with 1-5% (weight) polyethylene glycol (PEG) as a forming agent, added distilled water and wet milled in a ball mill for 24-96 hours, dried and sieved, at 100-200MPa Press molding under pressure, after removing the forming agent, sinter in the air at 1110°C-1400°C for 60-180 minutes at normal pressure in a high-temperature furnace, and cool with the furnace. The sintered tungsten trioxide obtained in this way has a purity higher than 99%. Target density greater than 6.82g / cm 3 (relative density≥95%)

example 3

[0015] Example 3: High-purity, high-density sintered blue tungsten oxide

[0016] Blue tungsten oxide is the intermediate oxide (β blue tungsten oxide WO 2.90 and gamma violet tungsten oxide WO 2.72 mixture. Blue tungsten oxide powder (average particle size 15 microns), mixed with 1-5% (weight) polyethylene glycol (PEG) as a forming agent, added distilled water and wet milled in a ball mill for 24-96 hours, dried and sieved, at 100 Compression molding under the pressure of -200MPa, after the molding agent is removed, sintering in the air at 1110°C-1400°C for 60-180 minutes at atmospheric pressure in a high-temperature furnace, and cooling with the furnace, the sintered blue tungsten oxide obtained in this way has a purity higher than 99%, density greater than 6.80g / cm 3 (relative density ≥ 94%)

[0017] The above three high-purity, high-density sintered tungsten oxides can be used as targets for tungsten oxide coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com