Design and preparation for controllable hydrophobic material

A technology of co-hydrolysis and silicone, applied in small raw hide/large raw hide/leather/fur treatment, tanning treatment, leather impregnation, etc., can solve the problem of enrichment, difficult to well reflect the hydrophobic properties of silicone materials, and restrict movement. and other problems, to achieve the effect of good adhesion, convenient production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0062] Mix 100ml of toluene and 150ml of water into a 500ml flask, then take 80g of trimethylchlorosilane and 20g of methyldichlorosilane into the dropping funnel, keep the temperature below 25°C, stir, and add the mixed monomers dropwise. After the dropwise addition, pour the toluene aqueous solution into a separatory funnel, let stand, separate layers, remove the water layer, and then wash with water three times. Then add 30g of concentrated sulfuric acid, catalytic reforming at 35°C for 6 hours, then pour the mixture into a separatory funnel, let stand, separate layers, and remove the acidic water layer. Add about 0.5% mass fraction of activated carbon, stir, heat, after 30 minutes, let stand, separate layers, and remove the activated carbon. Neutralize with water and wash until the solution is neutral. Then use an oil pump to carry out vacuum distillation to collect the colorless silicon hydrogen reagent I.

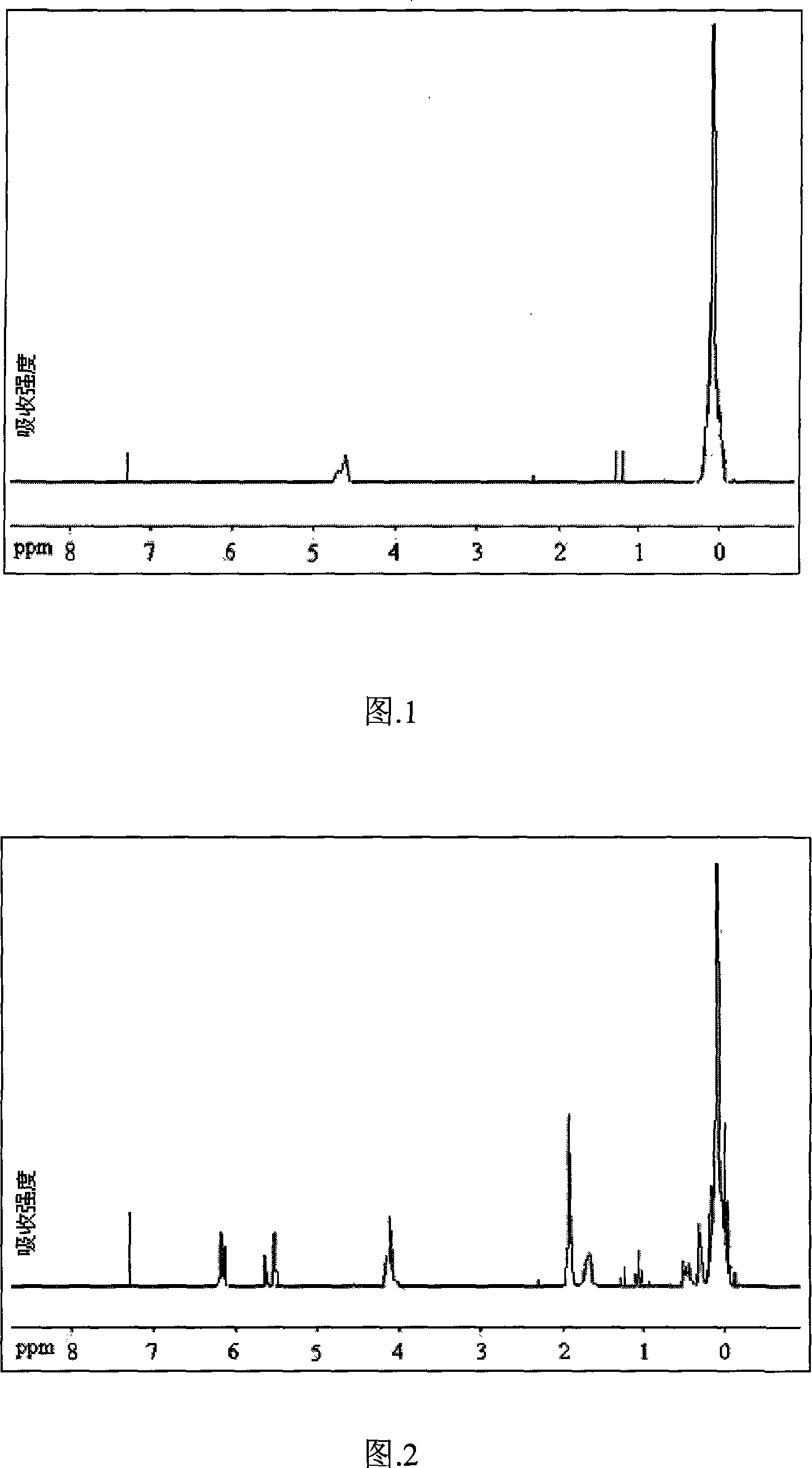

[0063] It can be seen from Fig. 1 that there are mainly two gr...

