Electrostatic latent image developing toner and image forming method

An electrostatic latent image and toner technology, which is applied in the directions of developers, electrographics, optics, etc., can solve the problems of density deviation, insufficient charging amount, and the speed of frictional charging cannot catch up with the speed of toner consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

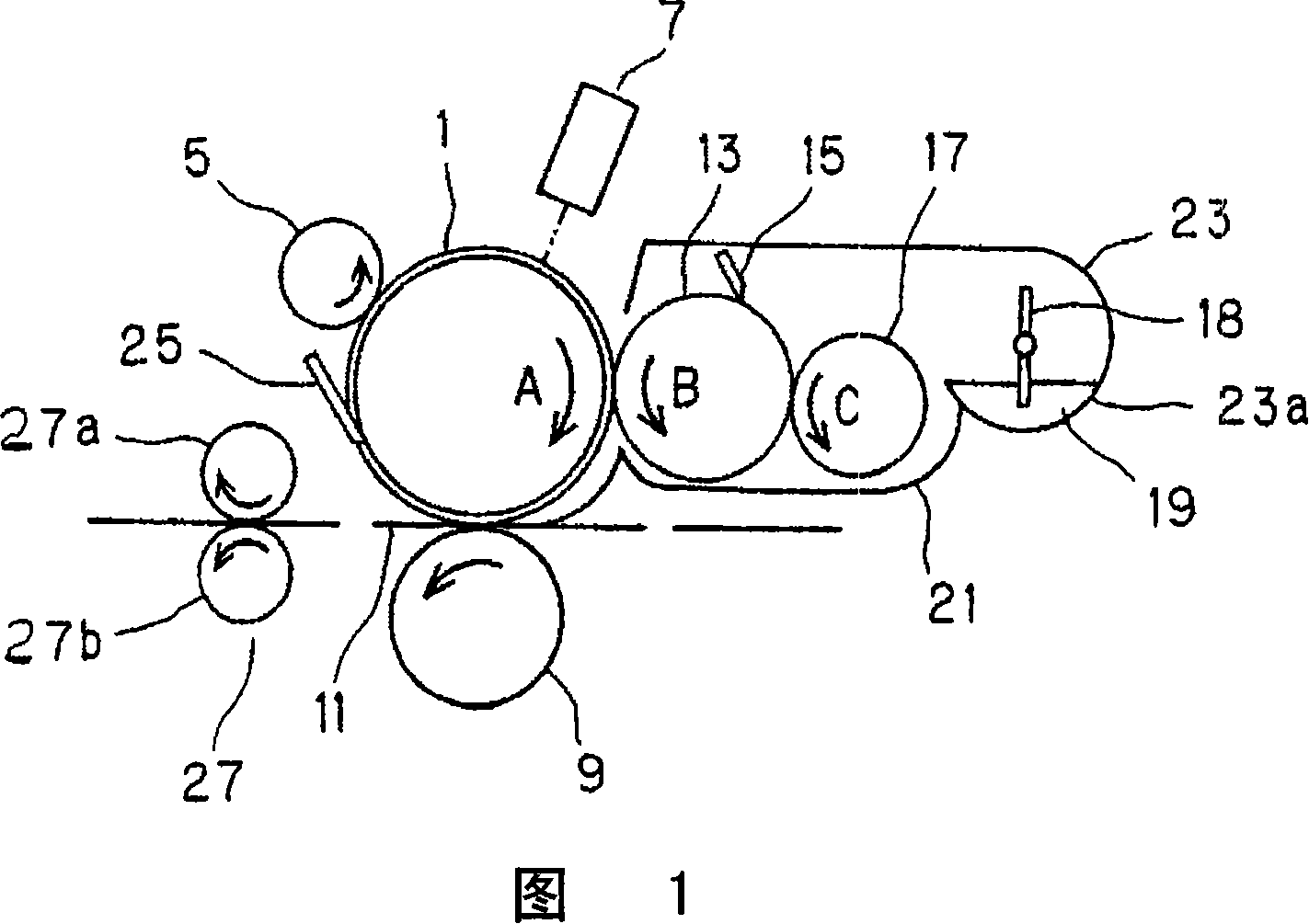

Image

Examples

preparation example Construction

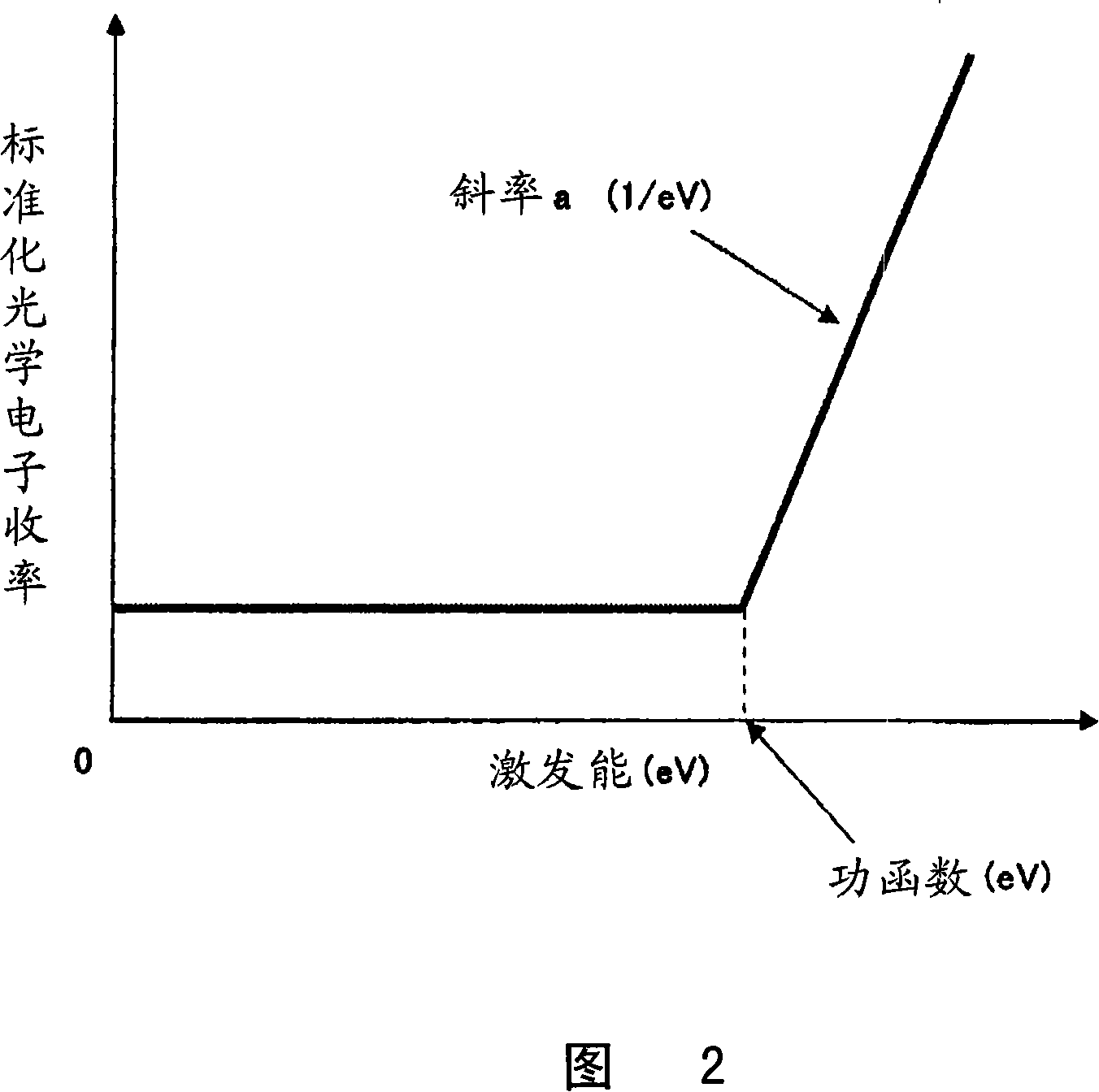

[0133] In the method for preparing the toner described above, in order to obtain the work function X (eV) of the toner in the work function measurement and the slope A of the normalized photoelectron yield relative to the excitation energy (normalized photoelectron yield / excitation energy) (1 For a toner for developing an electrostatic latent image in the range of 5.350, / eV) is preferably the following method.

[0134] (1) As described above, a suitable amount of phthalocyanine metal salt is dispersed in the polymerizable monomer for the sheath layer, and then the dispersion liquid is added to the aqueous dispersion liquid in which the core layer particles are dispersed, and polymerization is carried out. A sheath layer containing metal phthalocyanine salts is formed on the surface.

[0135] (2) As mentioned above, after mixing the coloring agent and the antistatic resin, the antistatic resin composition prepared in advance contains epoxy compounds with radical polymerizabili...

Embodiment

[0162] The present invention is further described in detail through the following examples, but the present invention is not limited to the following examples. Parts and % are based on weight unless otherwise specified.

[0163]

