Intelligent film coating material and method for making same

A coating film and intelligent technology, applied in polyether coatings, coatings, etc., can solve the problems of single function, difficult large-scale on-site construction, high production cost, etc., and achieve the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

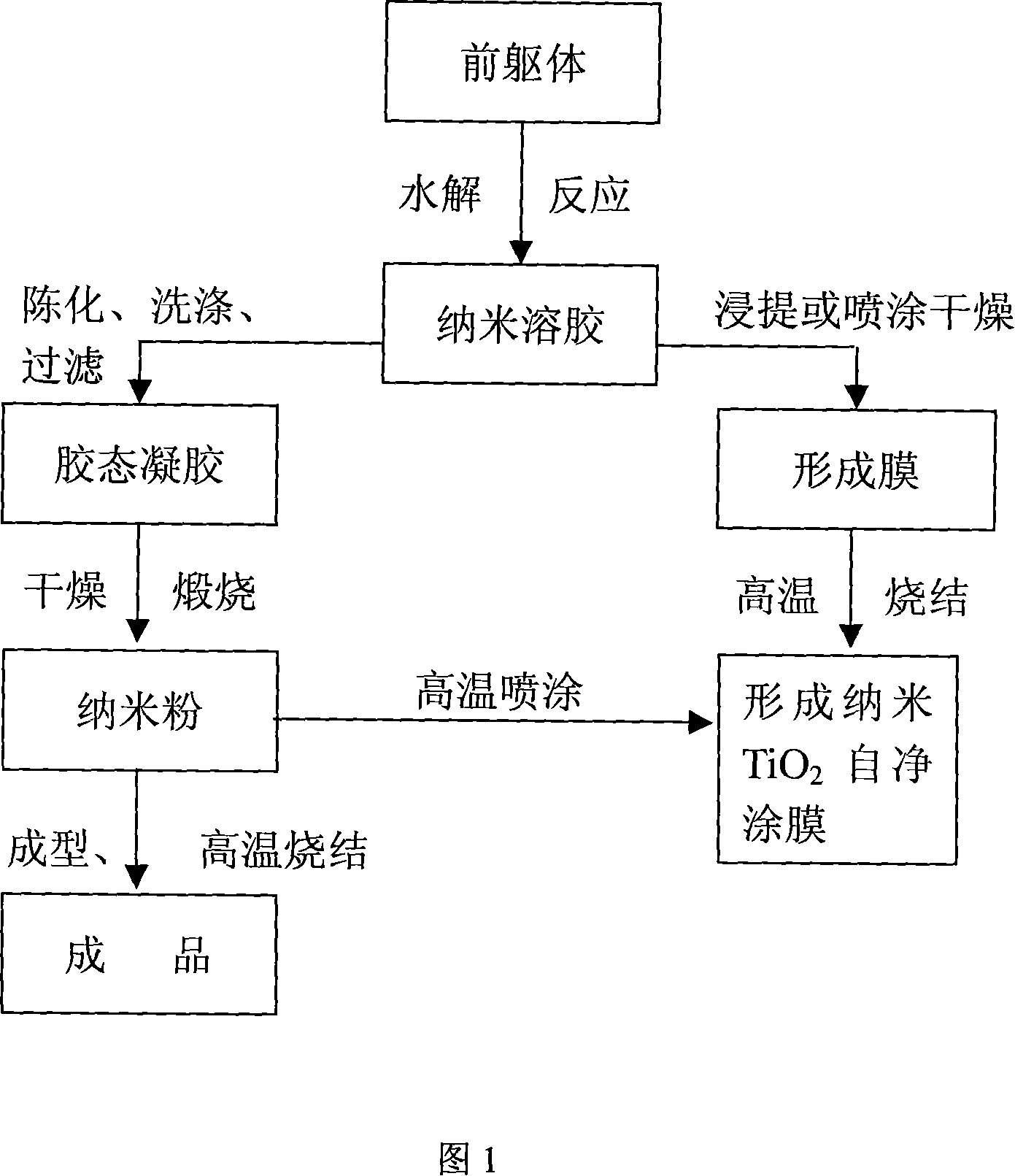

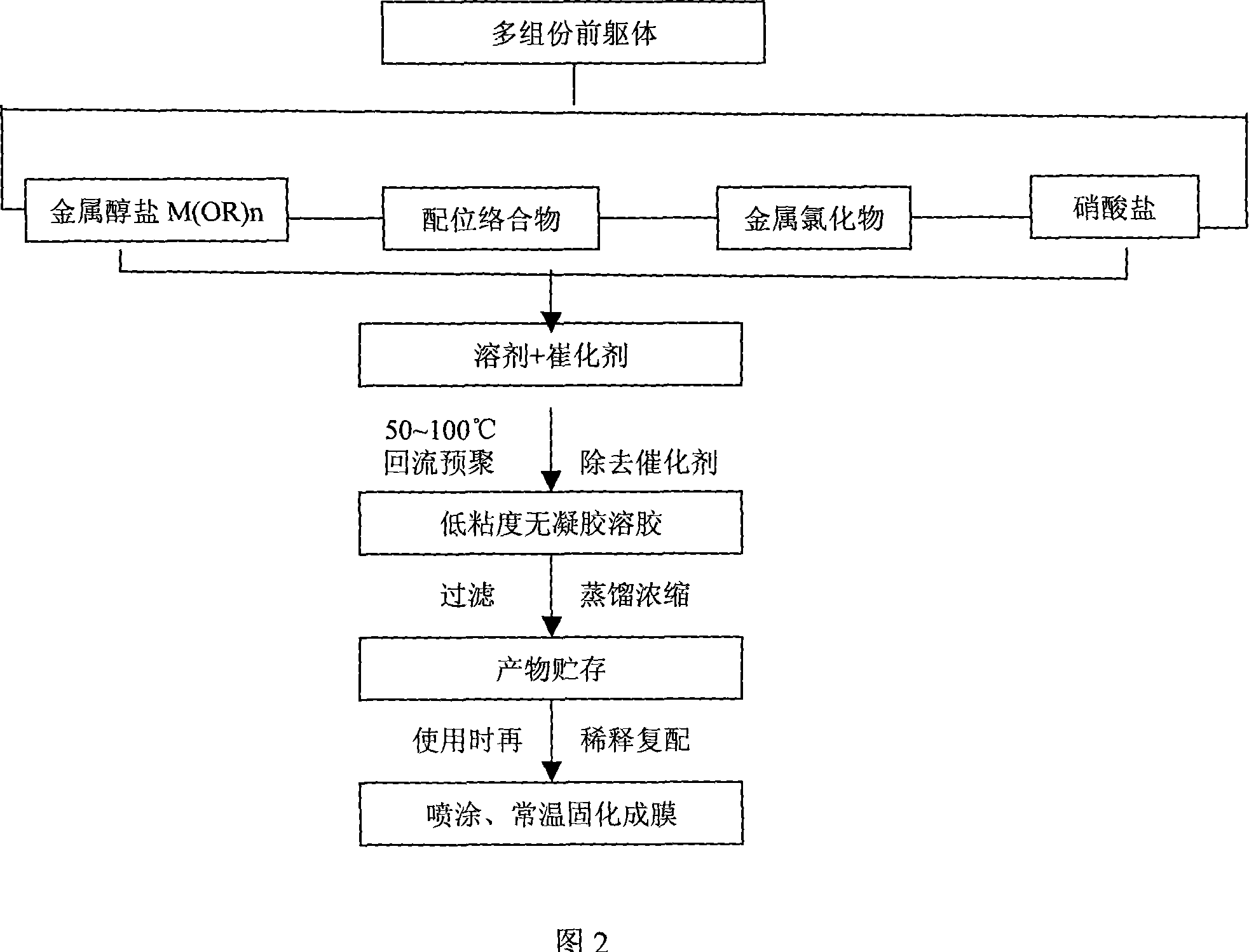

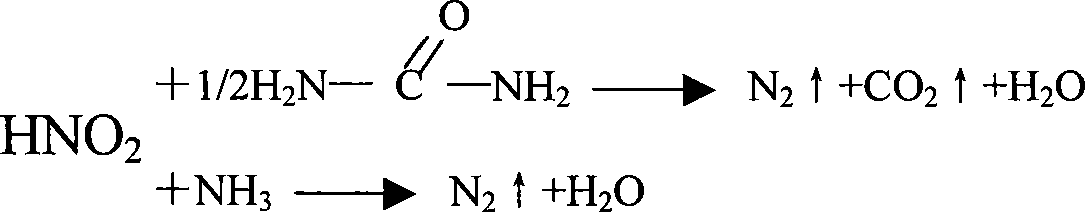

Method used

Image

Examples

Embodiment 1

[0075] Mixture of perfluoroisopropyl ether oil, medium and low viscosity alkoxy-terminated methyl silicone oil and methyl hydrogen silicone oil (ratio: 1:1:1) 5 parts

[0076] Steps:

[0077] 1. A. The transition metal alcohol M(OR)n salt is isopropyl titanate [Ti(OPr) 4 ], isopropyl vanadate [V(OPr) 4 ], cerium ethylate [Ce(OEt) 4 ], tungsten hexaethoxide [W(OEt) 6 ] and so on were dissolved in absolute ethanol, and then AcAc was added in a metered amount to make a complex solution. B. Nitrates are soluble in ethanol or water. C. Dissolve aluminum isopropoxide in absolute ethanol. D. Add ethyl orthosilicate [Si(OEt) 4 ] and other components were refluxed under nitrogen for 1-5h.

