Process for producing molded object of curable resin and molded cured resin

A curable resin and a technology for a manufacturing method, which are used in the manufacture of curable resin molded bodies and the fields of cured resin molded bodies, can solve the problem of poor releasability, confusion of fine concavo-convex shapes in curable resin molded bodies, and inability to sufficiently transfer concave-convex shapes and other problems, to achieve the effect of suppressing the reduction of transferability and mold releasability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0180] Hereafter, although an Example and a comparative example demonstrate this invention in more detail, this invention is not limited to an Example.

[0181] In addition, in the following examples, unless otherwise specified, parts and % are based on weight, and pressure is gauge pressure.

[0182] In the following production examples and examples, the measurement methods of various physical properties are as follows.

[0183] [Weight average molecular weight (Mw)]

[0184] It is measured by gel permeation chromatography (GPC) using cyclohexane as a solvent, and is a value obtained in terms of polyisoprene.

[0185] [Hydrogenation rate (%) of main chain and hydrogenation rate of aromatic ring (nuclear hydrogenation rate (%))]

[0186] pass 1 H-NMR determination.

[0187] [Glass transition temperature (Tg(°C))]

[0188] It measures according to JIS-K 7121 using a differential scanning calorimeter under the condition of a temperature increase rate of 10° C. / min.

[0189...

manufacture example 1

[0207] Under a nitrogen atmosphere, in a reactor at room temperature, after adding 0.82 parts of 1-hexene, 0.15 parts of dibutyl ether and 0.30 parts of triisobutylaluminum to 500 parts of dehydrated cyclohexane and mixing them, the temperature was maintained at 45 ℃, 170 parts tricyclic [4.3.0.1 2,5 ] deca-3,7-diene (common name: dicyclopentadiene, hereinafter referred to as "DCP"), 30 parts of 8-ethyl-tetracyclo[4.4.0.1 2,5 .1 7,10 ] Dodec-3-ene (hereinafter abbreviated as "ETCD") and 80 parts of tungsten hexachloride (0.7% toluene solution) were continuously added over 2 hours to polymerize. Next, 1.06 parts of butyl glycidyl ether and 0.52 parts of isopropanol were added to the polymerization solution to deactivate the polymerization catalyst and stop the polymerization reaction. When the obtained reaction solution containing the DCP / ETCD ring-opened copolymer was analyzed by gas chromatography, the polymerization conversion rate of each monomer was 99.5%.

[0208] Next...

manufacture example 2-1

[0211] To 100 parts of the alicyclic structure-containing polymer (particle PM) obtained in Production Example 1, 0.05 part of soft polymer (manufactured by Asahi Kasei Co., Ltd., Toughtec H1052) and 0.3 part of 1,6-hexyl Diol bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] (manufactured by Ciba-Geigy, Irganox 259), with a twin-shaft mixer (manufactured by Toshiba Machinery Co., Ltd. TEM- 35B, screw diameter 37mm, L / D=32, screw rotation speed 250rpm, resin temperature 240°C, filling rate 10kg / hour) kneading and extrusion to obtain pellets P1 of the resin composition. The glass transition temperature of the particle P1 is 100°C.

