Method for preparing Nano silver solution

A nano-silver and solution technology, applied in the field of preparation of nano-silver solution, can solve the problems of difficult industrial control, complex technical process, unstable production, etc., and achieve the effects of easy particle size, stable synthesis process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

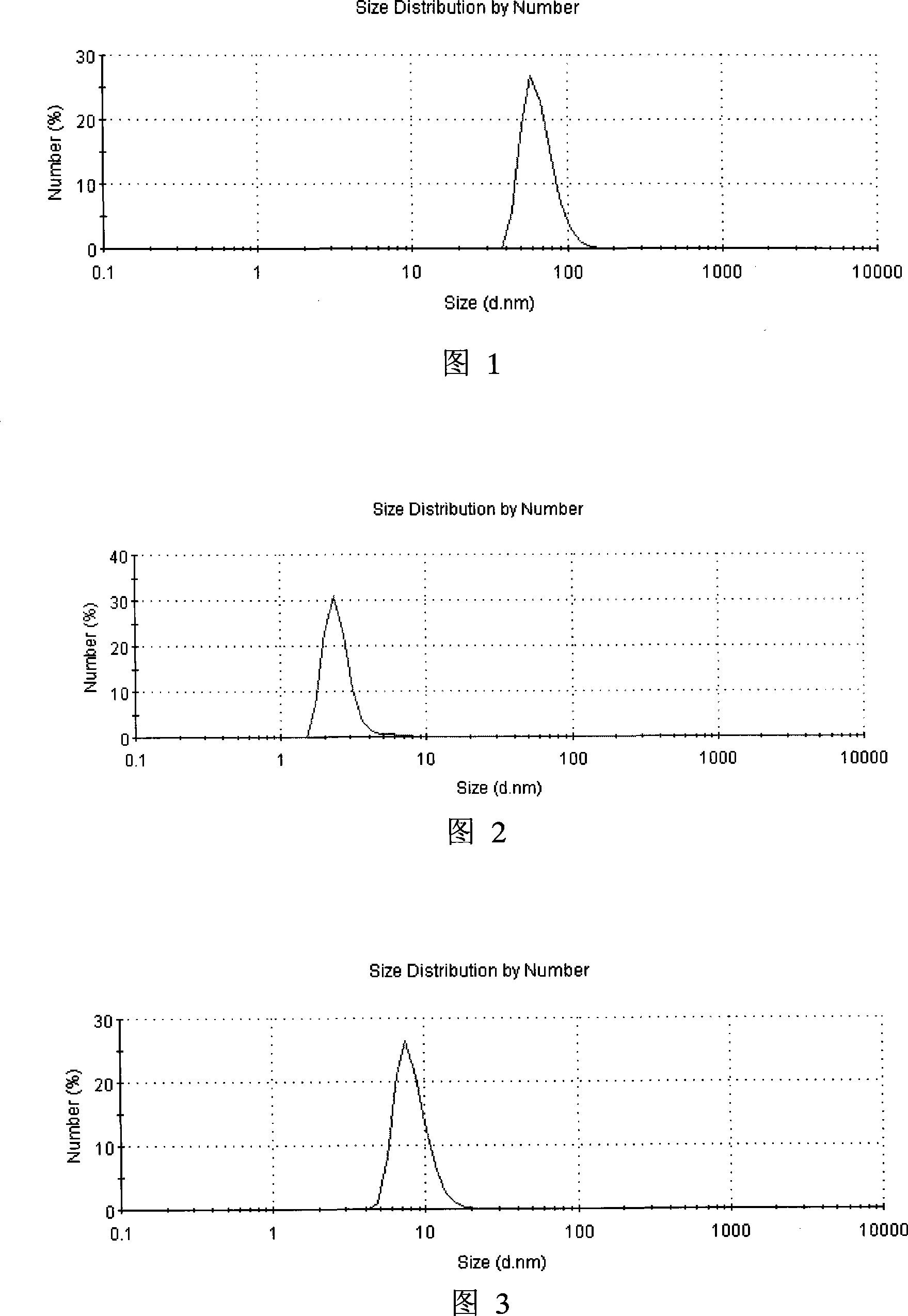

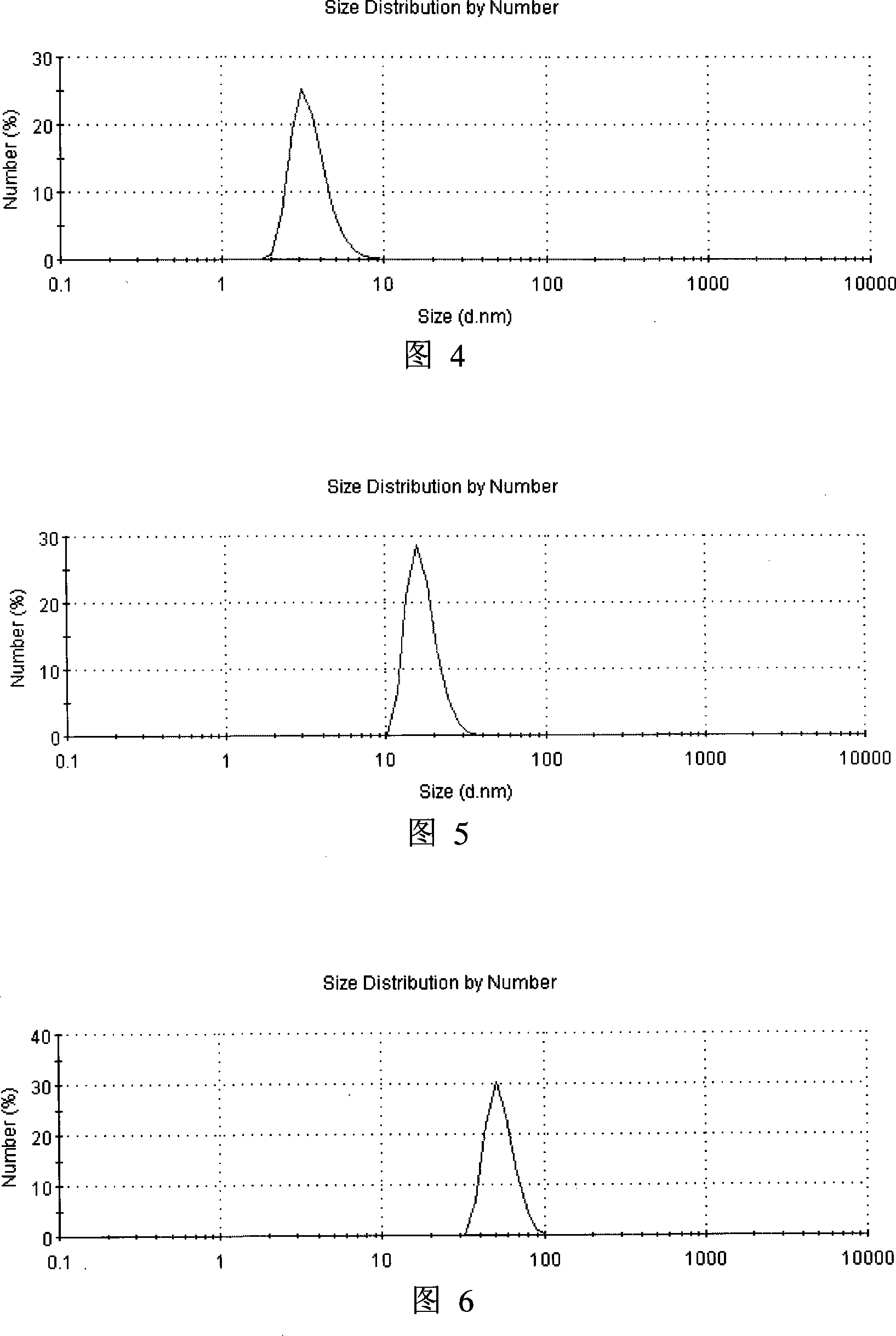

[0038] As shown in Figure 1, a kind of preparation method of nano-silver solution, the main raw material of described nano-silver solution comprises AgNO 3 , hydrazine hydrate, gellan gum, propylene glycol, triethanolamine, and its weight ratio is AgNO 3 : hydrazine hydrate: gellan gum: propylene glycol: triethanolamine=0.8: 0.8: 0.1: 1.8: 2.8, and prepared according to the following steps,

[0039] a) Prepare AgNO respectively according to the conventional preparation process 3 and the aqueous solution of hydrazine hydrate, after filtering for subsequent use;

[0040] b), mix gellan gum with powdered NaCl or sugar according to the weight ratio of gellan gum: NaCl / sugar=1:9, then put the homogeneously mixed mixture into the ultrasonic field In the high-shear dispersing emulsifier reaction kettle, then add water, heat to 50°C, and the rotation speed is 500rpm / min, under the strong mechanical and hydraulic shearing and centrifugal extrusion produced by the ultrasonic wave and ...

Embodiment 2

[0045] As shown in Figure 2, a kind of preparation method of nano-silver solution, the main raw material of described nano-silver solution comprises AgNO 3 , ascorbic acid, gellan gum, polyethylene glycol, TX-10, its weight ratio is AgNO 3 : ascorbic acid: gellan gum: polyethylene glycol: TX-10=1.2: 1.2: 0.5: 2.2: 3.2, and prepared according to the following steps,

