High-strength highly-conductive low-calcium boron chromic zirconium copper alloy and method for manufacturing same

A zirconium-copper alloy and chromium-zirconium-copper technology, which is applied in the field of chromium-zirconium-copper alloy and its manufacture, can solve the problems of unbalanced performance and high performance value, and achieve good wear resistance, good machinability and high softening point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with specific embodiment:

[0021] The production process of the rod (plate) wire rod of chromium-zirconium copper alloy in the embodiment of the present invention is as follows:

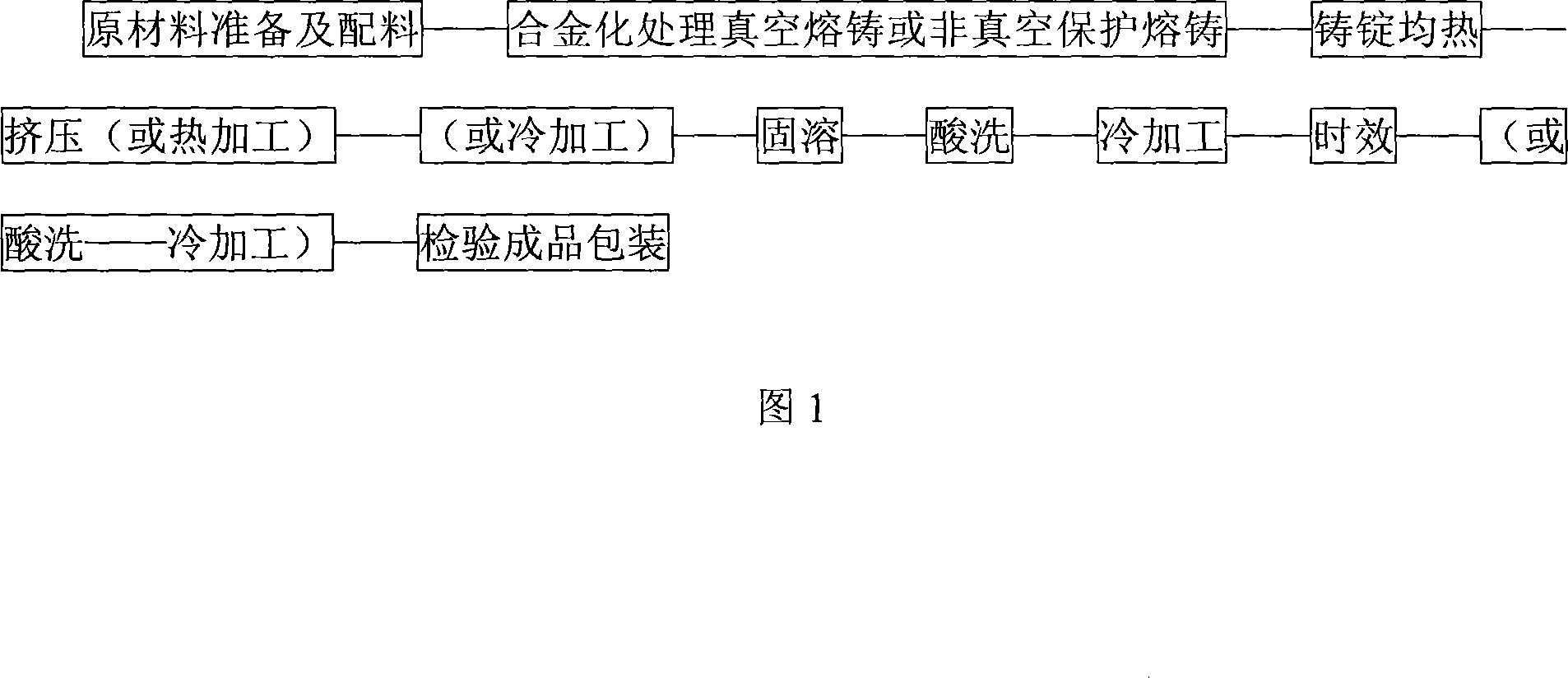

[0022] Raw material preparation and batching - alloying treatment vacuum casting or non-vacuum protection melting casting - ingot soaking - extrusion (or hot working) - (or cold working) - solid solution - pickling - cold working - Aging—(or pickling—cold processing)—inspection of the finished package (see Figure 1).

[0023] Specifically, it can be expressed as follows: prepare raw materials and ingredients according to the chemical composition of the alloy, use alloying treatment and vacuum melting casting or non-vacuum protection melting casting method to melt low calcium boron chromium zirconium copper alloy, so that chromium, zirconium, calcium, boron, etc. and copper form The master alloy is melted rapidly and ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com