Gas containing sour milk beverage and its production process

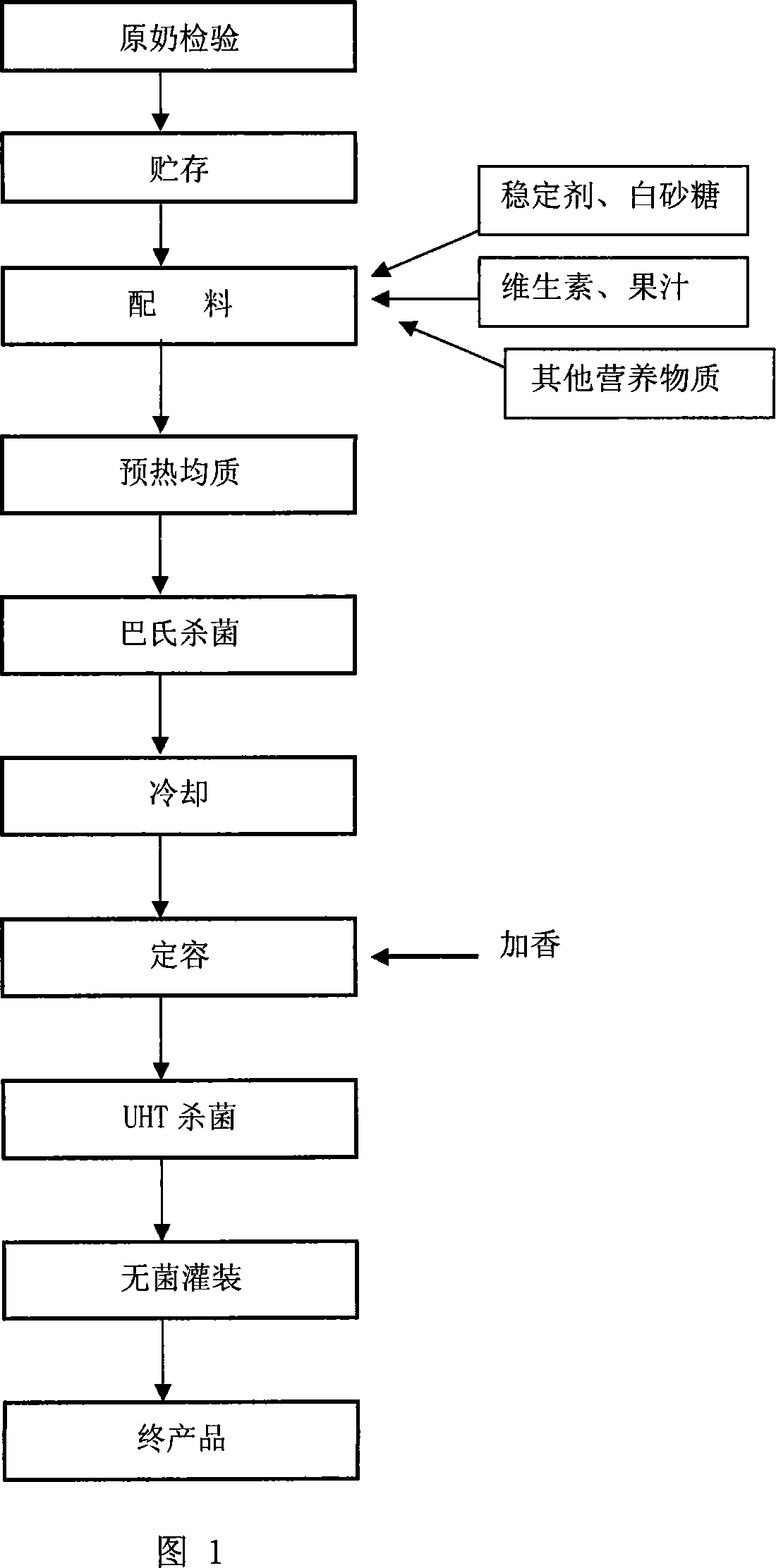

A technology for yogurt and beverages, applied in dairy products, applications, milk preparations, etc., can solve the problems of unrealistic filling, different processing methods, and large damage to nutritional components, so as to reduce the probability of microbial contamination and reduce heat treatment The number of times, the effect of realizing industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1, the preparation of the gas-containing yoghurt beverage containing orange juice

[0072] Formula (according to 1 ton):

[0073] Whey protein: 19.0 kg, orange juice: 100.0 kg, white sugar: 50.0 kg, sodium carboxymethylcellulose 1.2 kg, citric acid: 2.5 kg, lactic acid 1.5 kg, orange essence 0.35 kg, carbon dioxide 3.0 kg, purified water 475.2 kilogram. The raw materials should meet the relevant national standards.

[0074] The preparation process of this embodiment is shown in Figure 4, and the specific steps are as follows:

[0075] 1. Preparation of base liquid phase:

[0076] 1. Put an appropriate amount of pure water into the batching tank;

[0077] 2. Dissolution of the stabilizer: mix sodium carboxymethyl cellulose and white sugar evenly, take an appropriate amount of pure water and heat it to 65°C, add the mixture of the stabilizer into the hot water while stirring, and stir for 8-10 minutes , keep warm and dissolve for 10-15 minutes, cool down t...

Embodiment 2

[0091] Embodiment 2, produce the gas-containing yoghurt beverage with green tea taste

[0092] Formula: 12.5 kg of whey protein, 3.5 kg of skimmed milk powder, 20.0 kg of white sugar, 50.0 kg of fructose syrup, 0.14 kg of acesulfame potassium, 0.2 kg of aspartame, 50.0 kg of green tea powder, 3.0 kg of soybean polysaccharide, 3.0 kg of citric acid 1.5 kg of lactic acid, 1.0 kg of green tea essence, 4.0 kg of carbon dioxide, and 467.16 kg of purified water. The raw materials should meet the relevant national standards.

