Woven structure of belt form and method for production thereof

A structure and fabric technology, applied in the direction of fabric, seat belt/sling structure, weaving, etc., can solve the problems of easy occurrence of yarn cutting, poor bending, poor productivity, etc., and achieve excellent anti-distortion effect and excellent wearing. good feeling and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

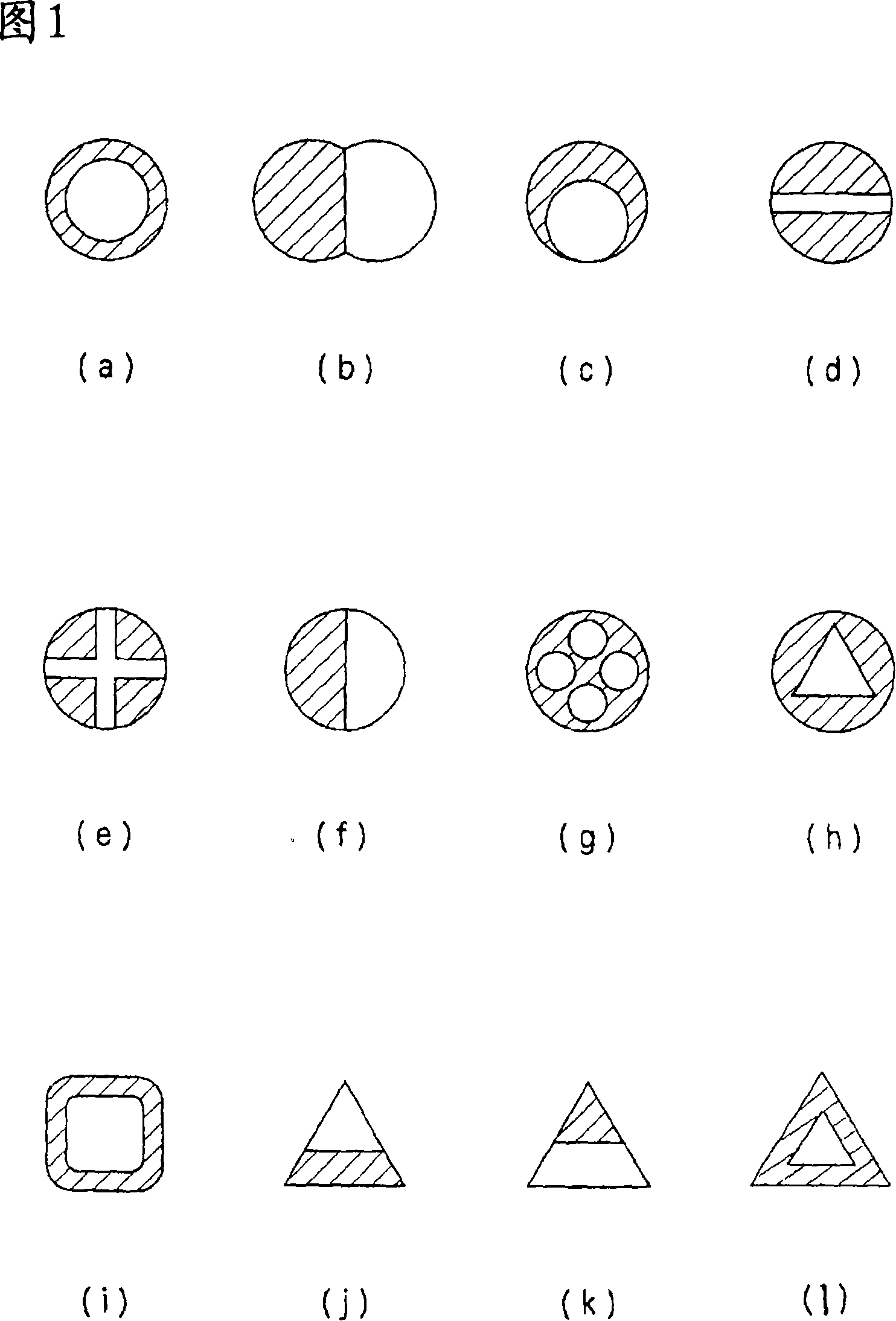

Image

Examples

Embodiment 1

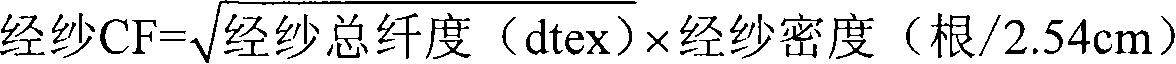

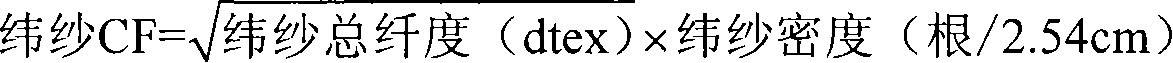

[0089] As the warp yarn, a black polyester multifilament dyed with a stock solution of 1670dtex / 144f, a breaking strength of 8.4cN / dtex and an elongation of 12% is arranged to a warp density of 390 threads / 2.54cm, and as a weft yarn, a sheath component of 280dtex / 16f It is a core sheath of polyethylene terephthalate copolymerized with 25 mol% isophthalic acid (softening point 185°C) and the core component is polyethylene terephthalate (melting point 240°C) with an intrinsic viscosity of 0.68 Type hot-melt polyester yarn (manufactured by Kanebo Kanebo Co., Ltd., Bellcouple [registered trademark], core / sheath ratio = 3 / 2), and 720dtex / 72f (softening point 240°C), breaking strength 6.5cN / dtex, elongation 20% polyester fiber is combined with silk, and the tape is woven with a knitting machine according to a width of 5cm and a weft density of 20 / 2.54cm. Next, the tape is heat-treated at a temperature of 200°C to melt the sheath component, and the surrounding polyester fiber is melt-fix...

Embodiment 2

[0091] As the weft yarn, instead of the core-sheath type hot-melt polyester yarn of Example 1, the total amount of 280dtex / 48f was used copolymerized with 5 mol% isophthalic acid and 5 mol% 2,2-bis[4-(2 -Carboxyethoxy)phenyl]propane copolymer component polyester multifilament (softening point 200°C, limiting viscosity 0.69, maximum heat shrinkage stress 0.23cN / dtex, BWS23%, 130°C dry heat shrinkage rate 21%, 180 ℃ dry heat shrinkage rate 30%), except that it is the same as the above-mentioned Example 1, to obtain the target belt-shaped fabric structure.

Embodiment 3

[0093]In place of the core-sheath hot-melt polyester yarn of Example 1, a 167dtex / 48f sheath component is polyethylene terephthalate (softening point 185°C) copolymerized with 25 mol% isophthalic acid and the core component is used It is a core-sheath type hot-melt polyester yarn of polyethylene terephthalate (softening point 240°C) with an intrinsic viscosity of 0.68 (manufactured by Kanebo Co., Ltd., Bellcouple [registered trademark], core / sheath ratio = 2 / 1 ), except that it was the same as in Example 1 above, and the target belt-shaped fabric structure was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com