Oxynitrides luminescent material and illuminating or exhibiting light source produced thereby

A technology of nitrogen oxide compounds and luminescent materials, which is applied in the directions of luminescent materials, energy-saving lighting, chemical instruments and methods, etc., can solve the problems that the luminous intensity of phosphors needs to be further improved, the mass production cannot be realized, and the synthesis process is complicated, and the realization is easy to achieve. The effect of mass production, wide excitation spectral range and high color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

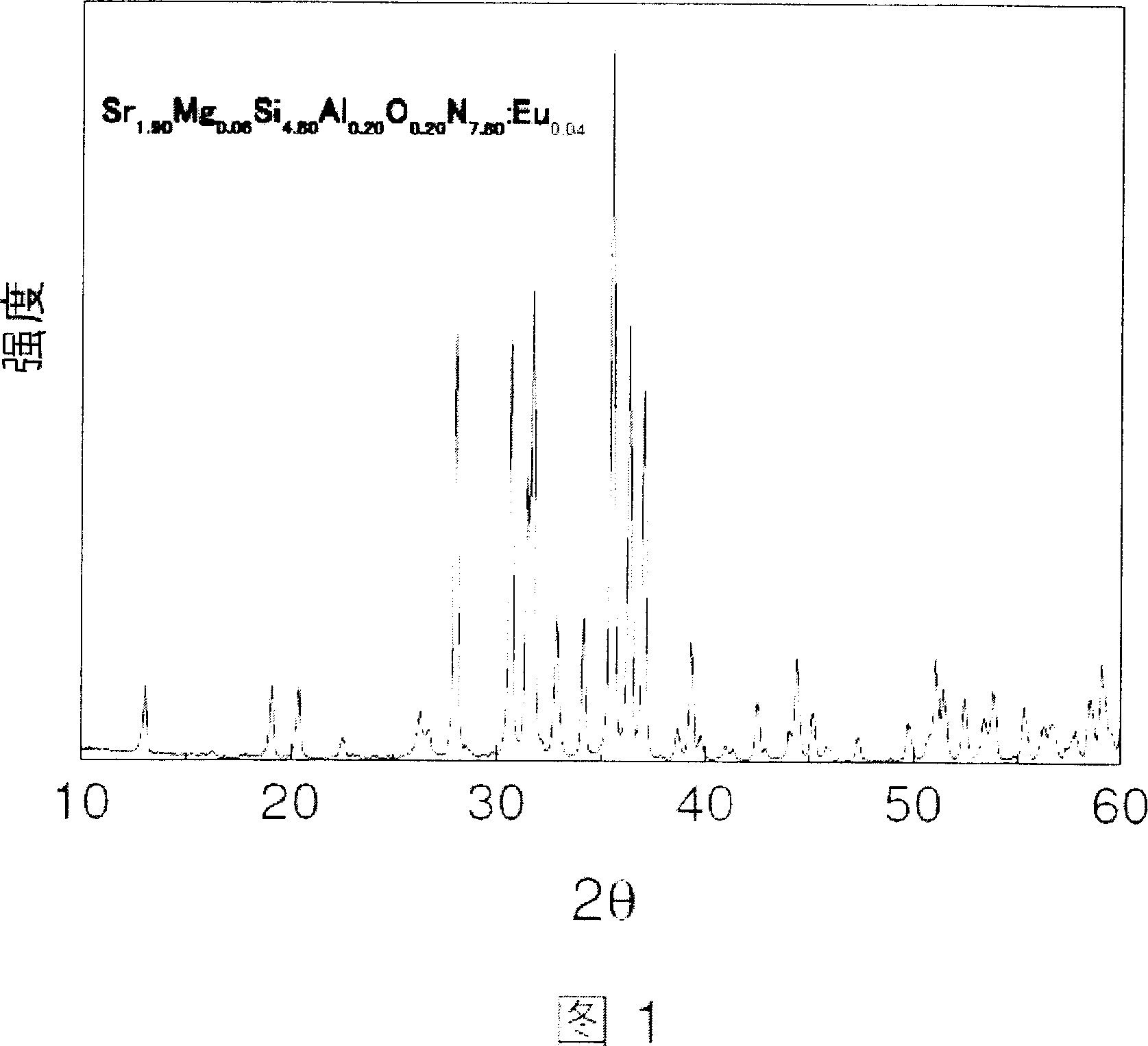

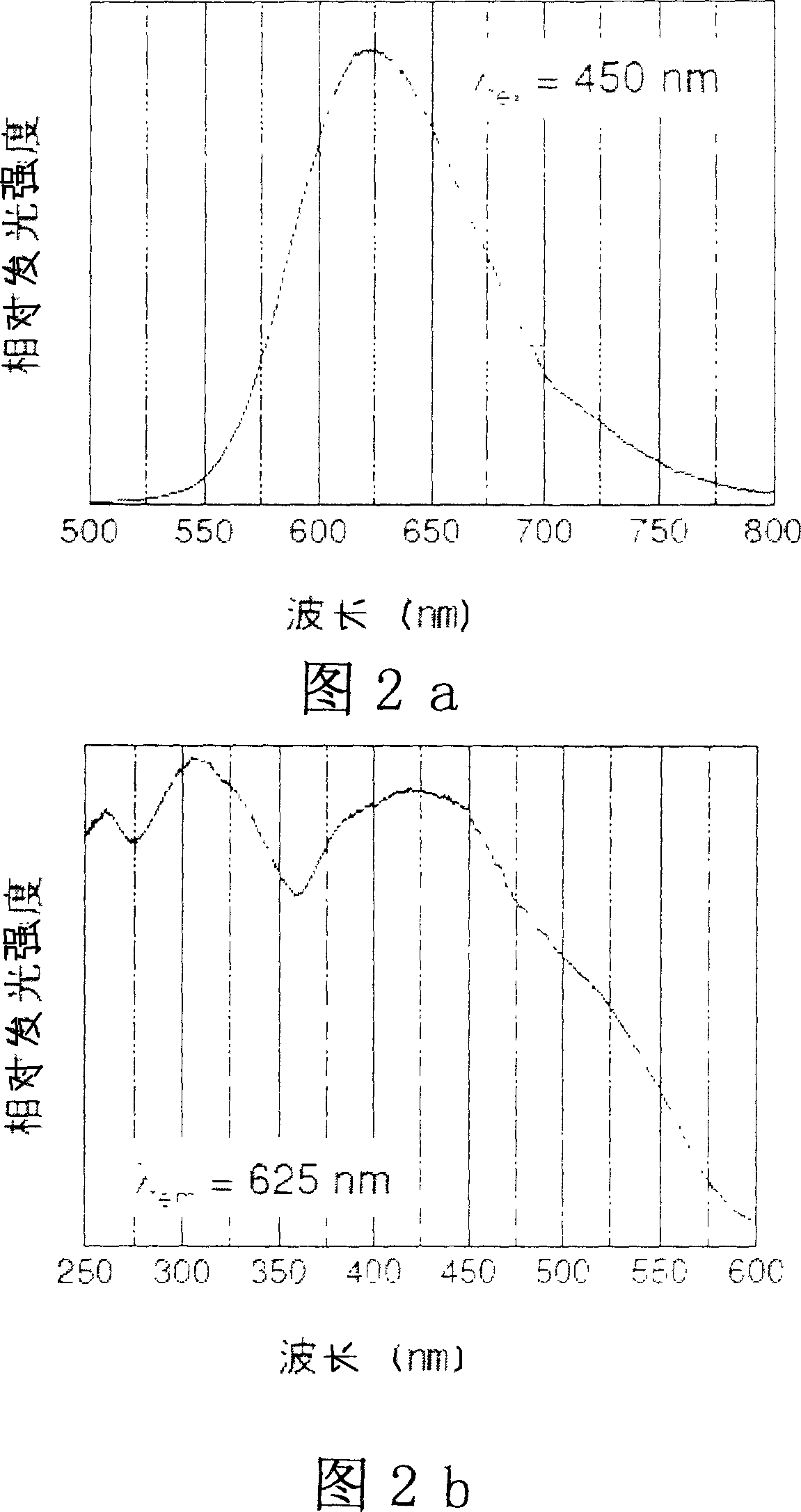

[0050] Example 1: Sr 1.90 Mg 0.06 Si 4.80 Al 0.20 o 0.20 N 7.80 :Eu 0.04 Preparation example of luminescent material (solid phase reaction method)

[0051] Weigh Sr according to the above composition 3 N 2 (43.1932 grams), Mg 3 N 2 (0.4671 g), Si 3 N 4 (52.3152 g), Al 2 o 3 (2.3822 g) and Eu 2 o 3 (1.6442 grams), after mixing and grinding in the glove box, pack the boron nitride crucible and roast in the tube furnace, feed N under normal pressure 2 / H 2 (95% / 5%), the flow rate is 2 liters / minute, with 0.1gSrF 2 It is used as a flux, and it is kept at 1400°C for 4 hours. The obtained powder is ground and then fired at a high temperature under the same conditions to promote the development of grains. The obtained luminescent material was pulverized, washed with hydrochloric acid to remove impurities, and dried to obtain 100 g of the red luminescent material of the present invention. Its X-ray diffraction pattern is shown in Figure 1, it can be seen from the fi...

Embodiment 2-7

[0053] The corresponding raw materials are weighed according to the chemical formula composition and stoichiometry listed in each embodiment in Table 1, and the preparation process is the same as in Example 1, wherein the reaction flux used is the chloride of A, and the luminous intensity of the obtained luminescent material is shown in Table 1.

