Technique for cutting horizontal gallium arsenide single-crystal wafer with inside diameter slicer

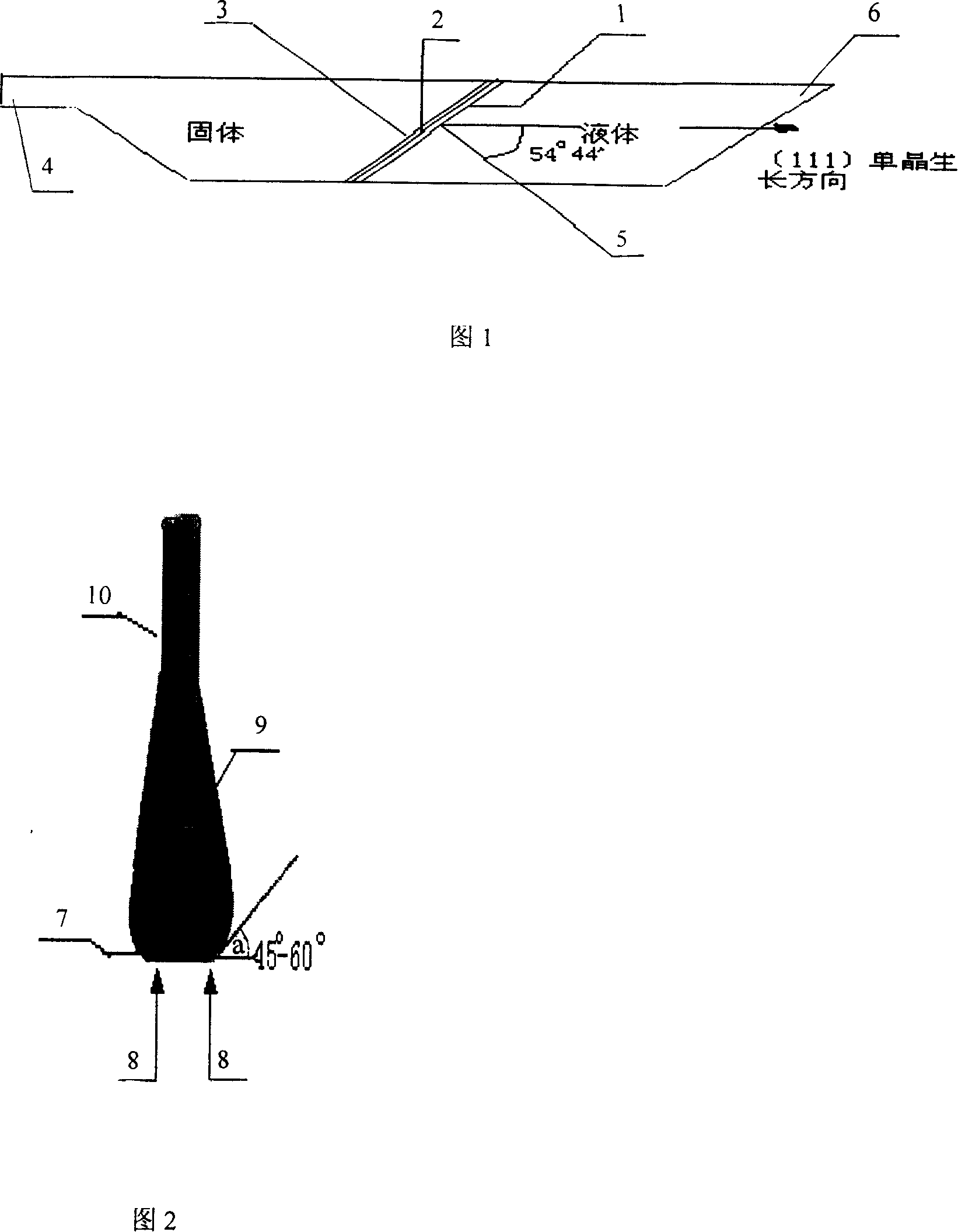

A technology of inner circle slicing and gallium arsenide, which is applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of difficult control of mechanical stress and thermal stress residual stress of horizontal GaAs wafers, and achieve production stability and Good repeatability, good surface finish, and optimized cutting conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specifications for cutting horizontal gallium arsenide wafers by adopting the process of the invention are: crystal orientation (100)±0.5°, diameter Φ50.8mm, thickness 470±50um, round wafer.

[0039] 1. Equipment and equipment technical indicators:

[0040] TS type horizontal air bearing rotary table (cutting angle up to 61 degrees) inner circle slicer (this equipment is produced and sold by Meyerberg, Switzerland).

[0041] Blade type: Φ422mm, blade thickness: 300um Material: stainless steel knife base, nickel alloy emery plated

[0042] Blade inner diameter tensor: 0.85mm-1.05mm, concentricity ≤0.002mm

[0043] Circular run-out deviation of knife ring end face: ≤0.006mm

[0044] Radial runout deviation of cutter ring: ≤0.03mm

[0045] Radial runout of blade positioning pin: ≤0.015mm

[0046] Workpiece feed accuracy (step error) ±0.005mm

[0047] 2. Process conditions

[0048] Blade speed: 1100-1600r / min

[0049] Cutting speed: 20-30mm / min

[0050] Coolant: demineraliz...

Embodiment 2

[0064] The specifications for cutting horizontal gallium arsenide wafers using the process technology of the present invention are: crystal orientation (100) offset (110) ± 0.5°, diameter Φ 63.5 mm, thickness 350 ± 50um, round wafer.

[0065] 1. Equipment and equipment technical indicators:

[0066] TS type horizontal air-bearing rotary table (with an angle of up to 61 degrees) inner circle slicer.

[0067] Blade type: Φ422mm, blade thickness: 300um Material: stainless steel knife base, nickel alloy emery plated

[0068] Blade inner diameter tensor: 0.9mm-0.95mm, concentricity ≤0.002mm

[0069] Circular runout deviation of the knife ring end face: ≤0.0055mm

[0070] Radial runout deviation of cutter ring: ≤0.025mm

[0071] Radial runout of blade positioning pin: ≤0.015mm

[0072] Workpiece feed accuracy (step error) ±0.005mm

[0073] 2. Process conditions

[0074] Blade speed: 1100-1400r / min

[0075] Cutting speed: 15-30mm / min

[0076] Coolant: demineralized water (industrial pure...

Embodiment 3

[0082] The specifications for cutting horizontal gallium arsenide wafers using the process technology of the present invention are: crystal orientation (100) offset (011) ±0.1°, diameter Φ63.5mm-76mm, thickness 280±20um, round wafer.

[0083] 1. Equipment and equipment technical indicators:

[0084] TS type horizontal air-bearing rotary table (with an angle of up to 61 degrees) inner circle slicer.

[0085] Blade inner diameter tensor: 0.95mm-1.05mm, concentricity ≤0.002mm

[0086] Circular runout deviation of the knife ring end face: ≤0.005mm

[0087] Radial runout deviation of cutter ring: ≤0.02mm

[0088] Radial runout of blade positioning pin: ≤0.015mm

[0089] Workpiece feed accuracy (step error) ±0.005mm

[0090] 2. Process conditions

[0091] Blade speed: 1100-1250r / min

[0092] Cutting speed: 10-25mm / min

[0093] Coolant: demineralized water (industrial pure water)

[0094] Coolant temperature: 10-20℃

[0095] Coolant flow: 600-650ml / min

[0096] Cutting workpiece: the qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com