[0078] 2. After hydrolysis and condensation, the catalyst is filtered out, the filtrate is evaporated to remove the solvent, and the water is taken out, and 1-5% of water-removing agent and 0.2-3% of tin-titanium composite curing catalyst (Sn / Ti=1-1.5) are added.

[0079] Description:...

Embodiment 2

[0082] A mixture of perfluoroisopropyl ether oil, medium and low viscosity alkoxy-terminated methyl silicone oil and methyl hydrogen silicone oil (ratio 1:1:1) 5 parts of which:

[0083] 1. A. Dissolve the transition metal alkoxide in absolute ethanol, and then add AcAc according to the metered amount to make a complex solution. B. Nitrates are soluble in ethanol or water. C. Dissolve aluminum isopropoxide in absolute ethanol. D. Adding prefabricated functional colloidal tetraethyl orthosilicate [Si(OEt) 4 ] and other components were refluxed under nitrogen for 3h.

[0084] 2. After hydrolysis and condensation, the catalyst is filtered out, the filtrate is evaporated to remove the solvent, and the water is taken out, then anhydrous solvent is added to dilute to 10-30%, and water remover is added to 1-5%, tin-titanium composite curing catalyst (Sn / Ti =1-1.5), 0.2-3%.

preparation example

[0085] The following is an example of functional sol preparation: there are two methods for the preparation of photocatalytic sensing sol in Example 2

[0086] (1)

[0087] Prebody composition

parts by mass

Prebody composition

parts by mass

227

Deionized water

15-20

Molybdenum ethanol

15

Orthoethyl silicate Si(OEt) 4

104

216

Strongly acidic cation exchange resin

15

Absolute ethanol

500

[0088] The operation steps are the same as Example 1. Among them, tungsten ethoxide [W(OEt) 6 ] and molybdenum ethoxide [Mo(OEt) 6 ] dissolved in absolute ethanol, add acetylacetone and mix well, then add ethyl silicate [Si(OEt) 4 ], water, in N 2↑ Reflux for 1-5 hours, filter off the catalyst, distill off the ethanol (bring out the water), then dilute to 30-50% with anhydrous alcohol, and store it for later use.

[0089] (2)

[0090] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com