Field effect transistor, organic thin-film transistor and manufacturing method of organic transistor

A technology of field effect transistors and organic thin films, which is applied in the field of manufacturing field effect transistors, organic thin film transistors and organic transistors, can solve problems such as inapplicability, and achieve the effect of light weight manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] In this example, the discussion of Non-Patent Document 8 is expanded, and a method of deriving the Schottky barrier Φ at the electrode-organic semiconductor interface is derived from the physical constants of the constituent elements of the electrode and semiconductor. Through theoretical calculations using first-principles calculations and electronic state measurements using scanning tunneling microscopy, for combinations as electrodes-organic semiconductors, hydrogen-terminated silicon surfaces-polythiophene polymers, gold-pentacene crystals, silver-pentacene After studying the electronic states of crystals, gold-various thiol monomolecular films, silver-various thiol monomolecular films, etc., the Schottky barrier can be generally estimated using (Eq. Φ. That is, when the carriers are electrons, the Schottky barrier Φ is given by (equation 7).

[0068] Φ=γ B ( M -χ S )+(1-γ B )E g / 2 (number 7)

[0069] Here, (number 8) to (number 10) are as follows.

[0070...

Embodiment 2

[0078] In this embodiment, an example of the CTFT transistor of the present invention is disclosed.

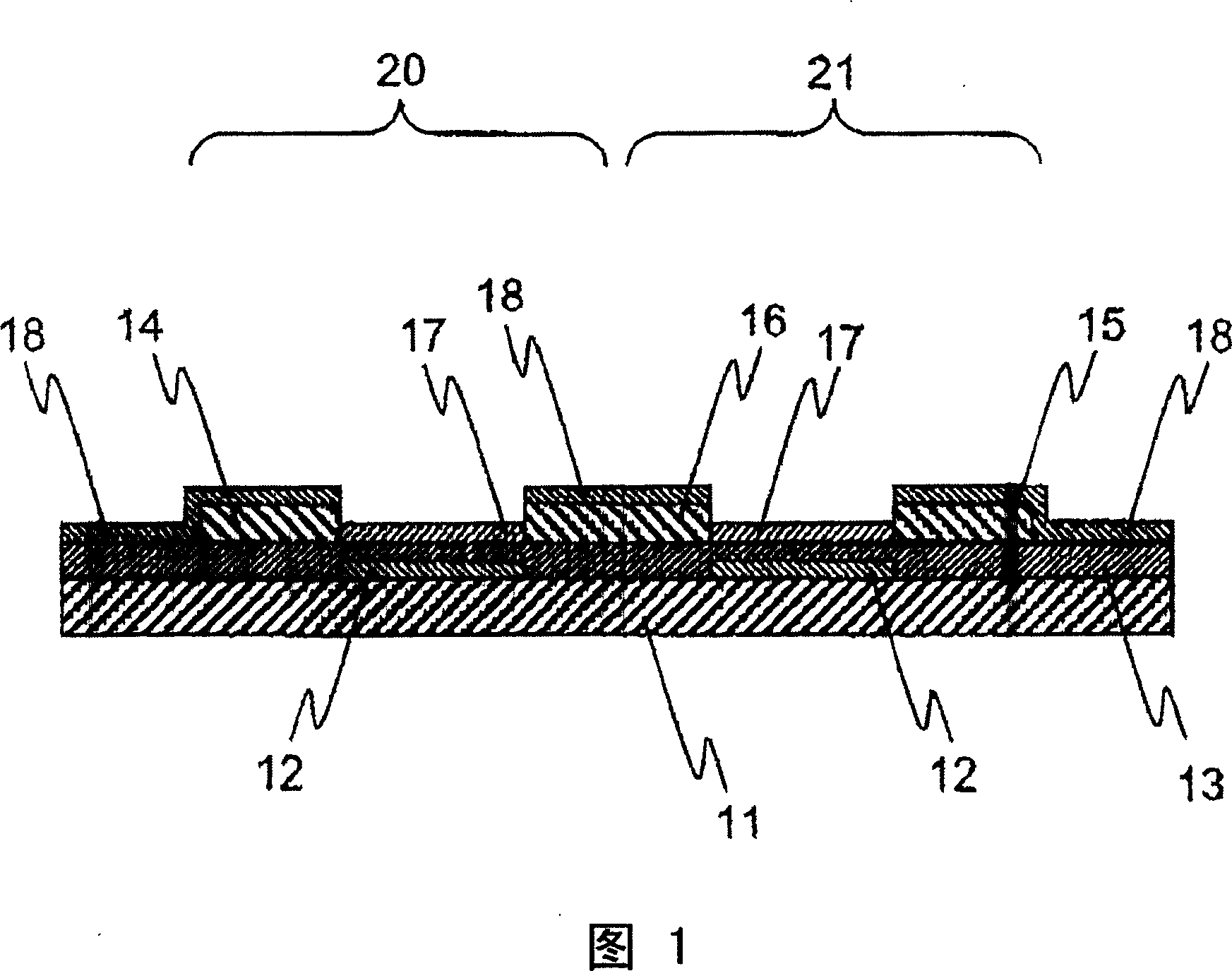

[0079] FIG. 1 is a schematic cross-sectional view showing the structure of a CTFT transistor of the present invention. In FIG. 1 , the organic semiconductor thin film 17 is a polycrystalline pentacene thin film composed of pentacene crystal grains in this embodiment. The source 14 and source 15, the organic semiconductor thin film 17, the common drain 16, and the two gates 12 constitute a CTFT transistor. The CTFT transistor is a structure in which an n-type channel FET 20 and a p-type channel FET 21 are connected in series. In this embodiment, the source 15 is a ground electrode, and the source 14 is an electrode for applying an operating voltage. On the two gates 12 A common voltage signal is input, and the drain 16 is an output electrode. The liquid repellent region 18 is a region with high liquid repellency. In the stage before the formation of the organic semiconductor ...

