Resin composition for electronic and electric components for high-frequency applications and its molded product

A resin composition, electronic and electrical technology, used in the fields of electronic and electrical components, antenna substrates, and filters, can solve the problems of impairing mechanical properties, impact strength, injection moldability, sheet extrusion moldability, etc., and achieve stable dielectric properties. , The effect of improving shrinkage resistance and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~5

[0104] Install a die width of 750 mm and a die lip width of 0.5 mm on a single-screw extruder with a sub-extruder capable of multi-layer molding of 65 mmφ and L / D=28, and set the cylinder temperature to At 300°C, extrude the graphite-added resin composition shown in Table 1 as a single layer, and extrude the titanium oxide-added resin composition shown in Table 2 as a single-layer and multi-layer extrude to obtain a 500 μm sheet molding.

[0105] Table 3 lists the sheet extrusion formability of each resin composition and the dielectric properties of the sheet molded body at 25° C. and 1 GHz.

Embodiment 4

[0106] The resin composition containing 10% by weight of graphite in Example 4 shrank and was difficult to mold, but the resin composition containing 5% by weight or less of graphite had good sheet extrusion formability. In addition, the resin composition added with 30% by weight of titanium oxide in Comparative Example 4 had severe shrinkage and could not be molded, but the extrusion formability of the multilayer sheet in Example 5 was good, indicating that the extrusion molding of the sheet can be performed by multilayering. performance has been significantly improved.

[0107] The results show that the dielectric loss tangent of the sheet added with graphite with an average particle size of 20 μm in Example 1 and the sheets added with graphite with an average particle size of 60 μm in Examples 2 to 4 is 0.0025 or less. The dielectric loss tangent of the sheet of graphite with an average particle diameter of 5 μm is 0.0045, and the dielectric loss tangent of the sheet added ...

Embodiment 6

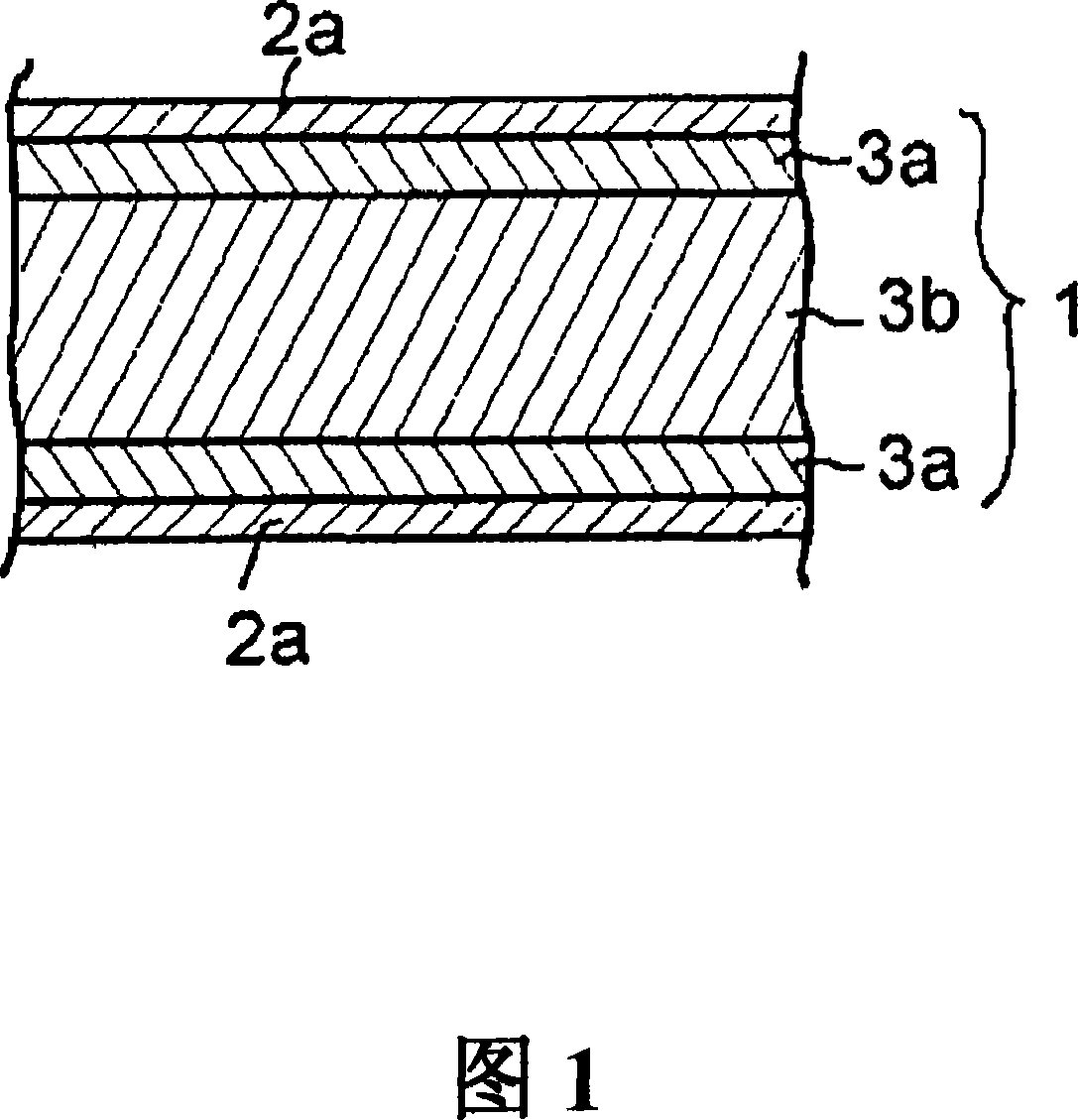

[0112] On both sides of the multilayer sheet obtained from the resin composition of Example 5, 18 μm electrolytic copper foil was pressure-laminated at a heating temperature of 220°C to manufacture polyarylene sulfide as shown in Fig. 1 Resin copper clad laminate. FIG. 1 shows a schematic cross-sectional view of the copper-clad laminate. The symbol 1 in the figure represents the extruded sheet (dielectric) with a thickness of 0.5 mm in Example 5 formed from the resin composition given in Table 2, and an electrolytic copper foil of 18 μm is laminated on both sides of the dielectric 1. 2a, 2b.

[0113] The obtained copper-clad laminate has good formability, and fully satisfies the characteristics required for the copper-clad laminate used in the field of high-frequency band electrical communication.

[0114] [Table 1]

[0115] weight%

[0116] Example 1

Example 2

Example 3

Example 4

Comparative example 1

Comparative example 2

Comparative ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com