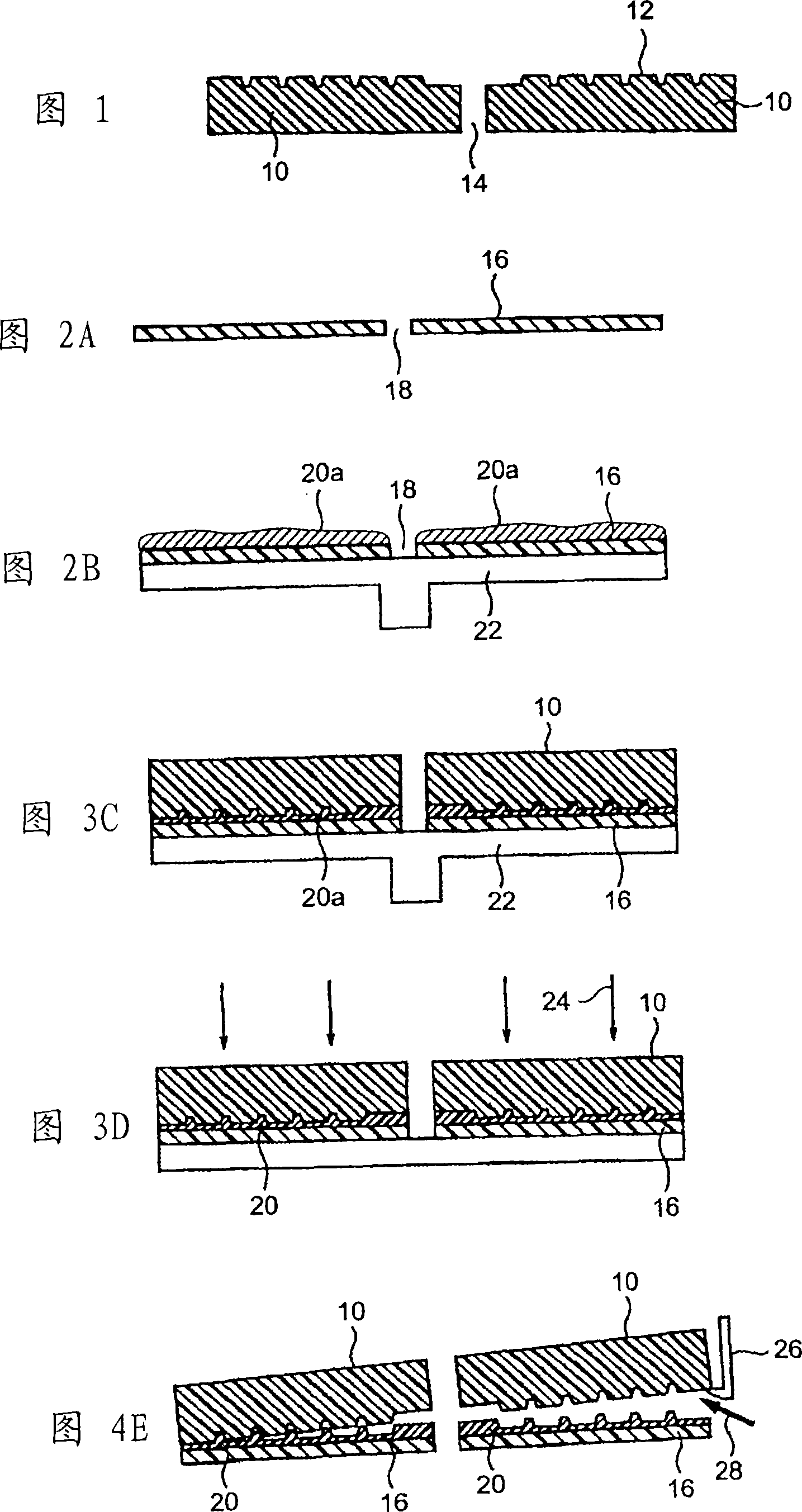

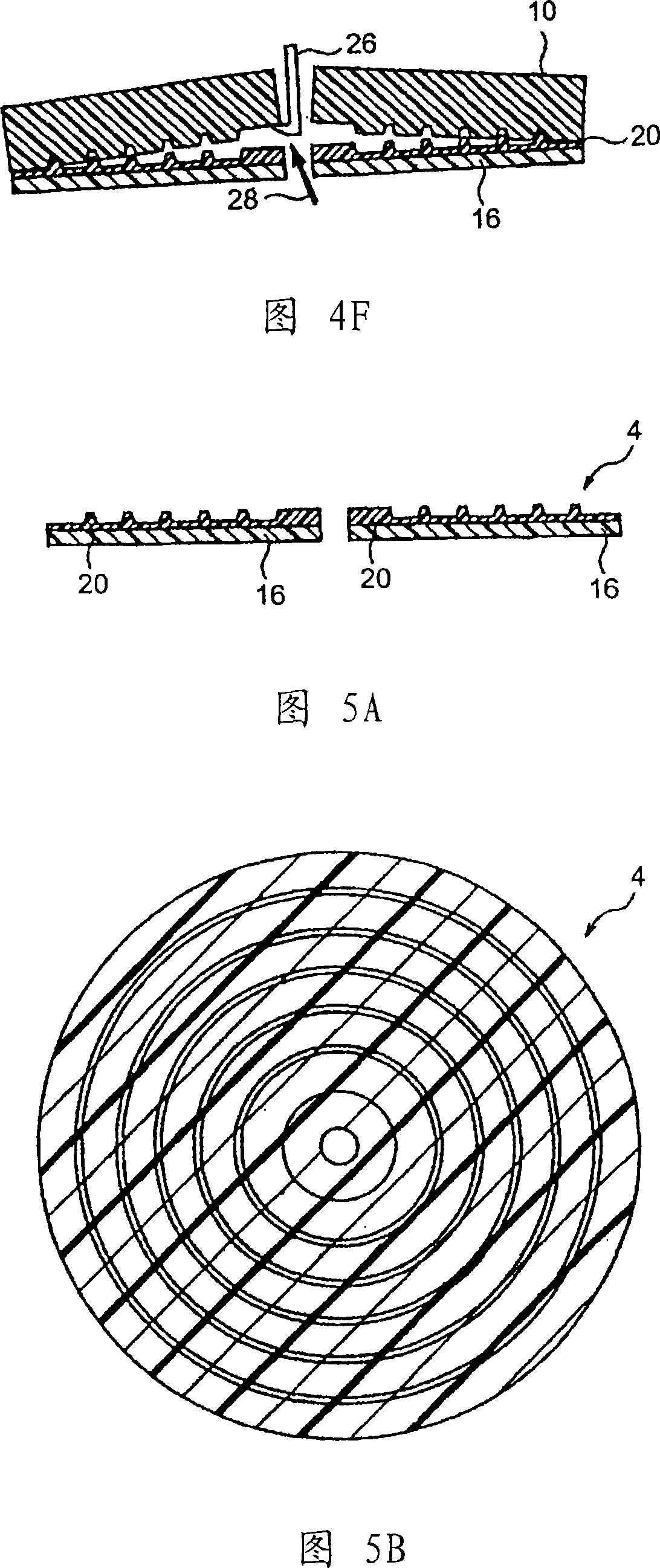

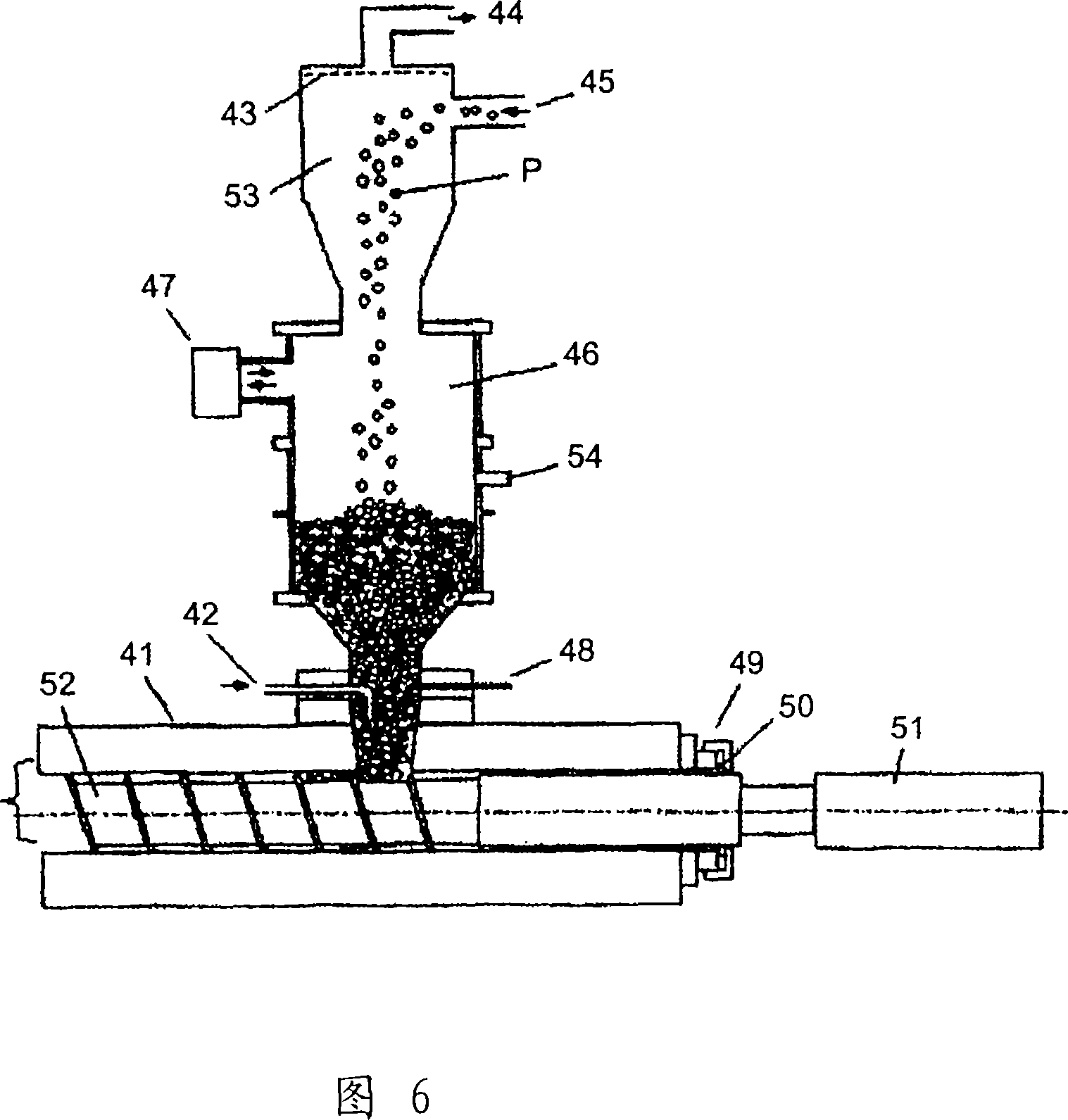

[0212] The obtained pellets P1 were molded using the resin molding apparatus shown in FIG. 6 to obtain five resin molds S1 (diameter 120 mm, thickness 0.6 mm) for curable resin having the structure shown in FIG. 1 .

[0213]The resin molding device shown in FIG. 6 is a thermoplastic resin including an air-carrier type resin delivery device (not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com