Method for preparing polypyrole-polycarbonate composite membrane fixed and carried cibacron blue

A technology of polycarbonate and Cymbal blue, which is applied in the field of affinity membrane preparation, can solve the problems of lack of active functional groups, etc., and achieve the effects of excellent hydrophilicity, easy preparation and storage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Pretreatment of basement membrane:

[0025] Take a polycarbonate membrane with a pore size of 0.8 μm, a thickness of 20 μm, and a diameter of 25 mm, soak it in a 30-mL aqueous solution of Cymbal blue with a concentration of 0.2 mmol / L for 30 min, and then place the membrane in a filter with 30 mL of 0.2 The mmol / L Cymbal blue solution was suction filtered 5 times.

[0026] 2) Doping of ligands and oxidation deposition of polypyrrole:

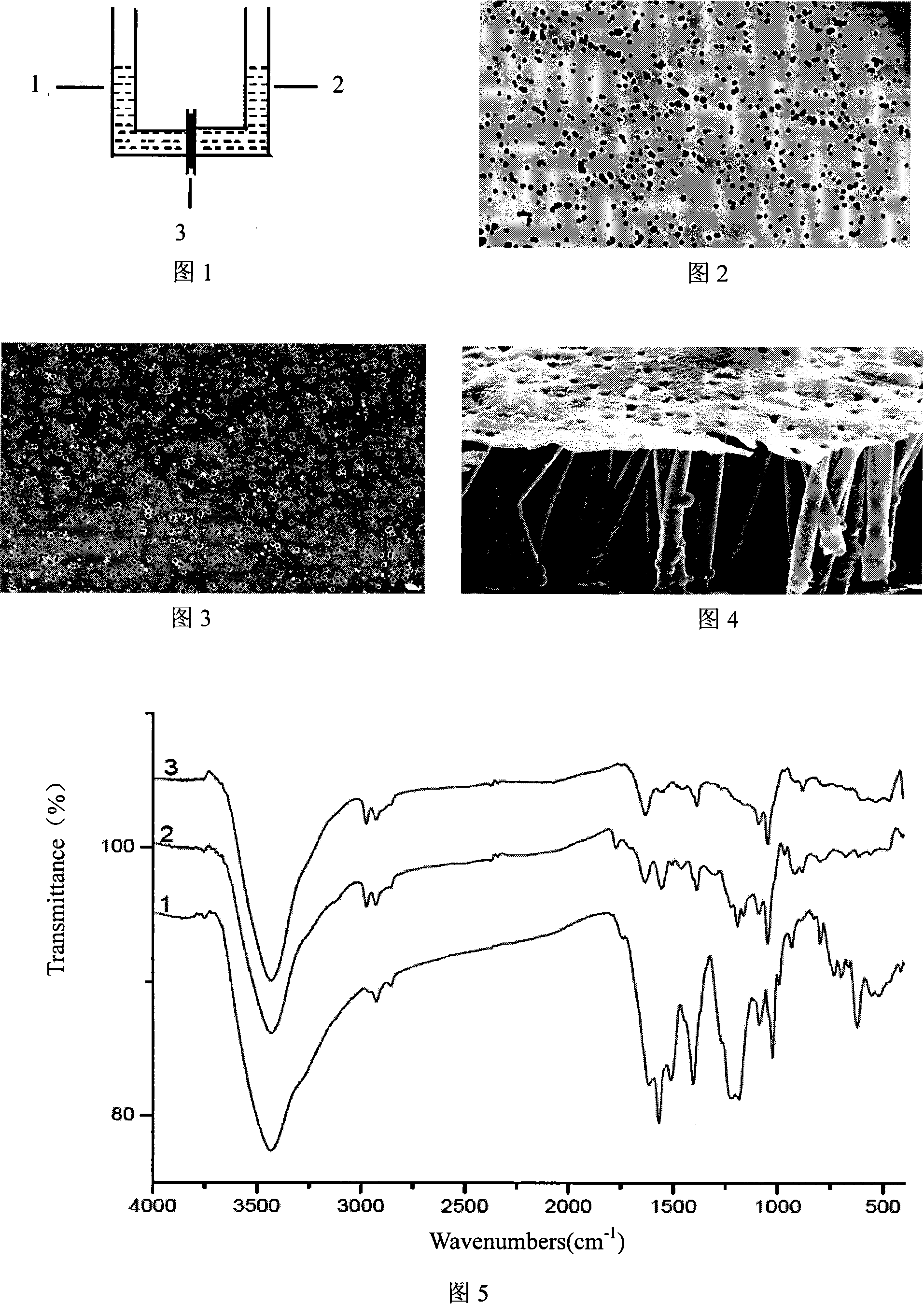

[0027] Get the base film 3 processed by step 1 and fix it in the middle of the diffusion cell device with double cells 1 and 2 (see Figure 1), add 30mmol / L ammonium persulfate aqueous solution 30mL in the pool 1 of the diffusion cell; Add 30mL of a mixed solution containing cymbal blue and pyrrole monomer, the concentration of cymbal blue in pool 2 is 0.2mmol / L, and the concentration of pyrrole monomer is 15mmol / L. Reacted at 4°C for 2.5h.

[0028] 3) Membrane cleaning and preservation:

[0029] After the reaction time is set, the ...

Embodiment 2

[0033] 1) Pretreatment of basement membrane:

[0034] Take a polycarbonate membrane with a pore size of 0.2 μm, a thickness of 20 μm, and a diameter of 25 mm, and fix it in the middle of the diffusion cell device, add 30 mL of 0.4 mmol / L Cymbal blue aqueous solution to Pool 1, and let it stand for 2 hours to diffuse the Cymbal blue through the basement membrane.

[0035] 2) Doping of ligands and oxidation deposition of polypyrrole:

[0036] Pour out the aqueous solution of Cymbal blue in step 1, then add 30mL of 300mmol / L ferric chloride aqueous solution to Pool 1; The concentration of balan is 0.4mmol / L, and the concentration of pyrrole monomer is 100mmol / L. React at 0°C for 30 min.

[0037] 3) Membrane cleaning and storage:

[0038] According to the method of Example 1, the polypyrrole-polycarbonate composite membrane immobilized with Cymbal blue was obtained by cleaning and storing.

Embodiment 3

[0040] 1) Pretreatment of basement membrane:

[0041] Take a polycarbonate membrane with a pore size of 3 μm, a thickness of 20 μm, and a diameter of 25 mm, place it in a device that can be sealed and vacuumed, add 30 mL of Cymbal blue aqueous solution with a concentration of 0.6 mmol / L, and use a vacuum pump to reduce the vacuum degree of the device. Keep at 30kPa for 20min.

[0042] 2) Doping of ligands and oxidation deposition of polypyrrole:

[0043]Take out the basement membrane treated in step 1 and fix it in the middle of the diffusion cell device, add 30 mL of aqueous hydrogen peroxide solution with pH 2 into pool 1 of the diffusion cell; The concentration of Cymbal blue in pool 2 is 0.6mmol / L, and the concentration of pyrrole monomer is 15mmol / L. Reaction at 0°C for 4h.

[0044] 3) Membrane cleaning and storage:

[0045] According to the method of Example 1, the polypyrrole-carbonate composite membrane with immobilized Cymbal blue was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com