example 2

[0065] Mix 100ml of toluene and 150ml of water into a 500ml flask, then take 50g of trimethylchlorosilane, 30g of diphenyldichlorosilane and 20g of methyldichlorosilane into the dropping funnel, and control the temperature below 25°C. Stir and add the mixed monomers dropwise. After the dropwise addition, transfer the mixed solution into a separatory funnel, let stand, separate layers, remove the water layer, and then wash with water three times. Slowly add 30 g of concentrated sulfuric acid, and carry out catalytic reforming at 35° C. for 6 hours, then pour the mixture into a separatory funnel, let stand, separate layers, and remove the acid layer. Add about 0.5% mass fraction of activated carbon, stir and heat, and after about 30 minutes, let stand and separate layers to deactivate the carbon. Neutralize with water and wash until the toluene solution is neutral. Finally, carry out vacuum distillation with an oil pump to collect colorless silicon hydrogen reagent.

example 3

[0067] Take by weighing the product of 12.5g example 1, put into and be equipped with mechanical stirrer, N 2 Add 5 drops of isopropanol solution containing 1% chloroplatinic acid to the four-neck flask with gas inlet, dropping funnel, and condenser tube, 2 Under air protection, stir to make it evenly mixed. Then take 6.3g of allyl methacrylate and measure it into the dropping funnel. Control the temperature in a water bath at 70°C, stir, and pass in N 2 Gas, then slowly add allyl methacrylate dropwise. After the dropwise addition, the temperature was raised to 90°C, the reaction was continued for 6h, and cooled. A colorless and transparent oily liquid was obtained.

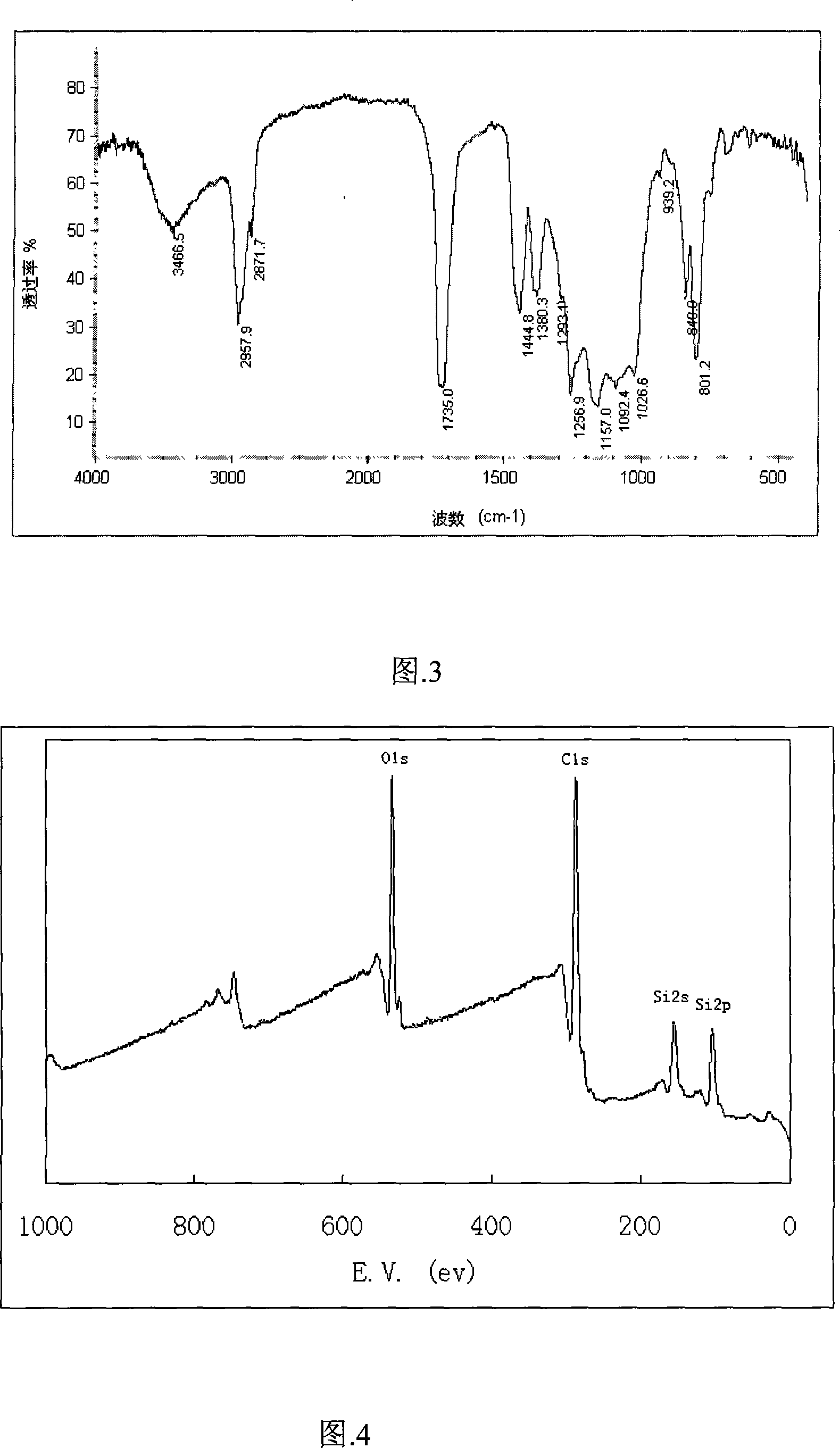

[0068] It can be seen from Fig. 2 that the hydrogen peak Si-H at 4.6575-4.7127ppm disappears, and CH appears at 6.093-6.1294, 5.5304-5.6101, 4.0689-4.1145, 1.6660 and 1.9196-1.9474ppm respectively 2 =C(CH 3 )-, O-CH 2 -, O-CH 2 -CH 2 and CH 2 =C(CH 3 )-peaks. without CH 2 = The peak of CH, which show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com