Embodiment 3

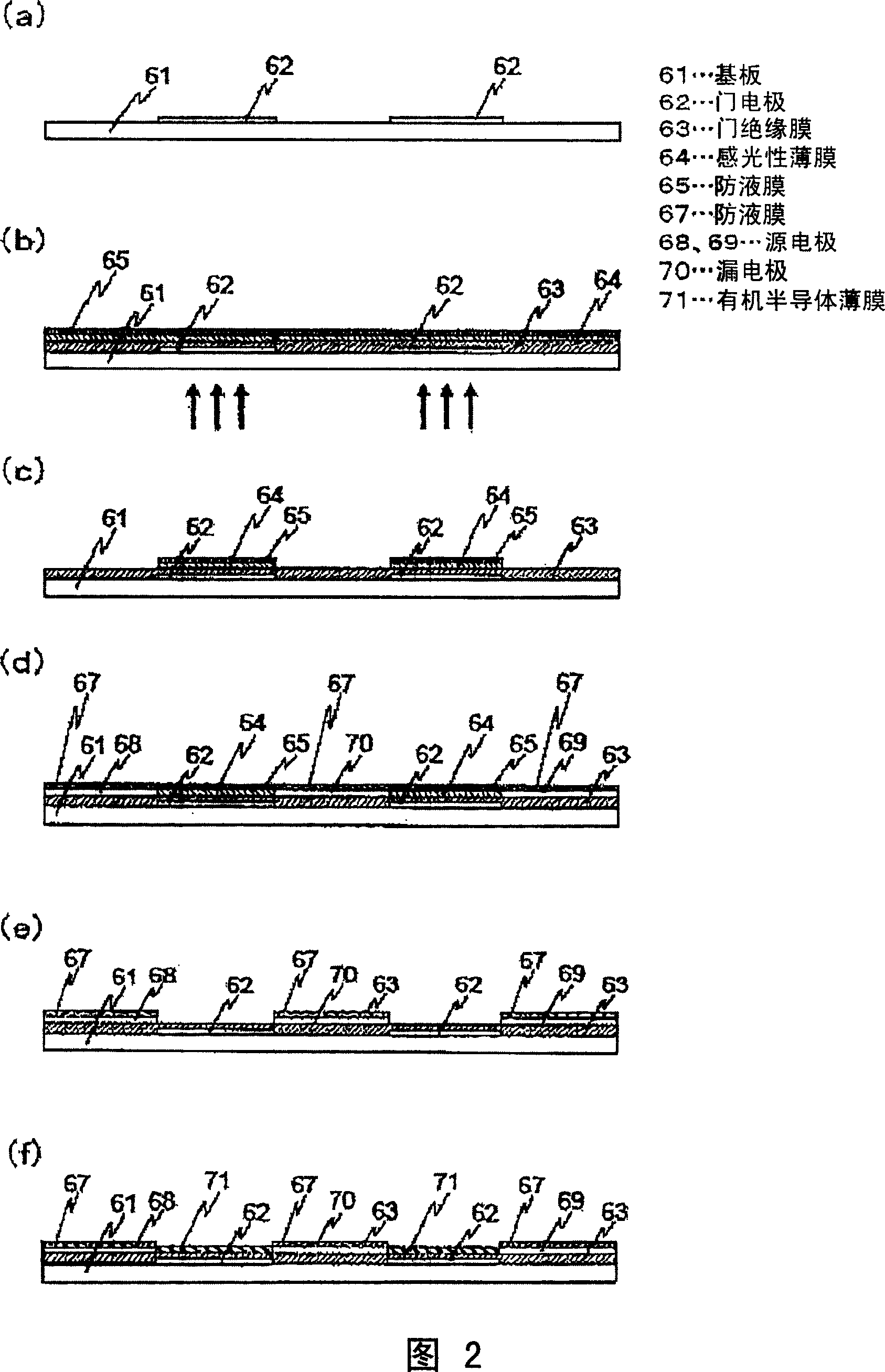

[0083] An example of a method of manufacturing a CTFT transistor formed according to the present invention is disclosed in this embodiment. FIG. 2 is a cross-sectional view showing an example of a method of manufacturing a CTFT transistor formed according to an embodiment of the present invention. In this example, a method of forming the organic thin film CTFT transistor of the present invention by printing, coating, etc., instead of lithography using a plastic material is described. 2(a)-(f) are diagrams specifically explaining the manufacturing method.

[0084] As shown in FIG. 2( a ), a gate electrode 62 is printed on a plastic substrate 61 using conductive ink. This is fired to form the gate electrode 62, but since the substrate is made of plastic, attention must be paid to its softening temperature. In this embodiment, the substrate 61 uses a highly heat-resistant and highly transparent polyimide sheet with a thickness of 100 μm, and the firing temperature can be raised...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com