[0164] The experimental method carried out in this example is as follows.

[0165] (1) Particle size

[0166] Volume average particle size (Dv), particle size distribution that is the ratio of volume average particle size (Dv) to number average particle size (Dp) (Dv / Dp), and the number % of colored particles with a particle size of 4 μm or less Measured with a particle size analyzer (manufactured by Beckman Coulter, trade name "Mulchisizer"). The measurement of this maltoseiza was carried out under the conditions of pore diameter: 100 μm, medium: Isoton II, and number of measured particles: 100,000.

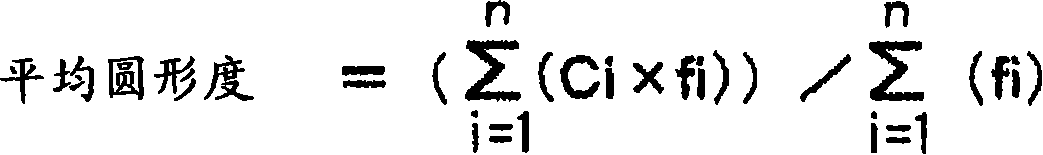

[0167] (2) Average circularity of toner

[0168] 10 ml of ion-exchanged water was placed in the container in advance, 0.02 g of surfactant (alky...

preparation example 1

[0192]100 parts of antistatic resin polymerized by 82 parts of styrene, 11 parts of butyl acrylate, and 7 parts of 2-acrylamide-2-methylpropanesulfonic acid (weight-average molecular weight: 20,000, glass transition temperature: 65°C ) was dispersed in a mixed solvent containing 24 parts of methyl ethyl ketone and 6 parts of methanol, and kneaded with rollers while cooling. While the antistatic resin was wound on a roll, 100 parts of cyan pigment C.I. Pigment Blue 15:3 (manufactured by Claria Anto) was slowly added and kneaded for 1 hour to prepare an antistatic resin composition. At this time, the initial distance between the rollers was 1mm, and then the distance was gradually increased, and the organic solvent (toluene / methanol=4 / 1 mixed solvent) was added in several times while observing the kneading state of the antistatic resin composition (mixed amount: 3 parts) ) and 3 parts glycidyl methacrylate (GMA).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com