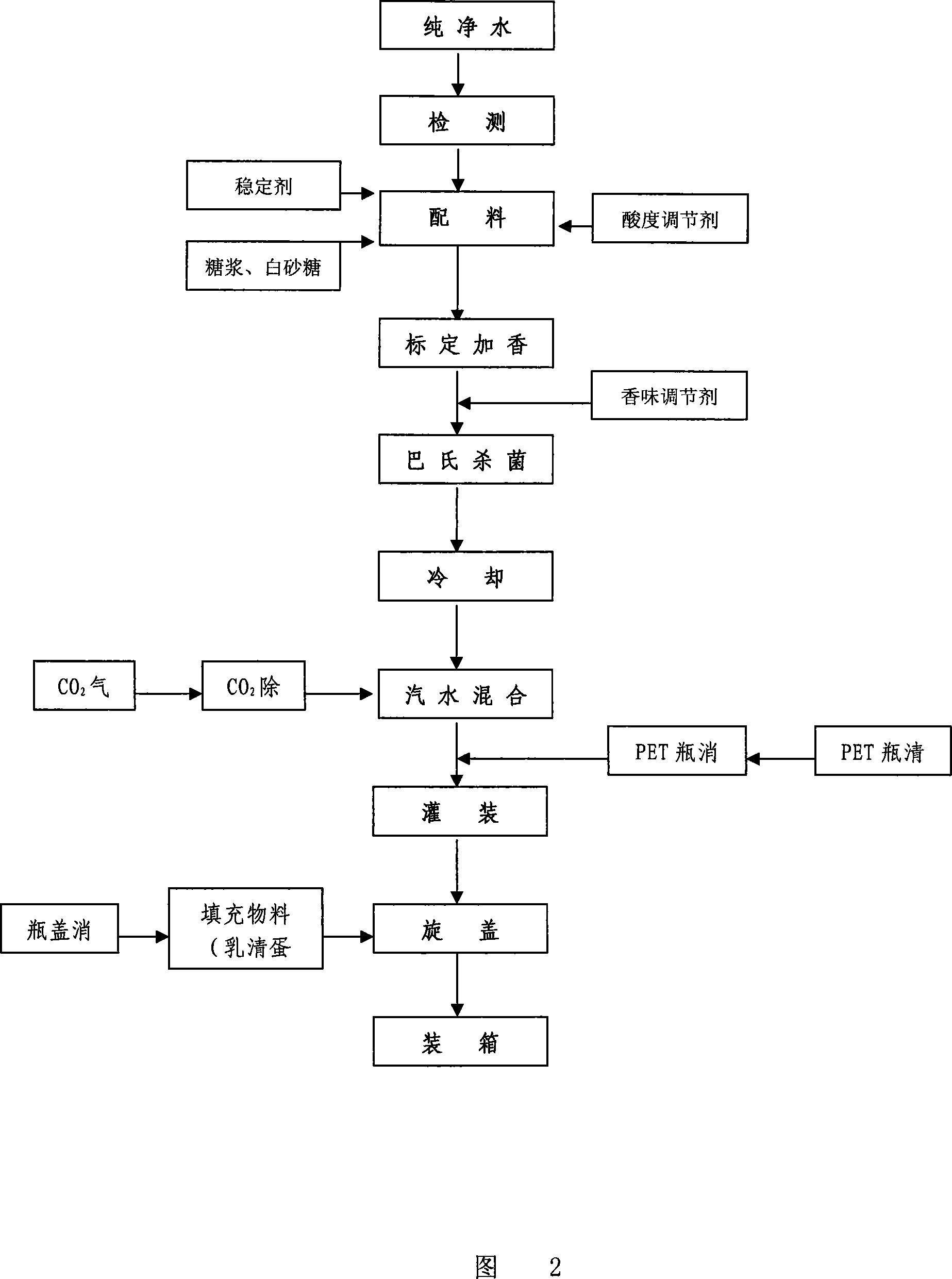

[0093] The preparation process of this embodiment is shown in Figure 2, and the specific steps are as follows:

[0094] 1. Preparation of base liquid phase:

[0095] 1. Put an appropriate amount of pure water into the batching tank;

[0096] 2. Dissolution of stabilizer: mix soybean polysaccharide with white granulated sugar, fructose syrup and sweetener evenly, take appropriate amount of pure water and heat to 50-55°C, add the mixture of stabilizer into hot...

Embodiment 3

[0109] Embodiment 3, production deployment type gas-containing yoghurt drink

[0110] Formula (according to 1 ton):

[0111] 200.0 kg of whey protein powder, 30 kg of skimmed milk powder, 60 kg of white sugar, 30 kg of fructose syrup (concentration 63%), 3.0 kg of pectin, 1.0 kg of propylene glycol alginate, 1.5 kg of citric acid, 2.0 kg of lactic acid, carbonic acid Gas 2 kg, add water to a total of 1 ton. The raw materials should meet the relevant national standards.

[0112] The preparation process of this embodiment is shown in Figure 4, and the specific steps are as follows:

[0113] 1. Preparation of base liquid phase:

[0114] 1. Put an appropriate amount of pure water into the batching tank;

[0115] 2. Dissolution of the stabilizer: Mix the pectin and white sugar evenly, take an appropriate amount of pure water and heat it to 65-70°C, add the mixture of the stabilizer into the hot water while stirring, stir for 35 minutes, keep warm and dissolve for 10 minutes. ~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com