[0046] a) Prepare AgNO respectively according to the conventional preparation process 3 And the aqueous solution of ascorbic acid, standby after filtering;

[0047] b), mix gellan gum with powdered NaCl or sugar according to the weight ratio of gellan gum:NaCl / sugar=1:11, then put the uniformly mixed mixture into an ultrasonic field In the high-shear dispersing emulsifier reaction kettle, then add water, heat to 70°C, and the rotation speed is 700rpm / min, under the strong mechanical and hydraulic shearing and centrifugal extrusion produced by the ultrasonic wave and high-shear dispersing emulsifier , liquid lay...

Embodiment 3

[0052] As shown in Figure 3, a kind of preparation method of nano-silver solution, the main raw material of described nano-silver solution comprises AgNO 3 , sodium citrate, gellan gum, glycerin, Tween, its weight ratio is AgNO 3 : sodium citrate: gellan gum: glycerol: Tween=1: 1: 0.3: 2: 3, and prepared according to the following steps,

[0053] a) Prepare AgNO respectively according to the conventional preparation process 3 and an aqueous solution of sodium citrate, filtered for subsequent use;

[0054] b) Mix gellan gum with powdered NaCl or sugar according to the weight ratio of gellan gum: NaCl / sugar=1:10, then put the homogeneous mixture into the ultrasonic field In the high-shear dispersing emulsifier reaction kettle, then add water, heat to 60°C, and the rotation speed is 600rpm / min, under the strong mechanical and hydraulic shearing and centrifugal extrusion produced by ultrasonic waves and high-shear dispersing emulsifier , liquid layer friction, impact tearing an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com