[0054] Table 1 Chemical formulas and luminescent properties of Examples 1-7 (excitation wavelength is 450nm)

[0055] Example

Embodiment 8

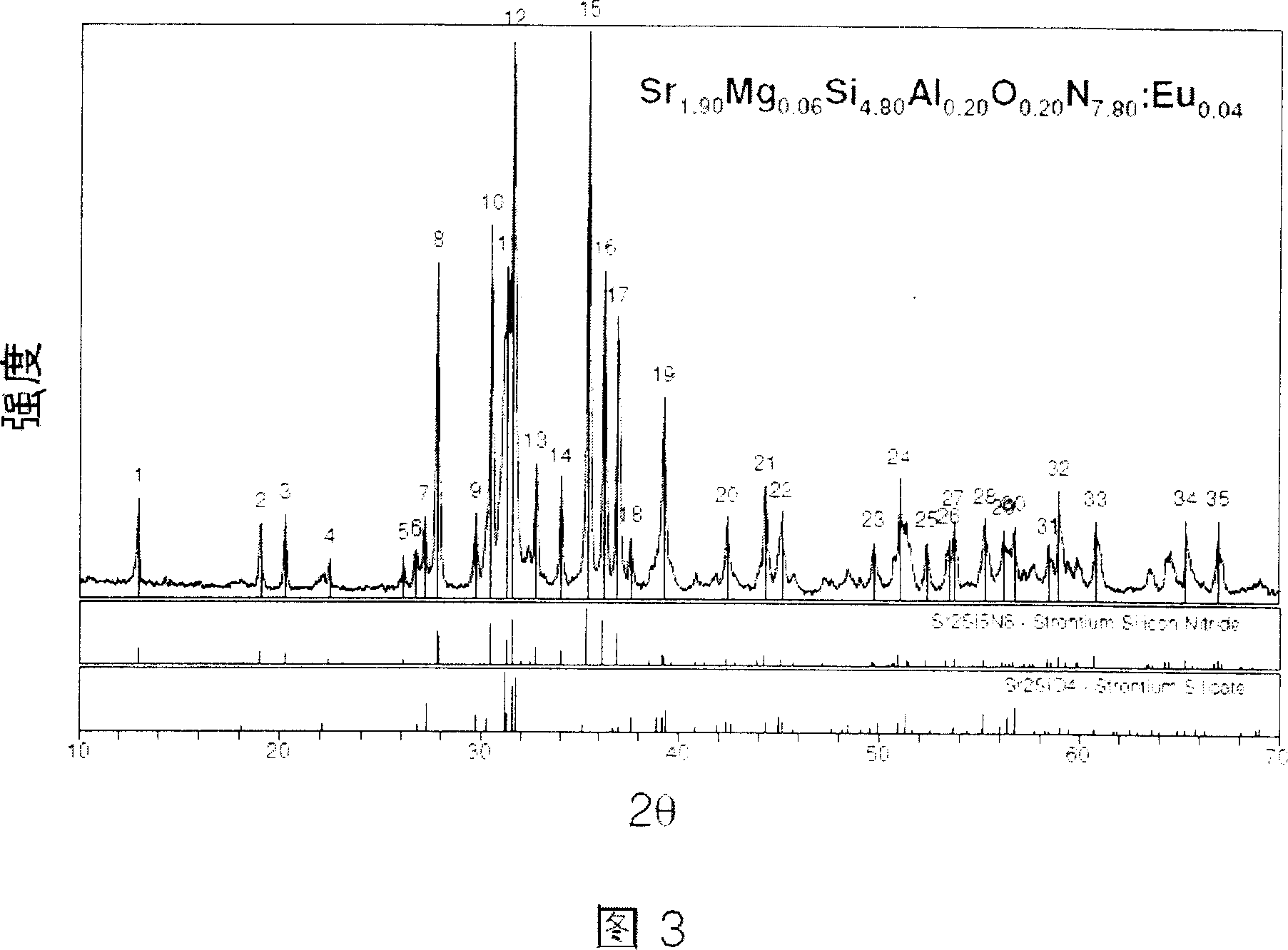

[0056] Example 8: Sr 1.90 Mg 0.06 Si 4.80 Al 0.20 o 0.20 N 7.80 :Eu 0.04 Preparation example of luminescent material (pressure sintering method)

[0057] Weigh SrCO according to the above composition 3 (53.5782 grams), MgO (0.573 grams), Si 3 N 4 (42.6797 g), Al 2 o 3 (1.9434 g) and Eu 2 o 3 (1.3413 grams), after adding n-hexane mixed grinding evenly, pack into boron nitride crucible and carry out roasting in pressure furnace, feed the N of 10 atmospheric pressures 2 , kept at 1500° C. for 6 hours, and the resulting luminescent material was crushed, pickled to remove impurities, and dried to obtain 100 g of the red luminescent material of the present invention. From the point of view of the preparation process, the synthesis method is simple, the raw material cost is low and the chemical stability is good, and no mixing operation in a glove box is required, so that low-cost and mass production can be realized. Its X-ray diffraction pattern is shown in Figure 3, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com